Process for quickly manufacturing electric power fittings based on 3D printing technology

A technology of 3D printing and power fittings, applied in manufacturing tools, metal processing equipment, casting and molding equipment, etc., can solve the problems that maintenance cannot be carried out as soon as possible, delayed power recovery time, short production time, insufficient strength, etc., to save warehouse land, The effect of short production time and convenient bonding and combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

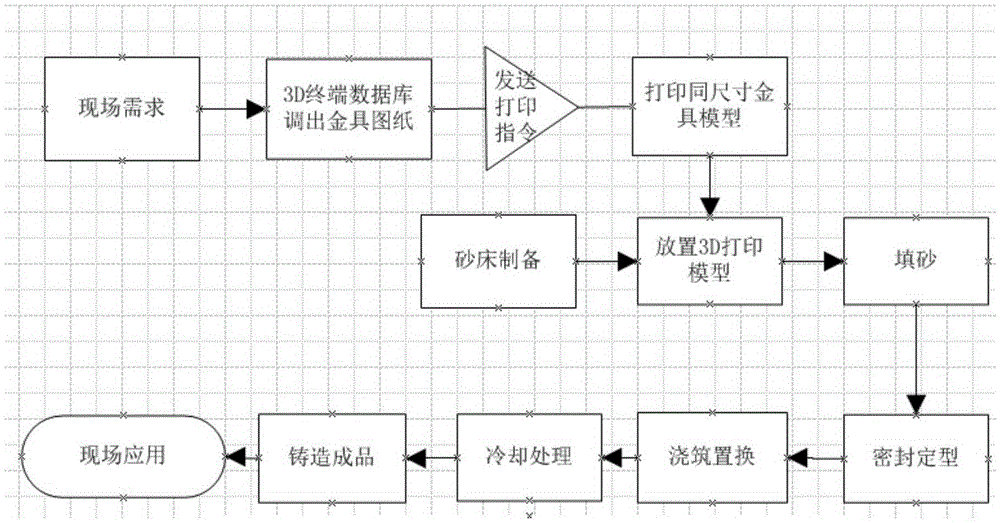

[0015] A process for quickly producing electric fittings based on 3D printing technology, including the following steps: establishing a drawing and printing program for plastic fittings samples, forming a 3D printing terminal database for plastic metal samples; 3D printing out plastic sample models; specifically, this process Based on mature non-metallic 3D printing technology, independently research the drawing and printing procedures of plastic fittings samples, form a 3D printing terminal database, call out the required fittings model drawings in real time according to on-site needs, and use 3D printing technology quickly and simply by sending printing instructions The sample mold that meets the requirements of the metalware factory can be accurately produced; because the 3D printing mold itself has a certain hardness and precision, it is unnecessary to coat a layer of paint with a certain thickness on the surface of the mold in the traditional process to form the inner shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com