Polymer functional nonwoven fabric

A non-woven fabric and functional technology, applied in the field of polymer functional non-woven fabrics, can solve the problems of fast and efficient moisture absorption, poor antistatic effect of non-woven fabrics, and insufficient strength, so as to improve human microcirculation and prevent Itchy skin, strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

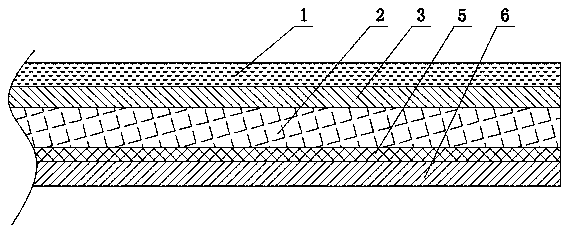

[0016] Example 1: Combination figure 1 As shown, the polymer functional non-woven fabric includes a flax fiber layer 2, an upper polypropylene layer 3 and a lower polypropylene layer 6, and the flax fiber layer 2 is located between the upper polypropylene layer 3 and the lower polypropylene layer 6. A bamboo carbon magnetic fiber layer 5 is arranged between the flax fiber layer 2 and the lower polypropylene layer 6 , and a nano-titanium dioxide photocatalyst layer 1 is also arranged on the upper polypropylene layer 3 .

[0017] Such as Figure 4 As shown, the bamboo carbon magnetic fiber layer 5 is formed by interweaving far-red polyester fibers 51, bamboo charcoal polyester fibers 52, and magnetic fibers 52. Wherein the far-red polyester fiber 51 is a warp thread, and the bamboo charcoal polyester fiber 52 and the magnetic fiber 53 are plied together to form a weft thread and warp thread to weave to form the bamboo carbon magnetic fiber layer 5 .

[0018] Manufacturing meth...

Embodiment 2

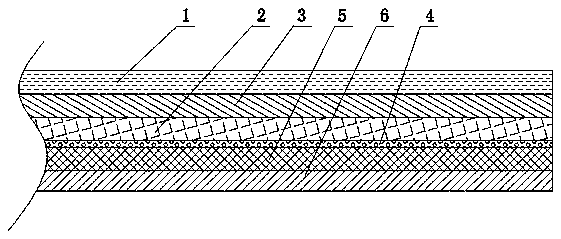

[0026] Example 2: Combining figure 2 As shown, the difference from Example 1 is that the antibacterial and antistatic high-performance nonwoven fabric is provided with a perforated aluminum film layer 4 between the flax fiber layer 2 and the bamboo carbon magnetic fiber layer 5 .

[0027] Manufacturing method: 1. Weave the bamboo carbon magnetic fiber layer 5 first, put it into the vacuum aluminum plating machine to carry out vacuum aluminum plating on the bamboo carbon magnetic fiber layer, and form through-hole aluminum with holes by accelerating the speed of aluminum delivery and reducing the current of the evaporation boat. Thin film layer 4, flax fiber layer 2 is then combined with perforated aluminum film layer 4, bamboo carbon magnetic fiber layer 5 to form gray cloth, then gray cloth is placed on the first horizontal net conveyor belt 28, so that bamboo carbon magnetic fiber layer 5 down;

[0028] 2. Polypropylene (PP) pellets are used as raw materials, melted and ex...

Embodiment 3

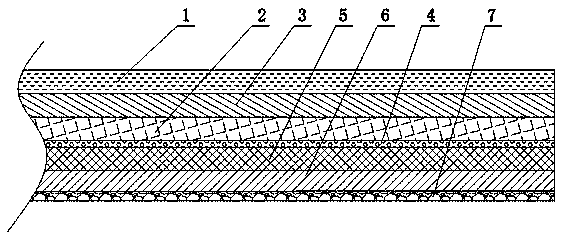

[0037] Example 3: Binding image 3 As shown, the difference from Example 1 is that a skin-friendly layer formed by blending mulberry silk and silver fiber is compounded under the lower polypropylene layer 6 .

[0038] Manufacturing method: 1. Weave the bamboo carbon magnetic fiber layer 5 first, then combine the flax fiber layer 2 and the bamboo carbon magnetic fiber layer 5 to form a gray cloth, and then put the gray cloth on the first horizontal mesh conveyor belt 28 to make the bamboo carbon magnetic The fiber layer 5 faces downward;

[0039] 2. Polypropylene (PP) pellets are used as raw materials, melted and extruded by a screw extruder at high temperature, and sprayed on the flax fiber layer 2 through the melt-blown non-woven nozzle 10 to form the upper polypropylene layer 3;

[0040] 3. The gray cloth is wound through the second horizontal mesh conveyor belt 30, so that the bamboo carbon magnetic fiber layer 5 faces upwards, and another screw extruder passes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com