C30 durable recycled shaping aggregate concrete prepared from construction wastes and preparation method

A construction waste and durability technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of poor durability of recycled aggregates, low utilization rate of concrete aggregates, difficulty in recycling construction waste, etc. , to achieve the effect of material recycling guarantee, significant social and environmental benefits, and improved anti-chlorine penetration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

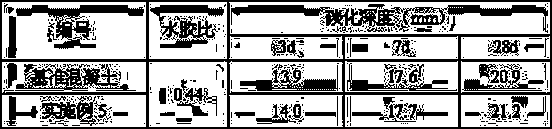

Embodiment 1

[0015] Example 1: A C30 durable recycled plastic aggregate concrete prepared from construction waste, consisting of the following raw materials: cement 280kg, fly ash 50kg, mineral powder 80kg, fine aggregate 800kg, coarse aggregate 1020kg, plus The fine aggregate is 11.5kg of water and 180kg of water. The fine aggregate is a mixture of sand and recycled plastic fine aggregate. The recycled plastic fine aggregate accounts for 20% of the total weight of the fine aggregate. The coarse aggregate is crushed stone and recycled plastic coarse aggregate. Aggregate mixing, of which recycled plastic coarse aggregate accounts for 20% of the total weight of coarse aggregate.

[0016] The fineness modulus of the recycled plastic fine aggregate is 2.9%, and the apparent density is 2480kg / m 3 , The bulk density is 1390kg / m 3 , The content of fine powder is 3%, the content of mud is 0.8%, the water demand ratio of reclaimed mortar is 1.15, the strength ratio of reclaimed mortar is 1.00; the recl...

Embodiment 2

[0018] Example 2: A C30 durable recycled plastic aggregate concrete prepared from construction waste, consisting of the following raw materials: cement 280kg, fly ash 50kg, mineral powder 80kg, fine aggregate 800kg, coarse aggregate 1020kg, plus 11.5kg of water and 180kg of water. The fine aggregate is a mixture of sand and recycled plastic fine aggregate. The recycled plastic fine aggregate accounts for 40% of the total weight of the fine aggregate. The coarse aggregate is crushed stone and recycled plastic coarse aggregate. Aggregate mixing, of which recycled plastic coarse aggregate accounts for 40% of the total weight of coarse aggregate. The other methods are the same as those described in Example 1.

Embodiment 3

[0019] Example 3: A C30 durable recycled plastic aggregate concrete prepared from construction waste, composed of the following raw materials: cement 280kg, fly ash 50kg, mineral powder 80kg, fine aggregate 800kg, coarse aggregate 1020kg, plus 11.5kg of water and 180kg of water. The fine aggregate is a mixture of sand and recycled plastic fine aggregate. The recycled plastic fine aggregate accounts for 60% of the total weight of the fine aggregate. The coarse aggregate is crushed stone and recycled plastic coarse aggregate. Aggregate mixing, of which recycled plastic coarse aggregate accounts for 60% of the total weight of coarse aggregate. The other methods are the same as those described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com