A kind of preparation method of composite material graphite heater for high temperature

A graphite heater and composite material technology, applied in induction heating, ohmic resistance heating, heating element materials, etc., can solve problems such as damage, deterioration of crucibles or heated elements, and achieve the effect of preventing carbon volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

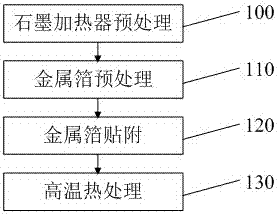

[0020] Example: refer to figure 1 , a method for preparing a composite graphite heater for high temperature is carried out according to the following steps:

[0021] Step 100 (A), graphite heater pretreatment: polishing the inner surface of the graphite heater to make the surface smooth and mirror-like, and then cleaning the inner and outer surfaces.

[0022] Step 110 (B), tantalum foil pretreatment: use a rolling machine to roll the tantalum foil to ensure that the surface of the tantalum foil is smooth, and then pickle and wash the metal foil. In this embodiment, pickling with a concentration of 20% Dilute hydrochloric acid, washed with deionized water to ensure the cleanliness of the metal foil.

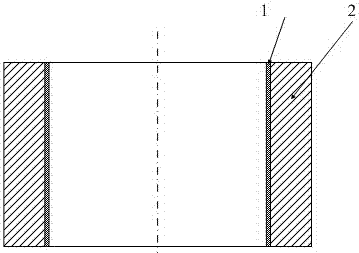

[0023] Step 120 (C), attaching the tantalum foil: attaching the tantalum foil to the inner surface of the graphite heater, as far as possible to ensure that the tantalum foil is completely attached, and the tantalum foil does not bulge.

[0024] Step 120 (D), high-temperature he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com