Soft coating applicable to tape measure and preparation method and application thereof

A soft and coating technology, applied in the field of coatings, can solve the problems of not being able to balance adhesion and flexibility, and achieve the effect of good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

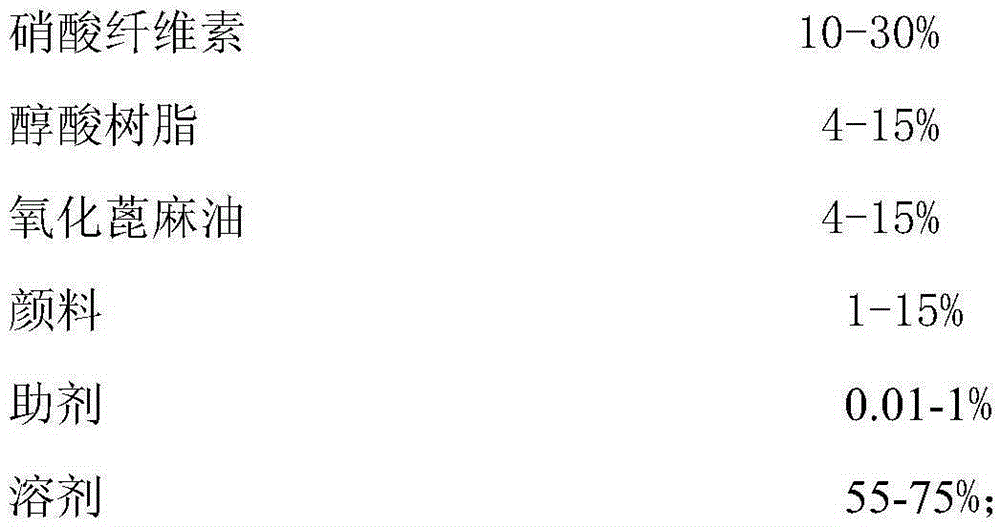

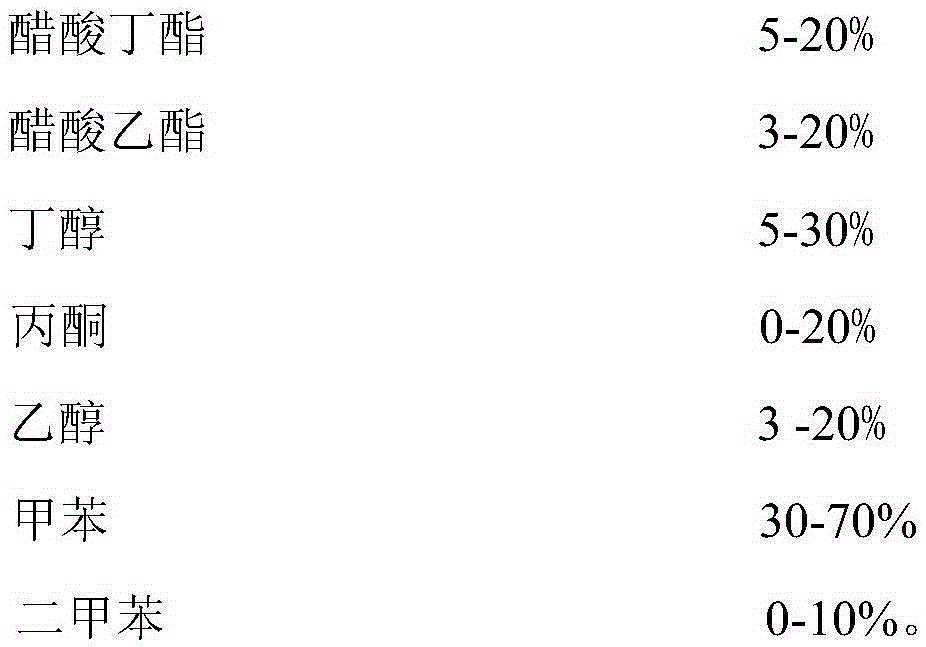

Method used

Image

Examples

Embodiment 1

[0035] Weigh 128.7 grams of rutile titanium dioxide powder, 4.70 grams of oxidized castor oil, 0.37 grams of organic bentonite, 0.185 grams of BYK-ATU, 3.145 grams of xylene, stir evenly, and then use a three-roller to mill pulp to a fineness below 15 μm to form a color paste. spare. 103.2 grams of butyl acetate, 38.7 grams of ethyl acetate, 77.2 grams of butanol, 51.6 grams of acetone, 51.6 grams of ethanol, 322 grams of toluene, 120.3 grams of 80″ (12.2%) nitrocellulose and 56 grams of 349 alkyd resin in order Put it into the paint mixing tank, mix evenly, slowly add the ground color paste into the container of the above premixed material under stirring, and then get a white tape soft paint solution, take a sample on the surface of the metal sample for coating, and then quickly dry it Dry to form a film, filter and pack after the performance test (parameters are shown in Table 2) is qualified.

