Numerical control type glass plate engraving machine

A glass plate and engraving machine technology, applied in the field of engraving machines, can solve the problems of insufficient safety and reliability, low work efficiency, staff injury, etc., and achieve the effect of convenient and easy adjustment of program trajectory, stable and reliable movement accuracy, and injury avoidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

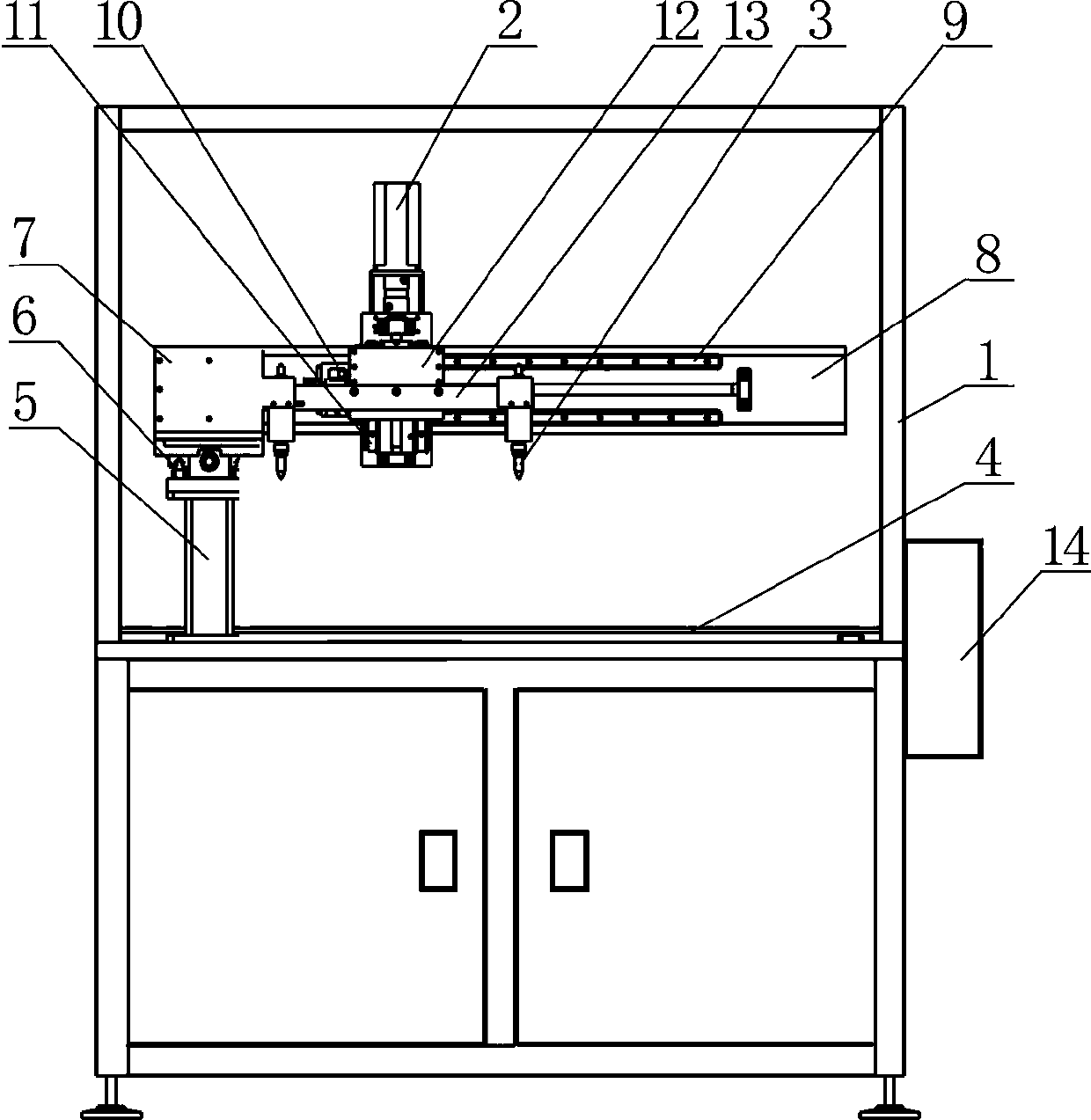

[0013] Such as figure 1 As shown, the CNC glass plate engraving machine includes an organic case 1, three motors 2, a PLC controller 14 and a carving knife 3. A horizontal partition 4 is provided in the cabinet, and a support platform 5 is provided on the horizontal partition 4. , the support platform 5 is provided with a horizontal longitudinal guide rail 6, and the horizontal longitudinal guide rail 6 is provided with a horizontal longitudinal slider 7; the horizontal longitudinal slider 7 is provided with a horizontal beam 8 perpendicular to the horizontal longitudinal guide rail 6, and one end of the horizontal beam 8 is connected to the Horizontal longitudinal slide block 7 is fixedly connected, and horizontal beam 8 is provided with horizontal transverse guide rail 9, and described horizontal transverse guide rail 9 is provided with horizontal traverse slide block 10; Horizontal traverse slide block 10 is provided with vertical guide rail 11, vertically The guide rail 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com