Sodium-potassium alloy vacuum distillation device

A distillation device and technology of sodium-potassium alloy, which is applied in the field of sodium-potassium alloy vacuum distillation device, can solve the problem that separation equipment is difficult to apply to sodium-potassium alloy vacuum distillation separation, etc., and achieve the solution of vacuum distillation problem, good separation effect and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

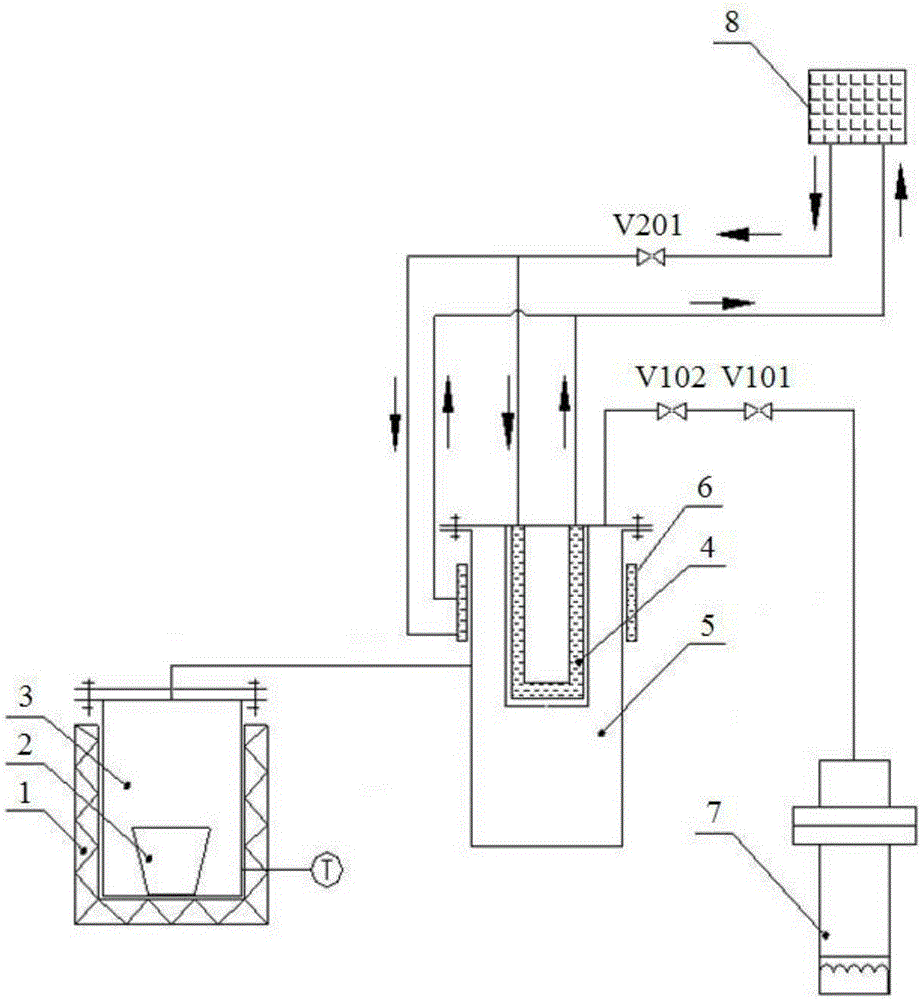

[0024] The sodium-potassium alloy vacuum distillation device of the present invention is used for vacuum distillation of a sodium-potassium alloy sample (device structure is attached figure 1 As shown), it mainly includes the following steps:

[0025] a. Connect the equipment so that the valves of the sodium-potassium alloy vacuum distillation device are closed;

[0026] b. Turn on the vacuum unit and valves V101, V102, and pump to vacuum -3 Pa; turn on the heating device and keep the vacuum, after a period of time, turn off the heating device;

[0027] c. Close the valves V101 and V102, remove the still and collection tank from V102, and transfer them to the glove box protected by inert gas;

[0028] d. Transfer the sodium-potassium alloy sample to the crucible and place it in the distillation kettle. After sealing, remove the distillation kettle and collection tank out of the glove box, and connect the vacuum unit back at V102;

[0029] e. Open the refrigeration device and valve V201...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com