Pancake Forging Forging Method

A technology of forgings and pancakes, applied in the direction of metal processing equipment, etc., can solve the problems of astonishing economic loss and high scrap rate, and achieve the effects of improving design efficiency, improving mechanical properties, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

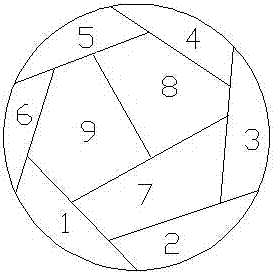

Image

Examples

Embodiment 1

[0034] An existing forging is made of 20MnMoNb ingot type of 30 tons, and the size of the formed forging is φ1875mm×245 mm. First, determine the shape of the rotary upsetting forging by Deform computer simulation. The reduction amount is 18-20%, and the anvil width ratio is 0.6-0.7; the forging process of this forging is divided into 4 fires, and the operation content of each fire is as follows :

[0035] For the first fire, heat the forgings to 1200℃ and release them, pressing and chamfering;

[0036] For the second fire, return the forging to the furnace and heat it to 1200°C and then take it out. Transfer to the forging upsetting to φ=1900mm, then draw the square to 950mm×950mm, chamfer and round to φ=950mm; cut the tail Cutting diameter φ=950mm height H=960mm;

[0037] For the third fire, return the forging to the furnace and heat it to 1200℃, then transfer it to the forging platform, first upset it on the forging platform to φ=1360mm, H=480mm, and then transfer to the rotary f...

Embodiment 2

[0040] The existing forging material is 30Cr2NiMo, the ingot type is 60 tons, and the size of the forming forging is φ2780mm×350mm. First, determine the shape of the rotary upsetting forging by Deform computer simulation. The reduction amount is 18-20%, and the anvil width ratio is 0.6-0.7; the forging process of this forging needs to be carried out in 5 fires, and the operation content of each fire as follows:

[0041] For the first fire, heat the forgings to 1200℃ and release them, pressing and chamfering;

[0042] For the second fire, return the forgings to the furnace and heat them to 1200°C and then take them out, then transfer to the forging and upsetting to φ=2100mm, then draw the square to 1200mm×1200mm, and chamfer and round to φ=1200mm; cut the tail Cutting diameter φ=1200mm height H=2050mm;

[0043] For the third fire, return the forging to the furnace and heat it to 1200℃, then transfer to the forging platform, first upset the forging platform to φ=1900mm, H=800mm, and ...

Embodiment 3

[0047] The existing forging material is 20Mn, the ingot type is 8 tons, and the size of the formed forging is φ1020mm×210mm. First, determine the shape of the rotary upsetting forging by Deform computer simulation. The reduction amount is 18-20%, and the anvil width ratio is 0.6-0.7; the forging process of this forging is divided into 4 fires, and the operation content of each fire is as follows :

[0048] For the first fire, heat the forgings to 1200℃ and release them, pressing and chamfering;

[0049] For the second fire, return the forgings to the furnace and heat them to 1200°C and then take them out, then transfer to the forging upsetting to φ=1100mm, then draw the square to 550mm×550mm, and chamfer and round to φ=550mm; cut the tail Cutting diameter φ=550mm height H=850mm;

[0050] For the third fire, return the forgings to the furnace and heat them to 1200℃, then transfer to the forging platform, first upset the forging platform to φ=800mm, H=400mm, and then transfer to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com