A cluster tube external combustion engine

A cluster tube and engine technology, which is used in machines/engines, hot gas variable capacity engine devices, mechanical equipment, etc., can solve the problems of limited thermal energy utilization efficiency and heat loss, and achieve simple structure, reduce thermal energy consumption, and thermal energy utilization rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

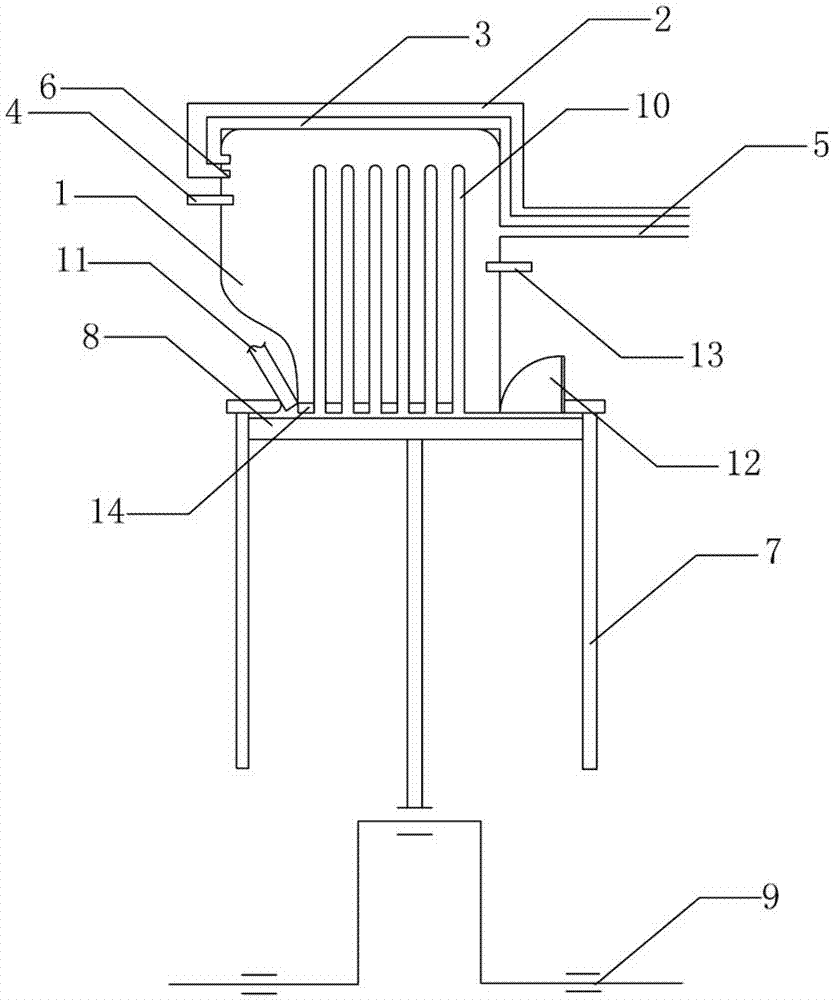

[0031] Such as figure 1 As shown, a cluster tube external combustion engine has a combustion system and a power conversion device. The combustion system includes a combustion chamber 1, a fuel pipe 2 connected to the combustion chamber 1, an intake pipe 3, an igniter 4, an exhaust passage 5, The fuel injector 6 connected to the end of the fuel pipe 2, the power conversion device includes a cylinder 7, a piston 8 arranged in the cylinder 7, a crankshaft 9 connected to the lower end of the piston 8, and the lower end of the combustion chamber 1 is connected to the upper end of the cylinder 7 A partition wall 14 is provided between the combustion chamber 1 and the cylinder 7. The top of the cluster tube 10 is sealed and the bottom is open. Exhaust valve 12.

[0032] The diameter of the cylinder 7 is 90mm, the stroke of the piston 8 is 100mm, the ratio of the cavity in the bundle tube 10 to the volume of the cylinder 7 is 1:20, and the bundle tube 10 uses 3103# stainless steel se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com