High-power yttrium-gadolinium garnet ferrite

A garnet and ferrite technology, which is applied in the field of microwave technology and magnetic materials, can solve the problems of large material loss and low material dielectric constant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] According to chemical formula

[0022] SM x Y 3-x-y-2z-p-q-q′ Gd y Ca 2z+p+q+q′ V z Ge p sn q Ti q′ In q″ Al w mn w′ Fe 5-z-p-q-q′-q″-w-w′-δ o 12

[0023] Take: x=0.01; y=1.10; z=0.25; p=0; q=0; q′=0.05; q″=0.25; w=0.14; w′=0; and calculate the amount of raw materials required .Use Sm with purity ≥99.9% 2 o 3 ,Y 2 o 3 ,Gd 2 o 3 and analytically pure Fe 2 o 3 , CaCO 3 , V 2 o 5 ,In 2 o 3 , TiO 2 ,Al(OH) 3 As the raw material, weigh out the corresponding weight of the raw material. Mixed by ball milling, pre-fired at 1200°C, heat preservation for 4 hours, and then ball milled twice, after molding, sintered at 1350°C, heat preservation for 5 hours. The sintered samples were ground and made into small balls and rods required for measurement, and carried out parameter tests. The measurement results are shown in Table 1.

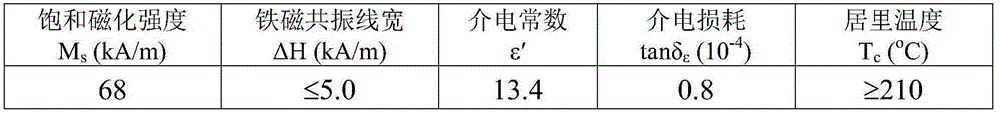

[0024] Table 1 Example 1 Electromagnetic performance parameters of 850G high-power garnet material

[0025]

Embodiment 2

[0027] According to chemical formula

[0028] SM x Y 3-x-y-2z-p-q-q′ Gd y Ca 2z+p+q+q′ V z Ge p sn q Ti q′ In q″ Al w mn w′ Fe 5-z-p-q-q′-q″-w-w′-δ o 12

[0029] Take: x=0.02; y=0.58; z=0; p=0; q=0.15; q′=0.03; q″=0; w=0; w′=0, calculate the amount of raw materials needed. Sm with purity ≥99.9% 2 o 3 ,Y 2 o 3 ,Gd 2 o 3 and analytically pure Fe 2 o 3 , CaCO 3 , SnO 2 , TiO 2 As the raw material, weigh out the corresponding weight of the raw material. Mixed by ball milling, pre-fired at 1250°C, heat preservation for 4 hours, and then ball milled twice, after molding, sintered at 1400°C, heat preservation for 5 hours. The sintered samples were ground and made into small balls and rods required for measurement, and carried out parameter tests. The measurement results are shown in Table 2.

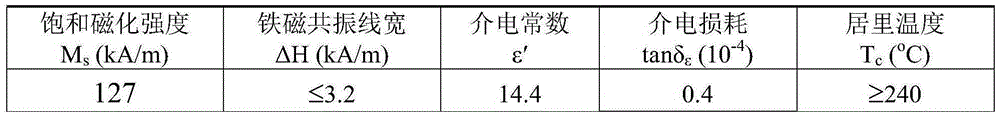

[0030] Table 2 Electromagnetic parameters of Example 2 Sm,Ti:YGdIGs high power garnet material

[0031]

example 3

[0033] According to chemical formula

[0034] SM x Y 3-x-y-2z-p-q-q′ Gd y Ca 2z+p+q+q′ V z Ge p sn q Ti q′ In q″ Al w mn w′ Fe 5-z-p-q-q′-q″-w-w′-δ o 12

[0035] Take: x=0.01; y=1.20; z=0.28; p=0.10; q=0.25; q′=0.05; q″=0; w=0; w′=0.04, calculate the amount of raw materials needed. Use Sm with purity ≥99.9% 2 o 3 ,Y 2 o 3 ,Gd 2 o 3 and analytically pure Fe 2 o 3 ,CaCO 3 ,GeO 2 ,V 2 o 5 ,SnO 2 , TiO 2 ,MnCO 3 As the raw material, weigh out the corresponding weight of the raw material. Mixed by ball milling, pre-fired at 1200°C, heat preservation for 4 hours, and then ball milled twice, after molding, sintered at 1330°C, heat preservation for 5 hours. The sintered samples were ground and made into small balls and rods required for measurement, and carried out parameter tests. The measurement results are shown in Table 3.

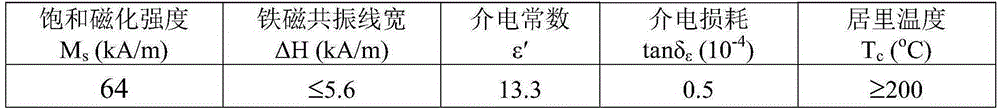

[0036] Table 3 Example 3 Electromagnetic parameters of Sm,Ti:YGdCaVIG high power garnet material

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com