Mineral living water cup and mineral living water producing method

A water cup and running water technology, applied in the direction of drinking water utensils, etc., can solve the problems of random demand, unsatisfactory taste, and high-end requirements of users, etc., and achieve the effect of convenient replacement of functional bodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

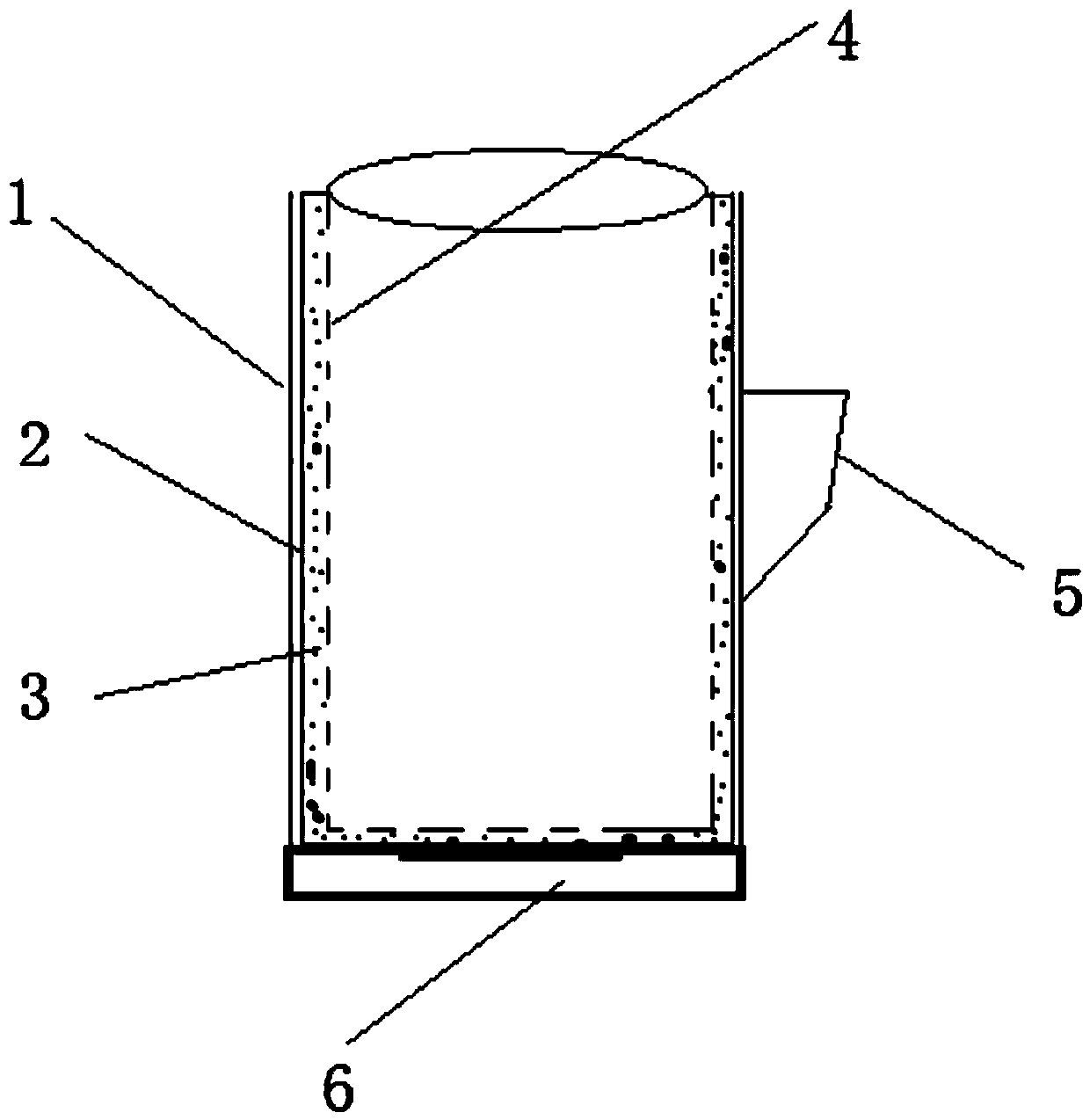

[0026] like figure 1 As shown, a mineral water cup includes a housing 1, a functional body arranged in the housing, a cup cover (not shown in the figure) and a handle 5; the outer coating layer 2 of the functional body, the inner ceramic liner 4 (the micropores on the ceramic layer in the figure are larger than the actual ones, and the actual size and distribution of the micropores are described in detail below), the nutritional composite layer 3 located between the wrapping layer 2 and the ceramic liner 4 . The nutrient complex layer 3 is made of powdery nutrient substances bonded into one body through organic glue. Nutrients in the nutritional complex layer may include silicon, selenium, calcium, magnesium, potassium, zinc, iron, cadmium and other substances that are beneficial to the human body or required by the human body and can be dissolved in water. These nutrients are formulated in appropriate proportions in advance as required. A number of micropores with a diamete...

Embodiment 2

[0031] Different from Embodiment 1, the side wall body of the housing is made of glass, and there is no handle 5. Various colors and patterns can be designed outside the wrapping layer of the functional body to make the cup more aesthetically pleasing. At the same time, it can play a role of heat insulation when soaking in boiling water, so as to further prevent hands from being scalded. Other contents are the same as those in Embodiment 1 or Embodiment 2.

Embodiment 3

[0033] Different from the first embodiment, the side wall of the casing and the wrapping layer of the functional body are combined into one, and the bottom of the cup is connected to the lower end of the functional body by bonding. The side wall body and the cup bottom of the housing are plastics. The whole mineral water cup is a one-time use cup, that is, the functional body in the cup cannot be replaced. After the nutrients in the complex nutrient layer of the functional body are used up, the cup can no longer release nutrients, but it can still be used as an ordinary cup. . The other contents are the same as the implementation one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com