Cooling structure with baffling function for inner loop surface of continuous casting crystallizer

A technology of continuous casting crystallizer and cooling structure, which is applied in the field of continuous casting crystallizer with baffled cooling structure and continuous casting and rolling production equipment. Complete contact of the hot surface, unsatisfactory heat transfer during the cooling process, etc., to achieve the effect of ensuring consistency, prolonging the residence time, and ensuring cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

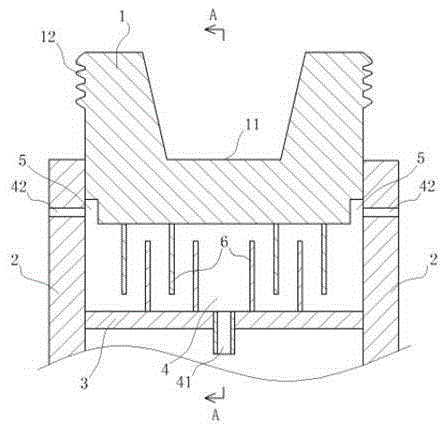

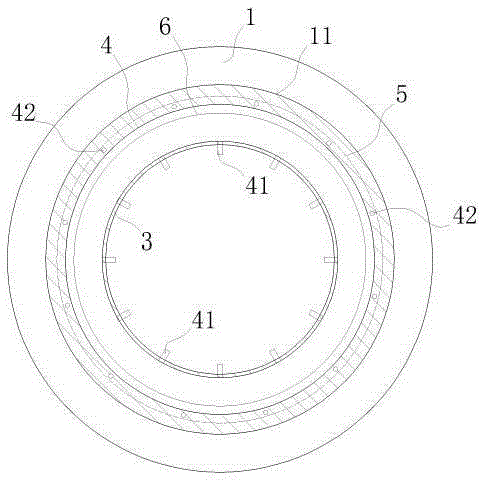

[0027] The inner ring surface of the continuous casting crystallizer of the present invention has a baffled cooling structure, and its structure is as follows: figure 1 As shown, it includes a crystallization wheel body 1 and a casting groove 11 arranged on the outer peripheral wall of the crystallization wheel body 1. The crystallization wheel body 1 is assembled between two turntables 2, and there is also a ring-shaped ring between the two turntables 2. Horizontal plate 3, said horizontal plate 3 is located at the inner side of the ring of crystallization wheel body 1; said crystallization wheel body 1, turntable 2 and horizontal plate 3 form a main cavity 4 for cooling liquid circulation, said crystallization wheel There is a ring cavity 5 between both sides of the wheel body 1 and the assembly surface of the turntable 2, and the ring cavity 5 is connected to the main cavity 4; the middle position of the width of the horizontal plate 3 is provided with an inlet 41 for coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com