Method for measuring thickness of RTV coating of insulator

A technology of coating thickness and measurement method, which is applied in the field of measurement of RTV coating thickness of insulators, and can solve problems such as difficulty in guaranteeing application accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for measuring the thickness of an insulator RTV coating, comprising the steps of:

[0034] S1. Determine the components of the RTV paint to be tested. The ratio of organic components and fillers in the silicone rubber in the RTV coating can be measured by thermogravimetric, infrared and other methods.

[0035] S2. Take a number of transparent glass sheets numbered ① to ⑨, keep the surface clean and dry; spray the RTV paint in S1 on the glass sheet, control the thickness of the ① coating to 0.1mm, and the thickness of the ⑨ coating to 0.50 mm, the thickness interval between two adjacent coatings is 0.05mm, and the thickness of the coating is recorded as f(x i ).

[0036] S3. The parameters of the laser are nanosecond level, Nd:YAG pulsed laser, the wavelength is 1064nm, the defocus amount is -100mm~+100mm, and the energy is 50-200mJ.

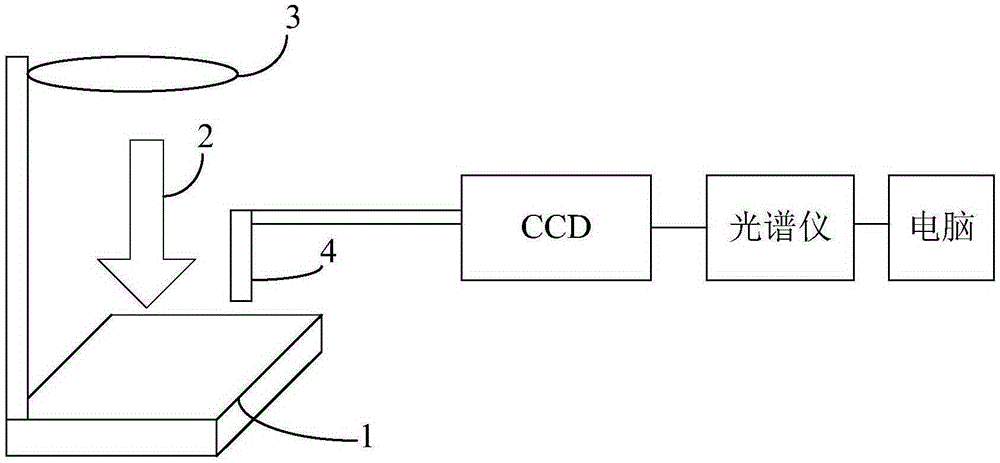

[0037] S4. Place glass pieces ① to ⑨ coated with RTV paint under the lens of the laser respectively. Adjust the lens setting...

Embodiment 2

[0043] S1. Select an RTV coating, and use a pulsed laser with specific parameters (laser parameters can refer to Example 1) to continuously bombard a point of the RTV coating, so that a hole with increasing depth is formed at the point.

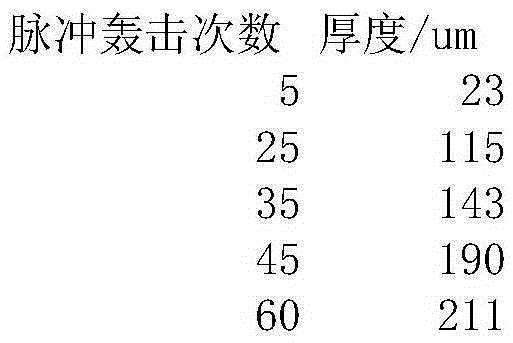

[0044] S2. Record the number of pulsed laser bombardments and the corresponding breakdown thickness of the RTV coating (that is, the disappearance thickness of the RTV coating) as shown in the following table:

[0045]

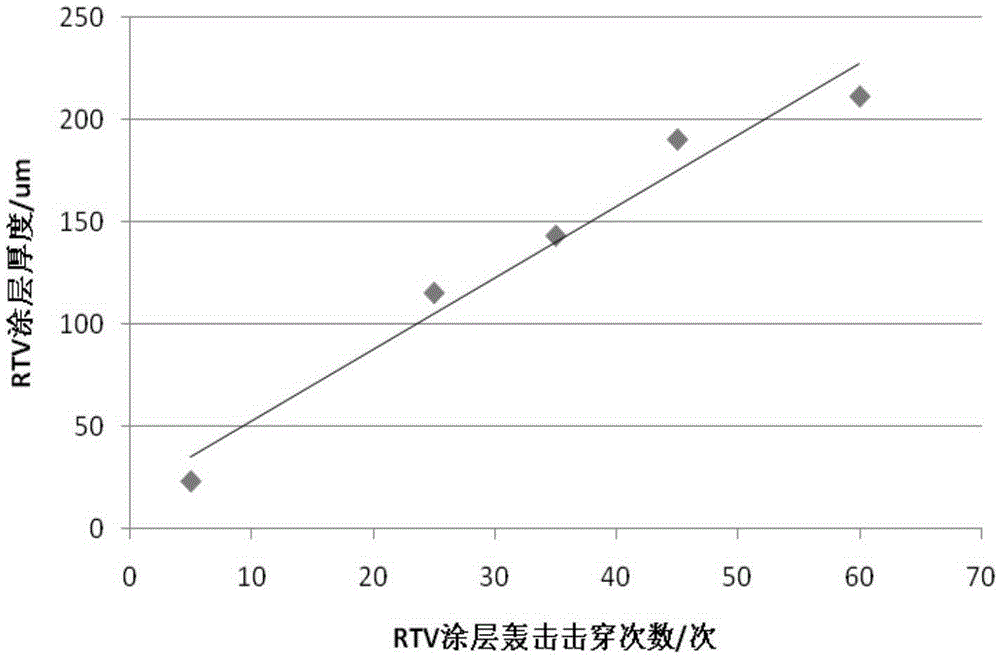

[0046] According to the above table, points are drawn on the RTV coating bombardment breakdown times-RTV coating thickness coordinates, and then curve fitting is performed on these points to obtain:

[0047] y=3.4983x+17.459.

[0048] S3. When it is necessary to measure the RTV coating of the same material, it is only necessary to measure the number of times when the pulsed laser bombardment of the same parameters penetrates the RTV coating. According to the above formula f(x)=ax+b, the type can be calculated. The thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com