General assembly production line for remote controllers

A remote control and production line technology, applied in the field of assembly equipment, can solve the problems of low production efficiency, technical influence of assembly workers, and high labor intensity, and achieve the effects of reducing labor intensity, improving production efficiency and output, and reducing production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to fully understand the technical content of the present invention, the technical solution of the present invention will be further introduced and illustrated below in conjunction with schematic diagrams, but is not limited thereto.

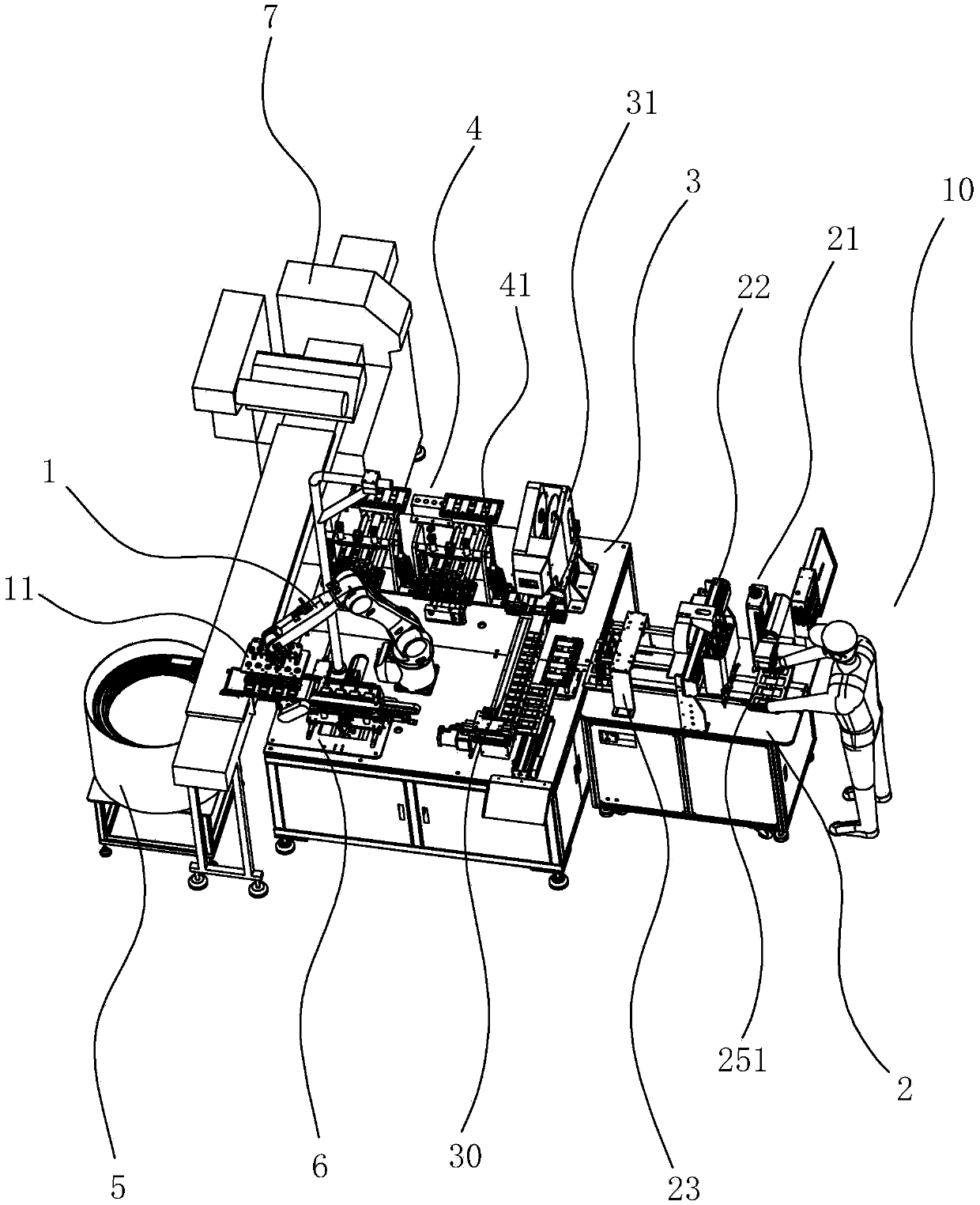

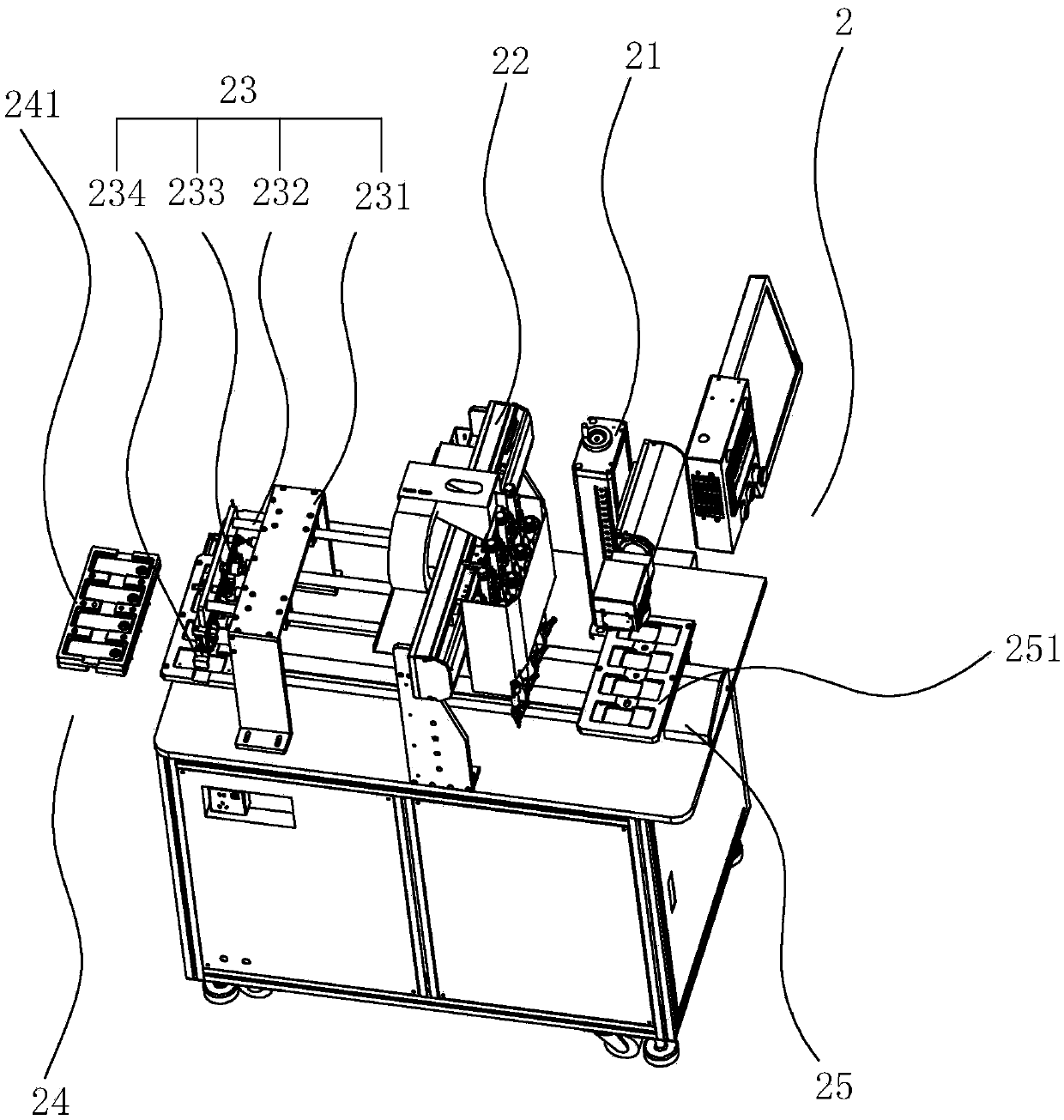

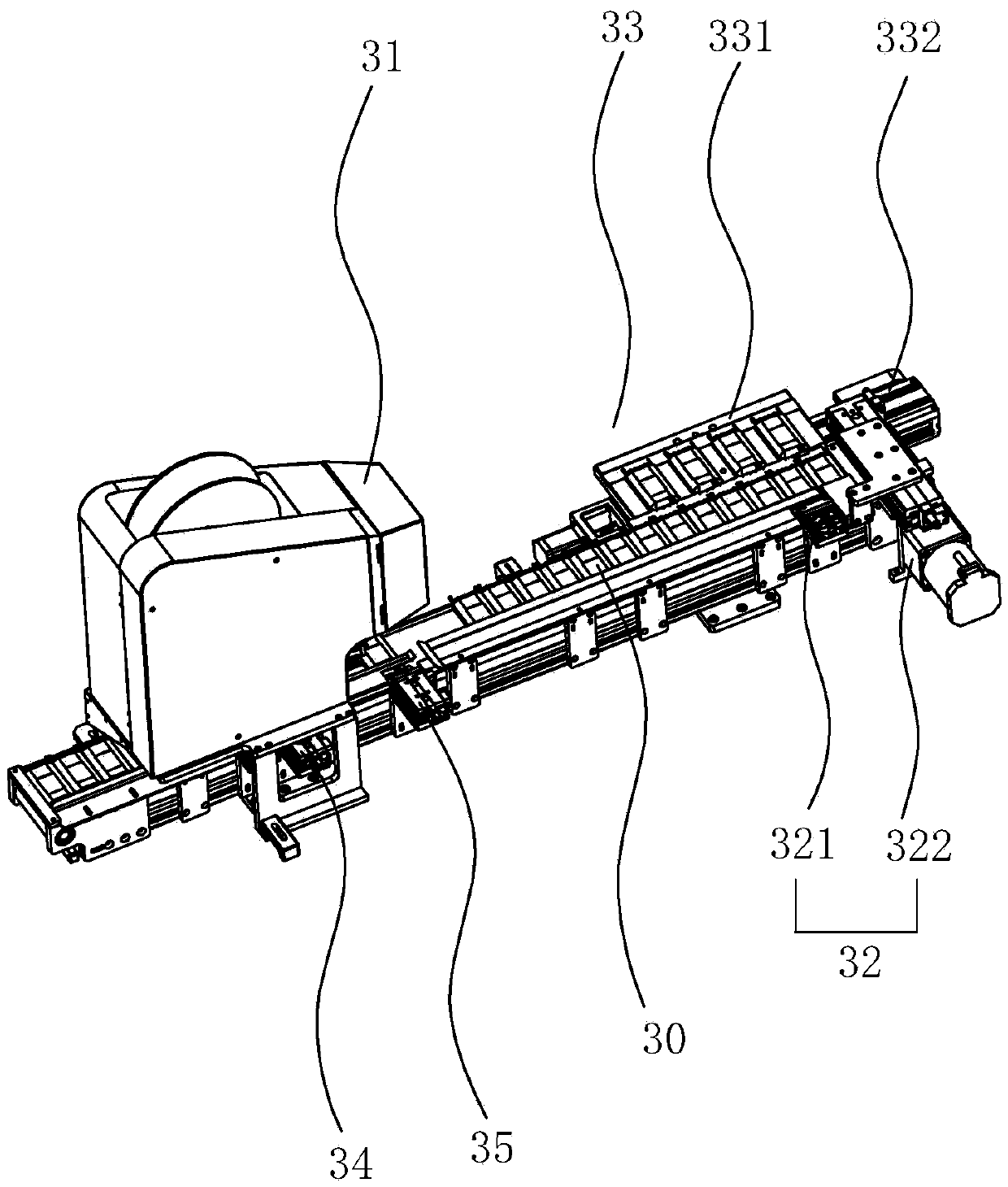

[0061] Such as figure 1 As shown, a remote control assembly line 10 includes: a retrieving robot 1 for removing remote control components, an upper shell loading platform 2 arranged on the outer periphery of the retrieving robot 1, and a bottom on the outer periphery of the retrieving robot 1 Shell loading platform 3, shell assembly platform 4 located on the periphery of reclaiming robot 1, battery cover feeding device 5 located on the periphery of retrieving robot 1, battery cover assembly platform 6 located at the end of battery cover feeding device 5, The remote control testing machine (not shown) arranged on the outer periphery of the retrieving robot 1 is arranged on the discharging transport device 7 arranged on the outer pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com