Flexible circuit board production wastewater discharge process

A technology for flexible circuit boards and production wastewater, which is applied in metallurgical wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., and can solve problems such as discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

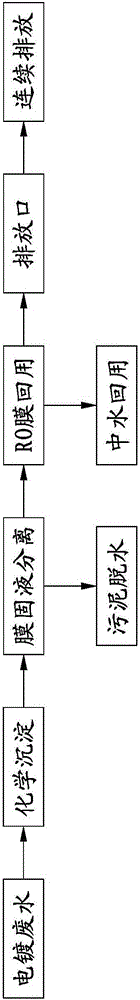

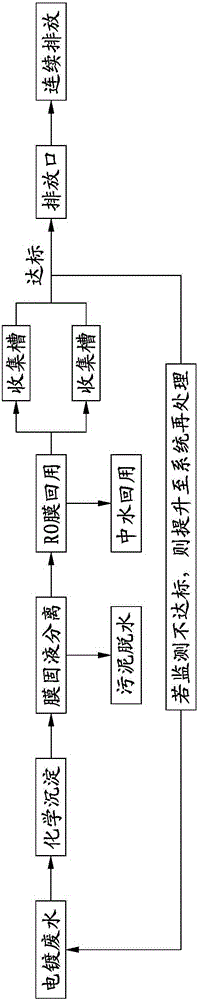

[0020] like figure 2 Shown, the present invention is a kind of flexible circuit board production wastewater discharge process, comprises the following steps:

[0021] (1) Chemical precipitation: Sodium hydroxide is added to the electroplating wastewater to adjust the electroplating wastewater to alkaline, that is, after the pH value is adjusted from 2-3 to 8-9, the copper ions in the wastewater combine with hydroxide ions to form copper hydroxide, and at the same time Add flocculant polyaluminum chloride (PAC) to make the copper hydroxide granulate into large particles, naturally decompose, and obtain decomposed electroplating wastewater;

[0022] (2) Membrane solid-liquid separation: The electroplating wastewater after reduction is subjected to solid-liquid separation through the polymer membrane material, and the electroplating wastewater passing through the membrane is the electroplating wastewater that has been treated up to the standard. At the same time, the solid coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com