Preparation method of dimethyl ethyl aminobenzoate midbody nitrobenzoic acid ethyl ester

A technology of ethyl dimethylaminobenzoate and ethyl nitrobenzoate, which is applied in the field of preparation of ethyl dimethylaminobenzoate intermediate p-nitrobenzoate, to reduce the amount of three wastes and reduce the cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The reaction equation of preparing ethyl dimethylaminobenzoate intermediate p-nitrobenzoate of the present invention is as follows:

[0022] .

[0023] Concrete preparation steps are:

[0024] Add 15kg of p-nitrobenzoic acid and 60kg of ethanol into a 100L reactor, stir and dissolve, pump the metering pump into the first-stage fixed bed (temperature: 50-80°C) pre-installed with HY type solid acid catalyst, and the material coming out The content is controlled at more than 80%, and then pumped into the second-stage fixed-bed reactor (temperature 80-150°C) with a metering pump, and the content of the material coming out is more than 98%.

[0025] Put the material into the desolventizer, separate the excess ethanol and water, add 5% sodium carbonate solution to wash, wash off the excess raw material at 70-80°C, add water to disperse, centrifuge, and dry to obtain the finished product with a yield of more than 96%. .

Embodiment 2-5

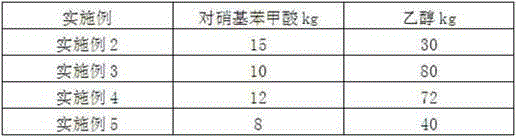

[0027] The proportioning ratio of p-nitrobenzoic acid and ethanol in Examples 2-5 is shown in Table 1 below, and the other steps are the same as in Example 1, and the yields are all above 96%.

[0028]

[0029] The present invention adopts a super strong solid acid as a catalyst, and obtains the target product through the preparation method of continuous esterification in a fixed-bed reactor, which solves the problem of producing a large amount of waste acid and high-salt waste water in the existing industrial production, and greatly reduces waste water production. emission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com