Manufacturing method of stainless steel foil and obtained stainless steel foil and steel-plastic film

A technology of stainless steel foil and production method, which is applied in the direction of electrical components, circuits, battery boxes/cover materials, etc., can solve the problems of insufficient surface roughness of stainless steel, difficulty in achieving the use effect, insufficient bonding strength, etc., and achieve improved resistance to electrolyte ability, avoiding material confusion, and uniform distribution of cohesive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A method for making stainless steel foil, comprising the following steps in sequence:

[0029] First, use low-temperature plasma to clean the surface of the stainless steel foil to remove oil stains on the surface of the stainless steel foil. When cleaning the surface of the stainless steel foil, the cleaning machine uses a power of 450-550W and a current of 1.5-2.2A. By using low-temperature plasma for cleaning, the phenomenon of hydrogen embrittlement caused by the traditional pickling and degreasing process on stainless steel foil is avoided. At the same time, through low-temperature plasma surface treatment, a variety of oxygen-containing groups are introduced into the surface of stainless steel foil, which changes the surface from non-polar and difficult to stick to polar, easy to stick and hydrophilic, which is conducive to bonding and coated.

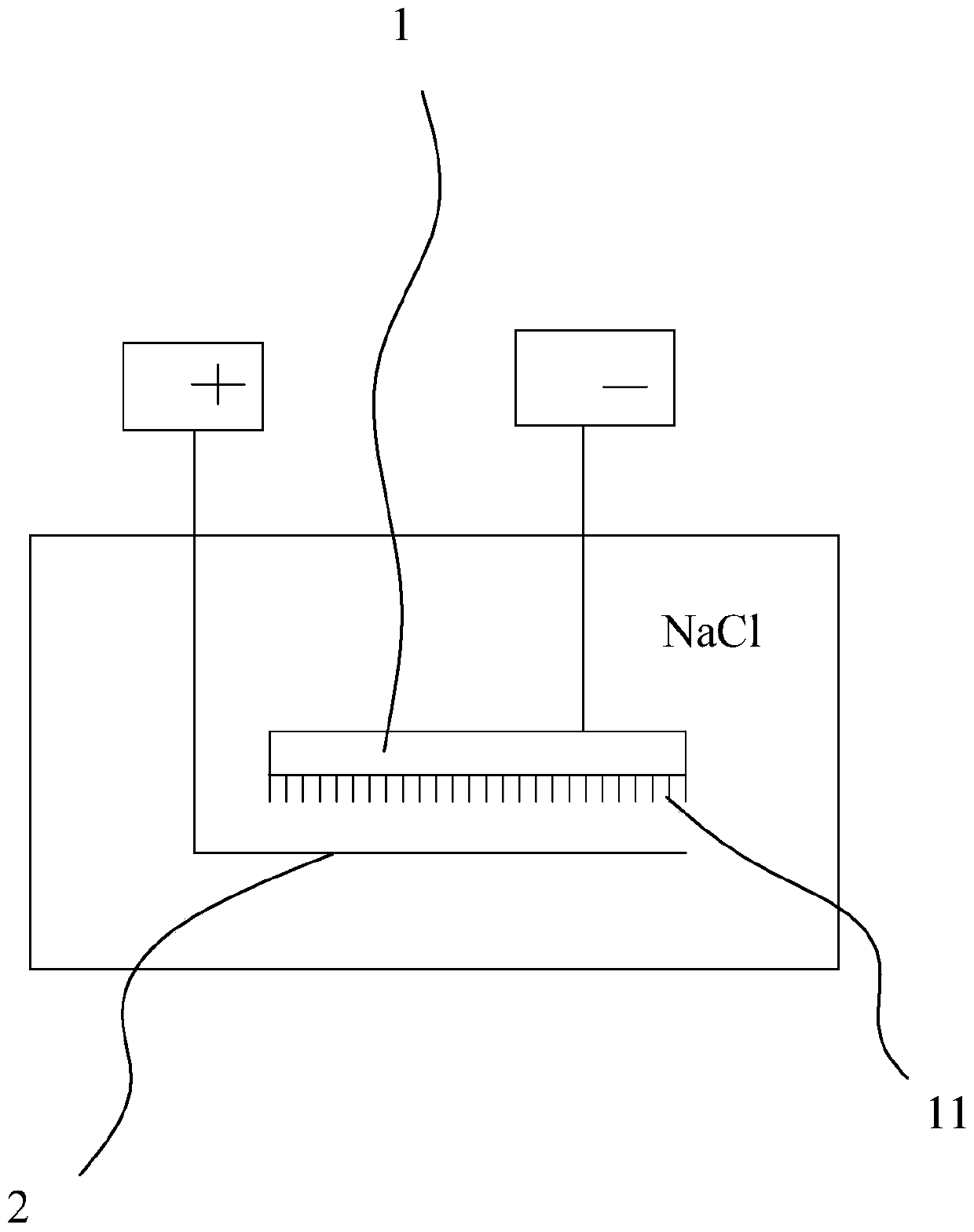

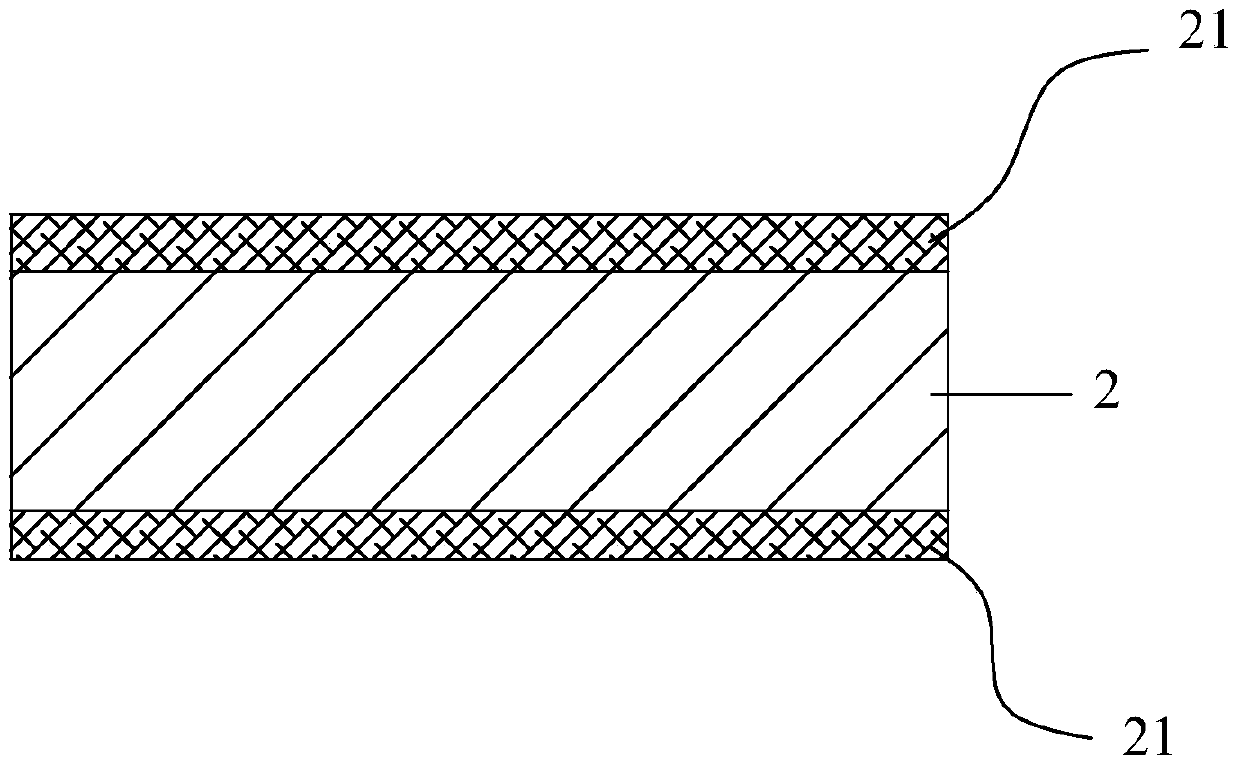

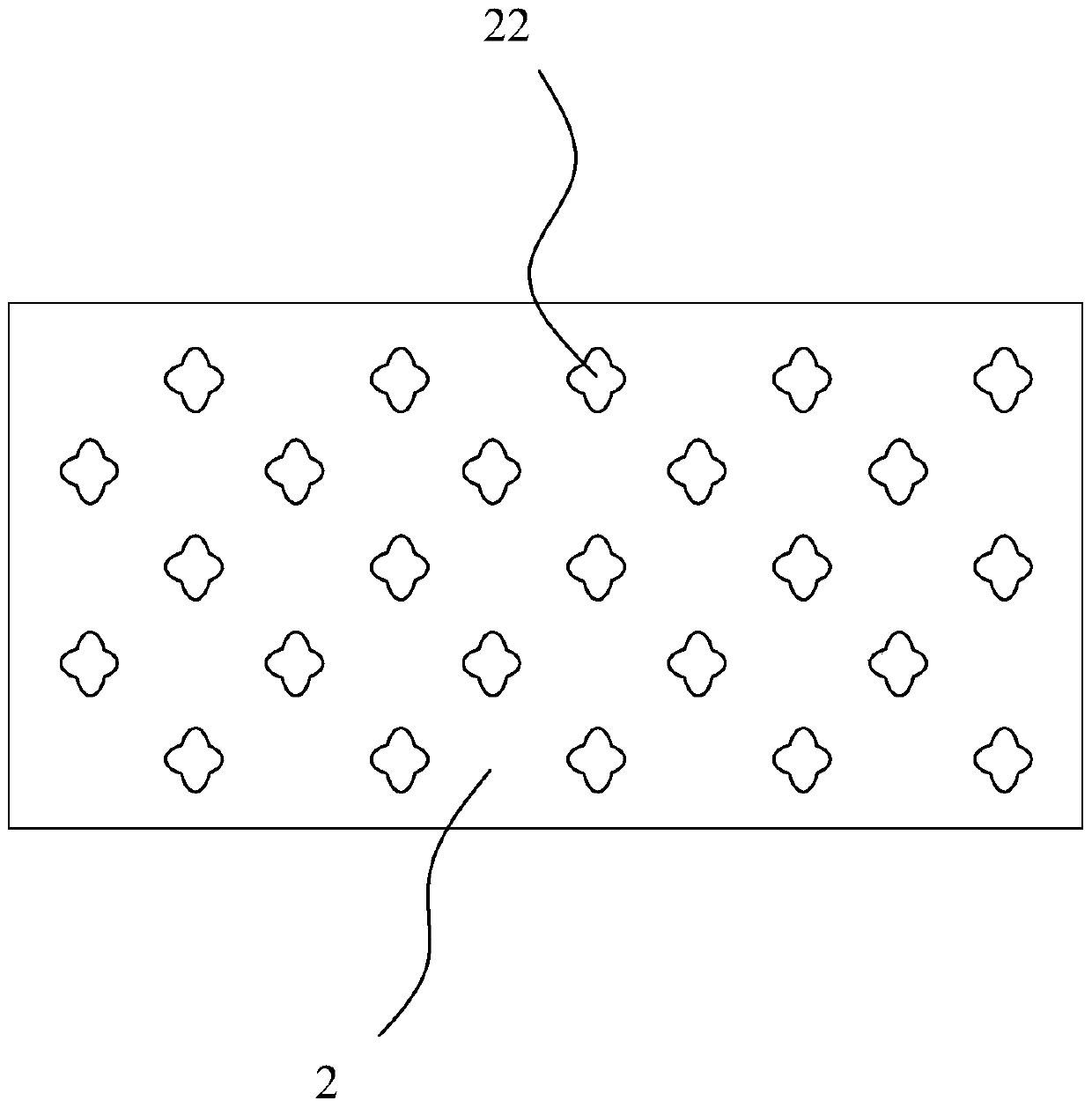

[0030] Such as Figure 1 to Figure 3 As shown, after the oil stain on the surface of the stainless steel foil is remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com