Degradable mulch film for anti-drip irrigation belt burn

A technology of degradable mulch and drip irrigation tape, which is applied in the field of soil irrigation, can solve the problems of starch-added degradable mulch film, poor stretchability and light transmittance, low strength of paper mulch or hemp mulch, and difficulty in controlling the degradation time, so as to eliminate water droplets The formation of convex mirrors, the reduction of glass transition temperature, and the effect of preventing drip irrigation tape from burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add the mixture of 34% polylactic acid, 35% polycaprolactone, 25% polyethylene glycol, 5% talcum powder, and 1% triphenyl phosphite into the high-speed mixer in the weight ratio of raw materials. The screw extruder extrudes and granulates, and blows into a film to obtain a degradable agricultural mulch film for anti-drip irrigation belt burns.

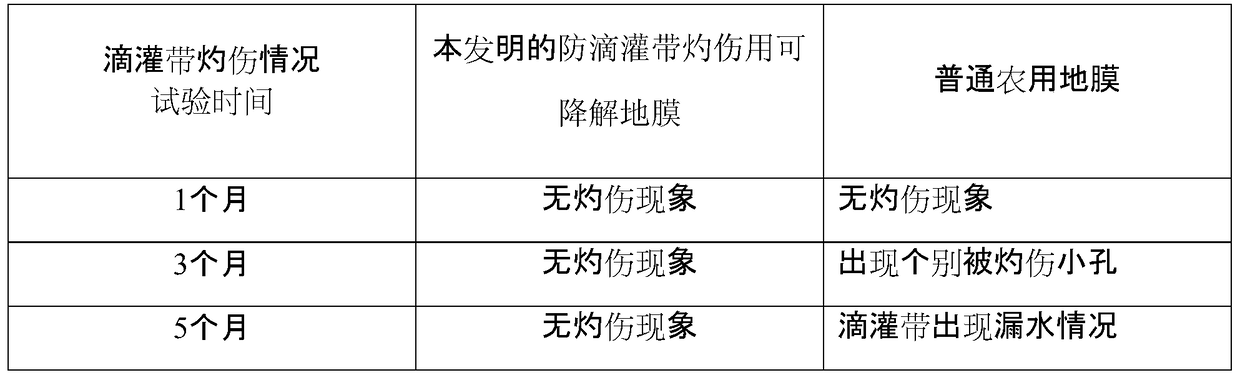

[0025] Table 1 is the comparative burning situation of the drip irrigation tape under the film.

[0026]

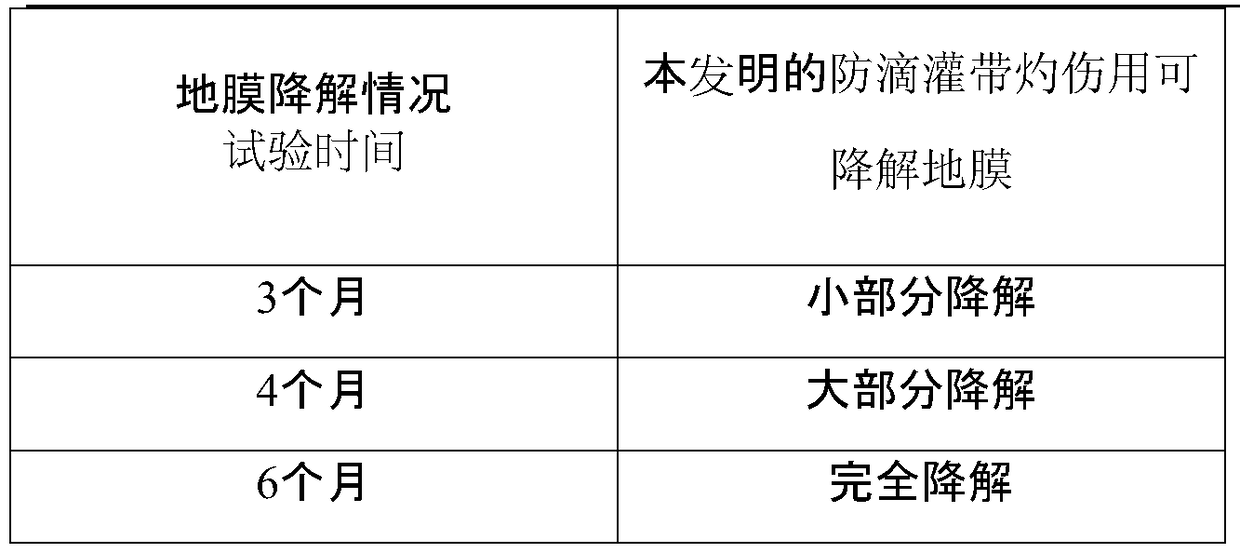

[0027] Table 2 is the degradation situation of the degradable mulch film for anti-drip irrigation belt burn of the present invention.

[0028]

[0029] Contrast the mulch film prepared by Example 1 of the present invention with the common agricultural mulch film and the drip irrigation tape to carry out drip irrigation under the film. The burn situation of the drip irrigation tape can be found in Table 1. The drip irrigation tape of the mulch film of the present invention has no burn situation, while using common The...

Embodiment 2

[0031] Add the mixture of 50% polylactic acid, 25% polycaprolactone, 15% polyethylene glycol, 8% talcum powder and 2% triphenyl phosphite in the high-speed mixer in the weight ratio of raw materials. The screw extruder extrudes and granulates, and blows into a film to obtain a degradable agricultural mulch film for anti-drip irrigation belt burns.

Embodiment 3

[0033] Add the mixture of 25% polylactic acid, 50% polycaprolactone, 15% polyethylene glycol, 9.9% talcum powder and 0.1% triphenyl phosphite into the high-speed mixer in the weight ratio of raw materials, mix well and pass through double The screw extruder extrudes and granulates, and blows into a film to obtain a degradable agricultural mulch film for anti-drip irrigation belt burns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com