A kind of deodorization method of cod protein enzymatic hydrolyzate

A technology of protease hydrolyzate and cod, applied in the field of aquatic product processing, can solve the problems of reagent residue, low efficiency, yeast powder odor, etc., and achieve the effect of good application prospect and promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

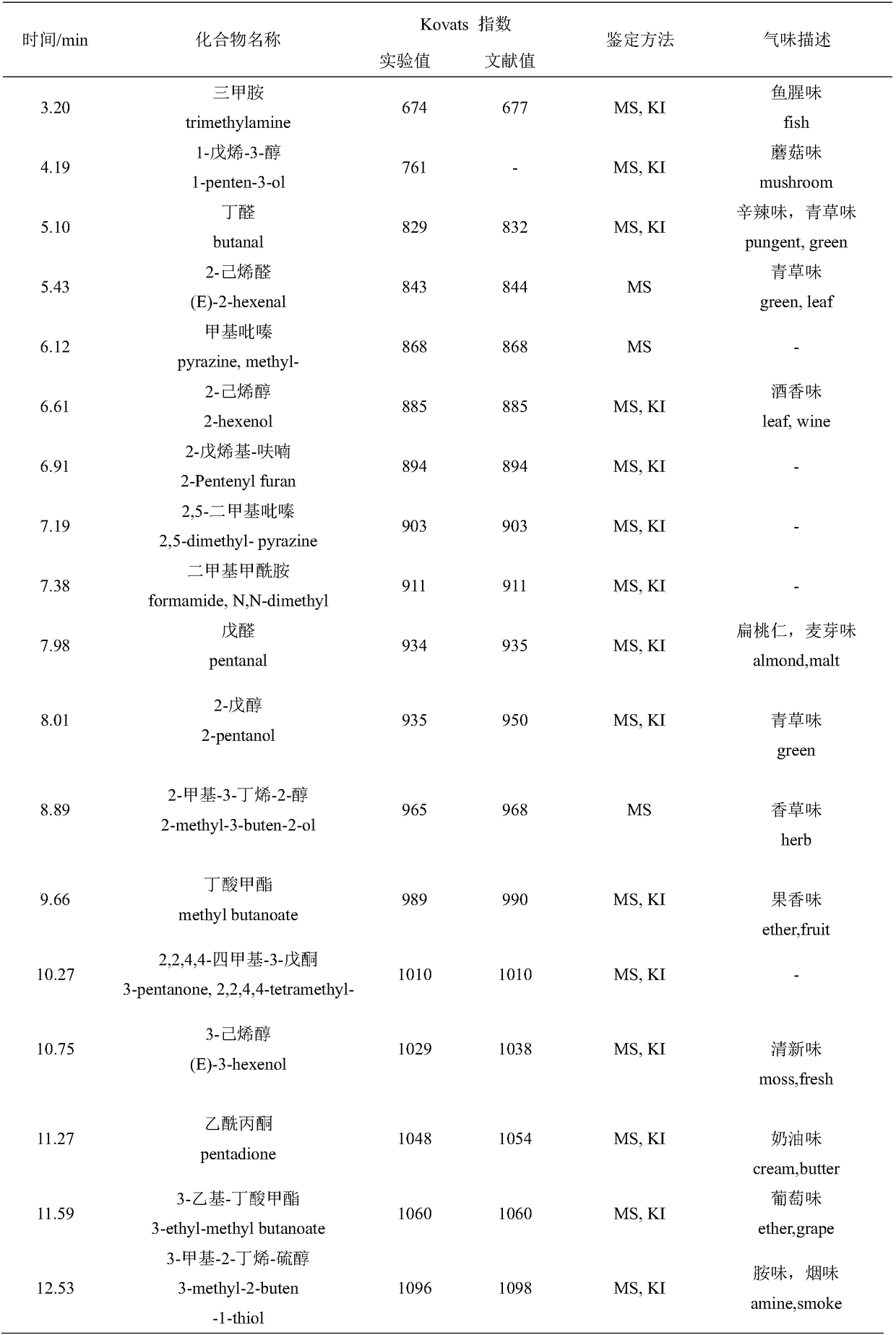

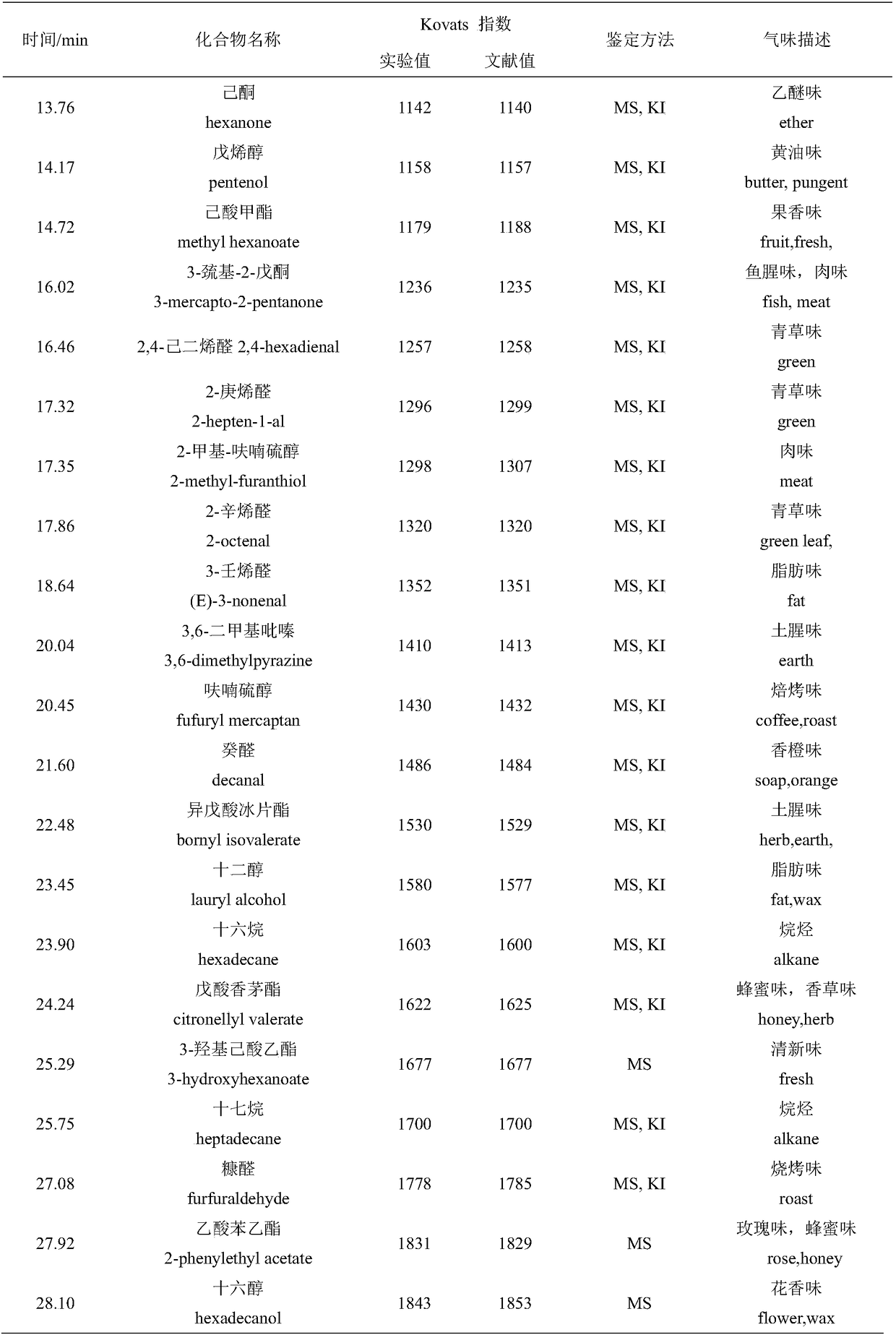

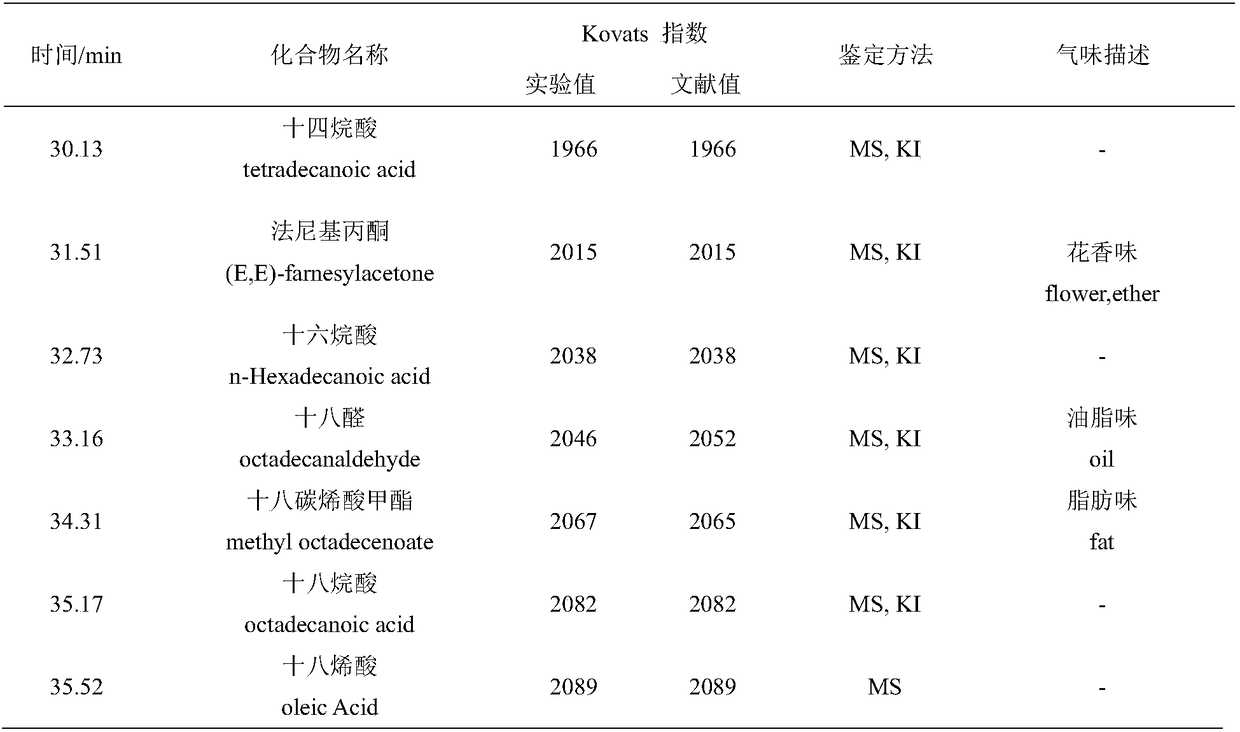

Image

Examples

Embodiment 1

[0019] The deodorization treatment of cod protein enzymatic hydrolyzate by high-voltage pulsed electric field comprises the following steps:

[0020] Purchase fresh cod, slaughter it, remove the skin and viscera, take the back fish, and use a tissue grinder to pound it into minced meat. Configure a phosphate buffer solution with a pH of 