A preparation method of composite crucible used at ultra-high temperature

A composite type, crucible technology, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of high brittleness and easy cracking of carbide materials, and achieve the elimination of differences in the degree of carbonization and stress in the crucible Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

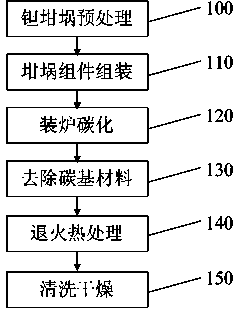

[0020] Example: refer to figure 1 , a method for preparing a composite crucible used at an ultra-high temperature is carried out according to the following steps:

[0021] Step 100 (A), pretreatment of the tantalum crucible: soak the original tantalum crucible in the sulfuric acid solution container, completely submerged, heat the sulfuric acid solution container on an electromagnetic cooker until the sulfuric acid solution is boiling, and soak in the sulfuric acid solution boiling state for 60 minutes After cooling, the tantalum crucible was taken out, rinsed with deionized water, and dried with nitrogen.

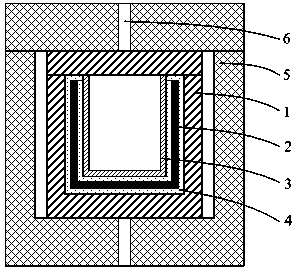

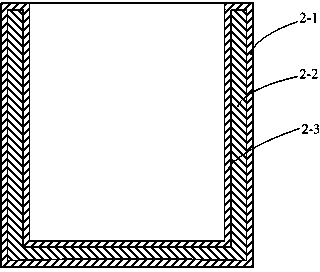

[0022] Step 110 (B), crucible assembly: place the tantalum crucible 2 in the graphite crucible 1, and then place the graphite cup 3 in the tantalum crucible 2, the wall thickness of the graphite cup 3 is 2 mm, and the inner wall of the graphite crucible 1 and the outer wall of the tantalum crucible 2 The distance between the inner wall of the tantalum crucible 2 and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com