Environment-friendly battery for water injection electric power generation and positive electrode and battery pack thereof

A positive electrode and battery technology, applied in the field of disposable batteries, can solve the problems of slow discharge rate, low voltage and short service life, and achieve the effects of high discharge rate, stable discharge and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

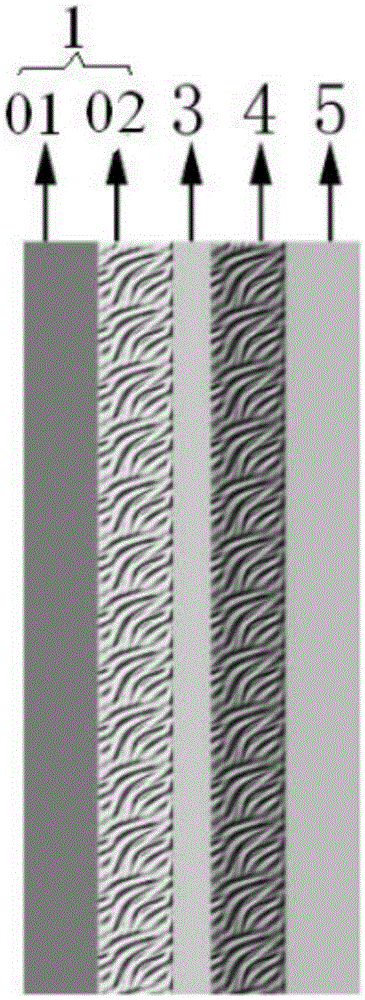

[0025] Correspondingly, on the basis of the above-mentioned positive electrode for a water-injected power generation battery, the embodiment of the present invention also provides the above-mentioned positive electrode preparation method. combined with figure 1 , the method includes the following steps:

[0026] Step S01: dispersing the soluble copper salt in polymer melt and / or solvent to prepare slurry;

[0027] Step S02: Adsorb the slurry on the first water-absorbing material base layer.

[0028] Specifically, the soluble copper salt in step S01 and the first water-absorbing material-based layer in step S02 are as described above in the positive electrode 1 , and will not be repeated here to save space.

[0029]In the above step S01, in one embodiment, when the soluble copper salt is dispersed in the polymer melt, the mass ratio of the soluble copper salt to the polymer is controlled to be (0.5-4):1. By controlling the ratio between the two, a stable slurry can be formed...

Embodiment 1

[0053] A water injection power generation battery, its structure is as follows figure 1 As shown, the battery core that includes the order of positive electrode current collector 11-positive electrode active material layer 12-semipermeable diaphragm layer 2-salt bridge layer 3-negative electrode 4 is closely attached layer by layer, wherein the positive electrode current collector 11, positive electrode The active material layers 12 together constitute the positive electrode 1 . The battery core is installed in the cavity of the battery casing.

[0054] The water injection power generation battery is prepared according to the following method:

[0055] S11. Preparation of positive electrode 1:

[0056] Take a copper sheet with a thickness of 0.5mm, cut it into a rectangle of 3cm*5cm, clean the surface of the copper sheet with ethanol, and dry it as the positive electrode current collector 11 for subsequent use;

[0057] Weigh 1g of polyethylene glycol 20000, heat it at 60°C...

Embodiment 2

[0067] A water injection power generation battery, its structure is as follows figure 1 As shown, the structure is the same as that of the water-injected power generation cell in Example 1.

[0068] The water injection power generation battery is prepared according to the following method:

[0069] S21. Preparation of positive electrode 1:

[0070] Take a carbon sheet with a thickness of 0.5mm, cut it into a rectangle of 3cm*5cm, clean the surface of the carbon sheet with ethanol, and dry it as the positive electrode current collector 11 for later use;

[0071] Weigh 1g of starch, add 1ml of water and stir until molten, then add 1.5g of copper chloride, stir evenly, apply the resulting molten mixture evenly on the surface of the 10cm*10cm water-absorbing cellulose layer, and then cut it into 3cm The size of *5cm is used as the positive electrode active material layer, and the three above-mentioned cellulose water-absorbing layers are stacked and compacted to increase the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com