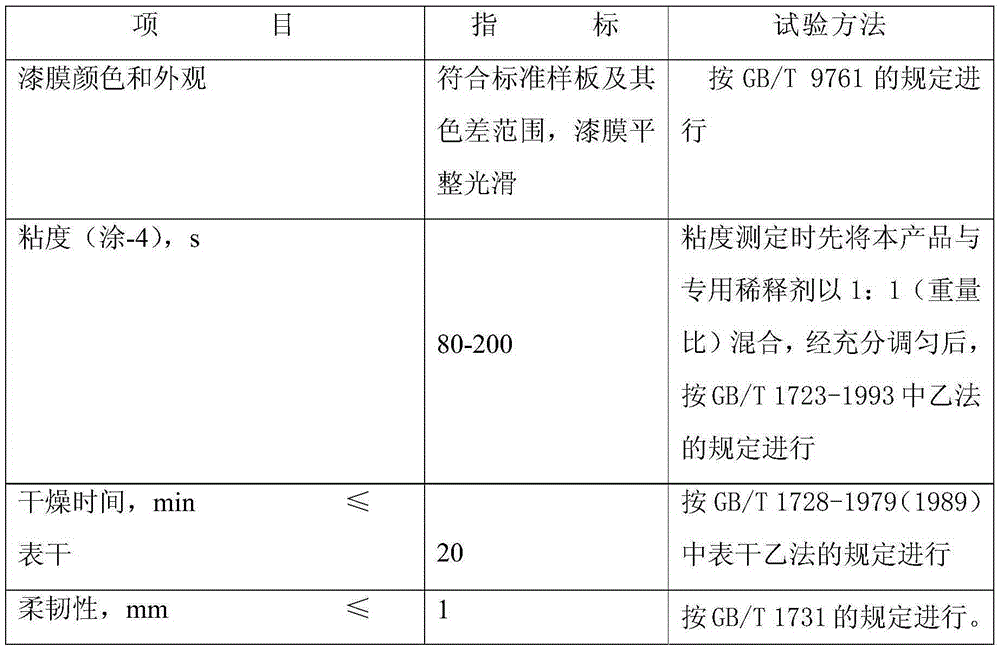

[0036] Table 2

[0037]

Embodiment 2

[0039] Weigh 10.5 grams of N220 carbon black powder, 52.2 grams of oxidized castor oil, and 1.3 grams of BYK-ATU, stir evenly, and then use a three-roller to mill the pulp to a fineness of less than 15 μm to form a color paste for later use. 109.8 grams of butyl acetate, 41.2 grams of ethyl acetate, 82.4 grams of butanol, 54.9 grams of acetone, 54.9 grams of ethanol, 343.2 grams of toluene, 132 grams of 80″ (12.2%) nitrocellulose, 61.6 grams of 349 alkyd resin in order Put it into the paint mixing tank, mix evenly, slowly add the ground color paste into the container of the above premixed material under stirring, and then get the black tape soft paint solution, take a sample on the surface of the metal sample for coating, and then quickly dry it Dry into film, filter after performance test (parameters see Table 3) is qualified, pack

[0040] table 3

[0041]

[0042]

Embodiment 3

[0044] Weigh 53.1 grams of rutile titanium dioxide powder, 12.4 grams of organic medium yellow powder, 9 grams of 3602 iron red powder, 32.3 grams of oxidized castor oil, 0.15 grams of organic bentonite, 0.08 grams of BYK-ATU, 1.27 grams of xylene, stir well, and then use three rollers to The pulp is milled to a fineness of less than 15 μm to form a color paste for later use. 107 grams of butyl acetate, 40.1 grams of ethyl acetate, 80.3 grams of butanol, 53.5 grams of acetone, 53.5 grams of ethanol, 334.4 grams of toluene, 47.7 grams of 15″ (12.2%) nitrocellulose, 77.7 grams of 120″ (12.2%) Nitrocellulose, 40.2 grams of oxidized castor oil, and 57.3 grams of 349 alkyd resin are put into the paint mixing tank, mix evenly, and slowly add the ground color paste into the above-mentioned premixed container under stirring to obtain a flesh-colored measuring tape Soft paint solution, sampled and coated on the surface of the metal sample, then quickly dried to form a film, filtered an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com