8 (take 5.59g of dipotassium hydrogen phosphate and 0.41g of potassium dihydrogen phosphate, dissolve and set the volume to 1000ml, and then add cod minced meat to phosphate buffer with 20% substrate concentration In the solution, Bacillus subtilis alkaline protease was used as a tool enzyme, and the amount of enzyme added was 0.15%, added to the buffer solution, and stirred and enzymolyzed in a water bath at 55° C. for 4 hours. After the enzymolysis is completed, the enzymolysis solution is subjected to boiling water bath to inactivate the enzyme for 10 minutes. After the enzyme-inactivated enzymatic hydrolyzate was cooled, it was centrifuged...

Embodiment 2

[0034] For fresh cod, take the back fish and pound it into minced meat with a tissue grinder. Add cod meat mince at 20% as substrate concentration to phosphate buffer solution with pH=8, use Bacillus subtilisin alkaline protease as tool enzyme, add enzyme amount 0.15%, stir and enzymolyze in 55°C water bath for 4h. After the enzymolysis is completed, the enzymolysis solution is subjected to boiling water bath to inactivate the enzyme for 10 minutes. After cooling the enzymatic hydrolyzate after deactivation, it was centrifuged at 3500r / min for 10min, and the supernatant was taken for suction filtration.

[0035] Dilute cod protein enzymatic hydrolyzate by 15 times until the peptide content is about 2 mg / mL, the conductivity is less than 2000 μS / cm, and the viscosity is close to that of water, so that the diluted cod protein enzymatic hydrolyzate meets the requirements of high-voltage pulsed electric field for samples.

[0036] Before using high-voltage pulsed electric field e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com