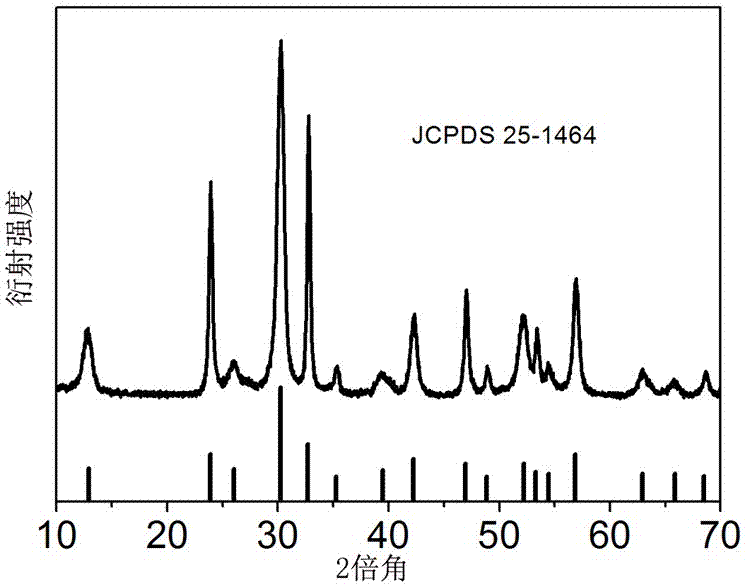

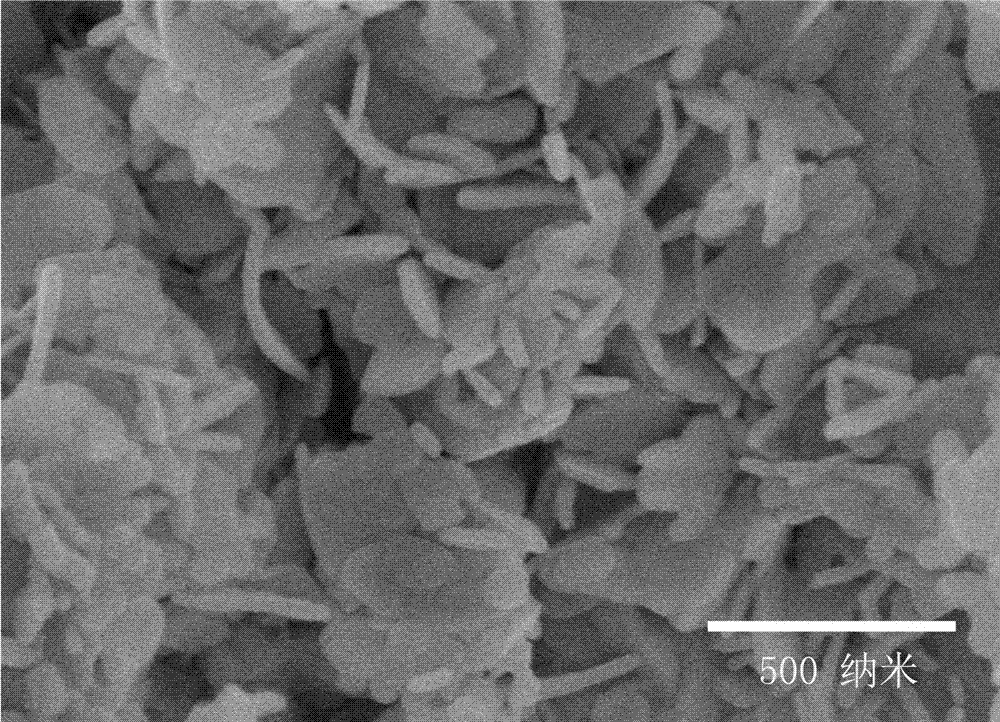

A method for synthesizing bismuth oxycarbonate nanosheets by solid phase chemical reaction at room temperature

A bismuth oxycarbonate nanometer, chemical reaction technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, inorganic chemistry, etc., can solve the problems of poor thermal stability of materials, complex synthesis process, and high reaction temperature, Achieve the effects of high product yield, simple preparation method and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Accurately weigh 0.005 mol of bismuth nitrate and grind it finely, then add 0.015 mol of sodium bicarbonate and grind it quickly. As the grinding progresses, the mixture changes from white viscous to white fine powder. Continue grinding for 40 minutes to ensure sufficient reaction The product was washed with water and ethanol, filtered with suction, and finally dried in air at room temperature for 1 hour to obtain bismuth oxycarbonate nanosheets.

Embodiment 2

[0015] Accurately weigh 0.005 mol of bismuth nitrate and grind it finely, then add 0.015 mol of ammonium carbonate and grind quickly. As the grinding progresses, the mixture changes from white viscous to white fine powder. Continue grinding for 40 minutes to ensure that the reaction is fully carried out , the product was washed with water and ethanol, filtered with suction, and finally dried in air at room temperature for 1 hour to obtain bismuth oxycarbonate nanosheets.

Embodiment 3

[0017] Accurately weigh 0.005 mol of bismuth nitrate and grind it finely, then add 0.015 mol of potassium bicarbonate and grind it quickly. As the grinding progresses, the mixture changes from white viscous to white fine powder. Continue grinding for 40 minutes to ensure sufficient reaction The product was washed with water and ethanol, filtered with suction, and finally dried in air at room temperature for 1 hour to obtain bismuth oxycarbonate nanosheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com