Binding gold finger compensation method

A compensation method, finger technology, applied in the direction of electrical connection formation of printed components, electrical components, printed circuit liquid treatment, etc., can solve the problem that the effective area of welding cannot be satisfied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

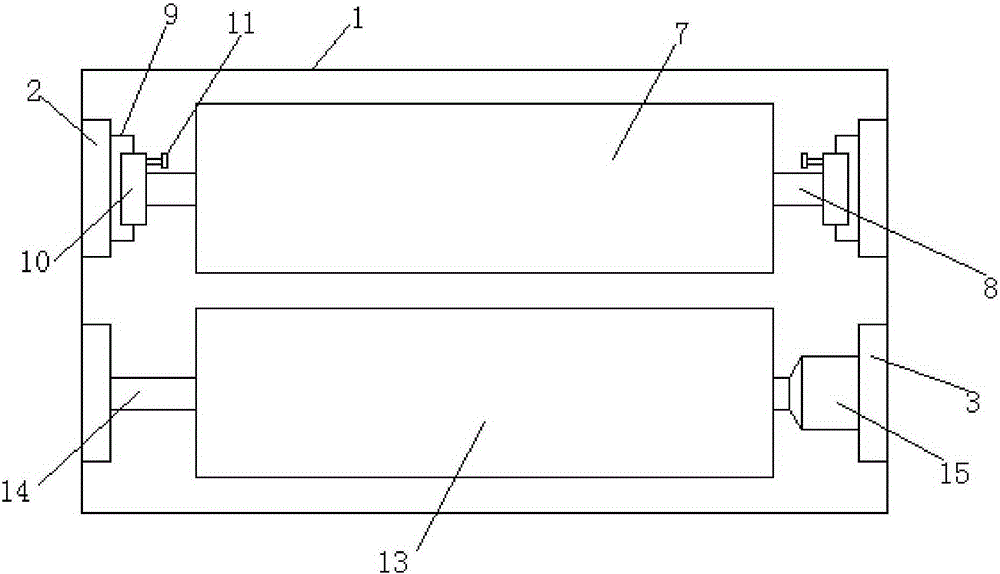

[0014] The invention provides a binding gold finger compensation method, which includes the following steps: S1: drilling, S2: copper plating, S3: dry film pretreatment, S4: pattern transfer, S5: line etching-DES, S6: AOI Inspection, S7: Printing solder mask (including pre-treatment), S8: Surface treatment, S9: Forming, S10: Electrical testing, S11: Finished product inspection-FQC.

[0015] The above-mentioned step S4: the technological process of pattern transfer is followed by dry film pressing and circuit exposure.

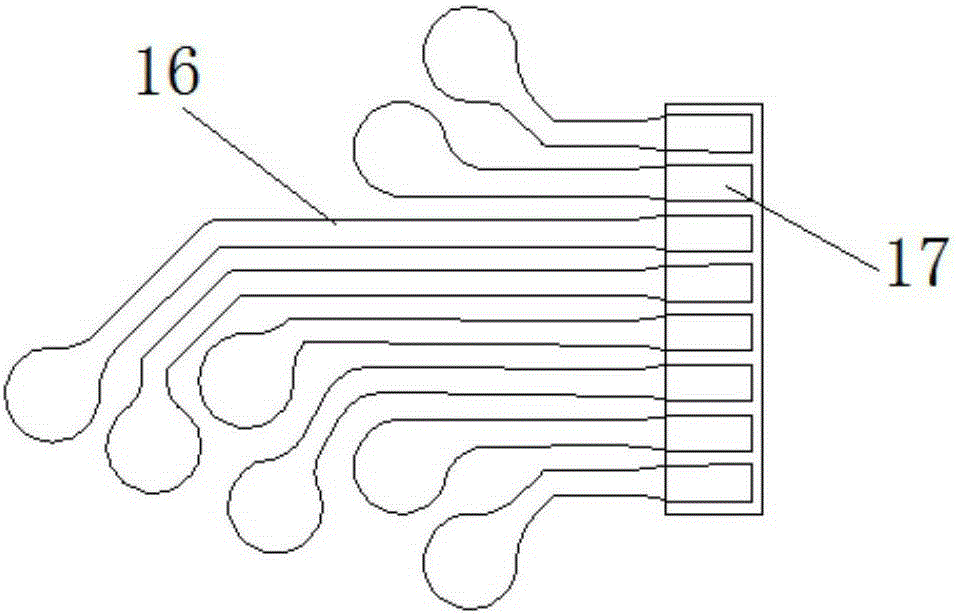

[0016] Such as figure 1 The step S5 shown: line etching-DES is to slow down the speed of liquid medicine exchange in the gap by reducing the gap between the adjacent line rear ends 17 under the premise that the line front end 16 remains unchanged, so that the etched line The rear end 17 is at a right angle, thereby ensuring that the area of the binding fingers after etching is consistent with the area of the binding fingers before etching.

[0017] The ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com