Device for real-time automatic measurement of runoff mud and sand and measurement method

A measuring device and automatic measurement technology, which is applied in the direction of measuring device, measuring flow/mass flow, liquid/fluid solid measurement, etc., can solve the problem of real-time automatic and accurate measurement of runoff and sediment, so as to reduce labor cost and ensure accuracy performance, enhancing the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

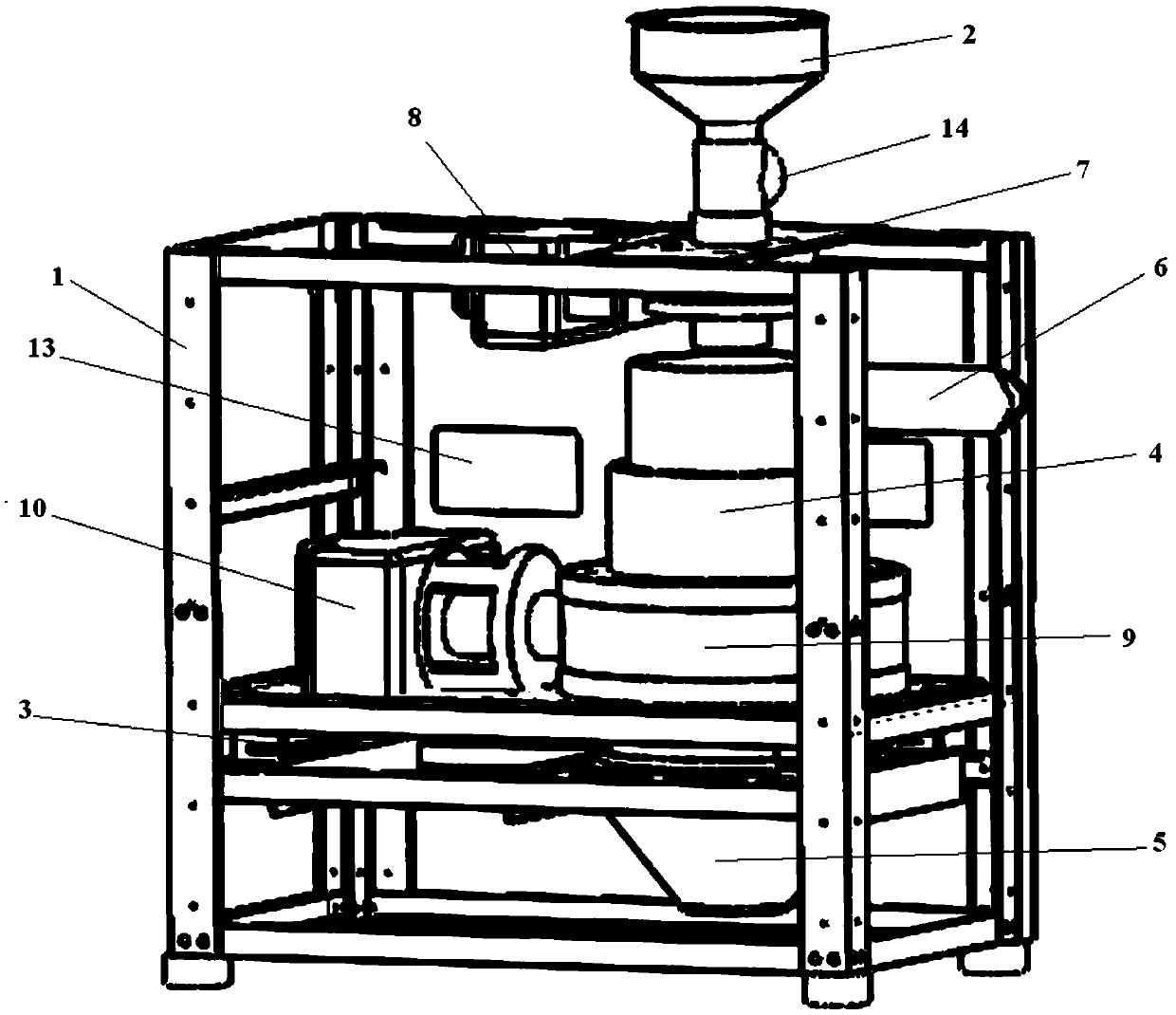

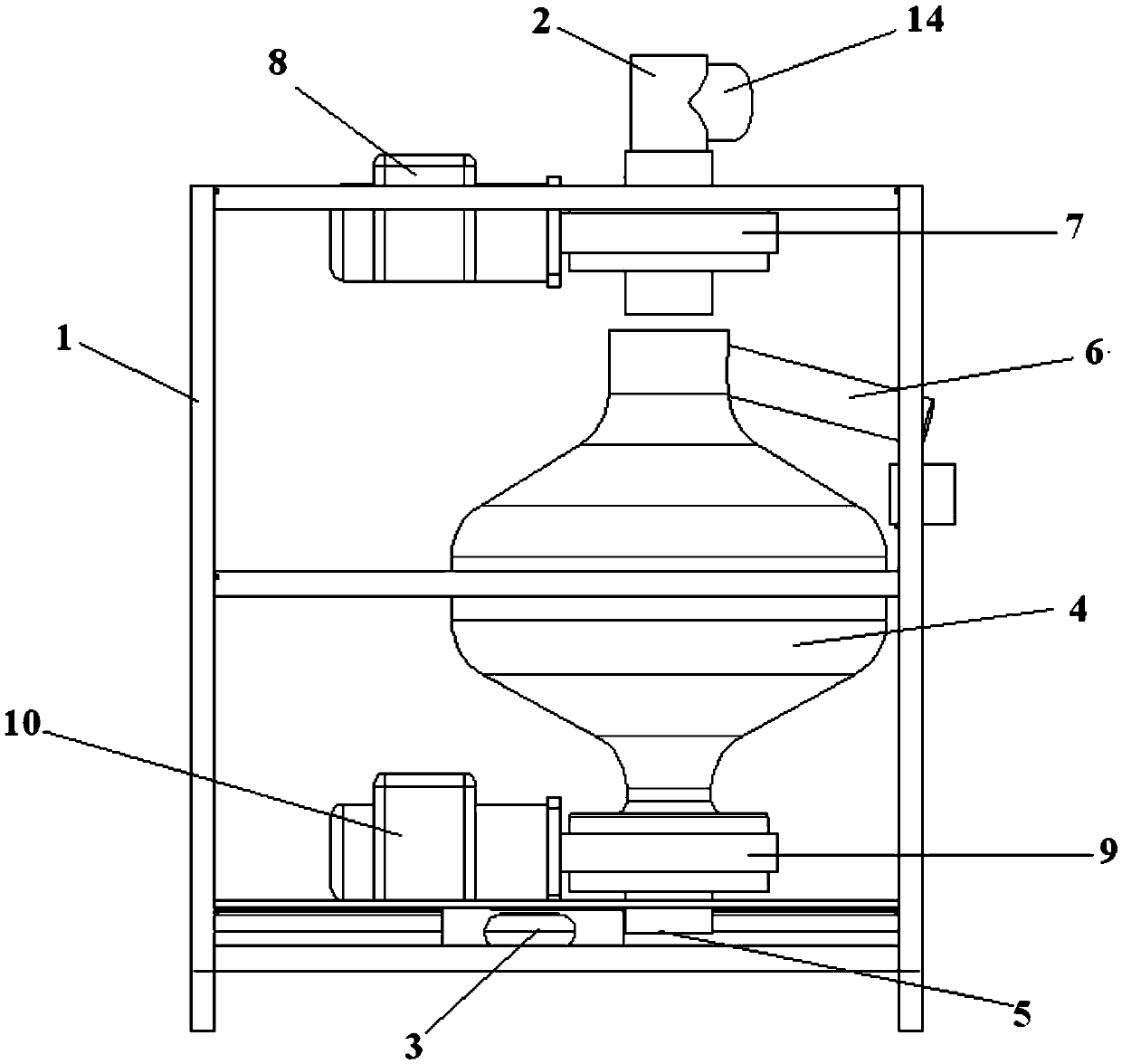

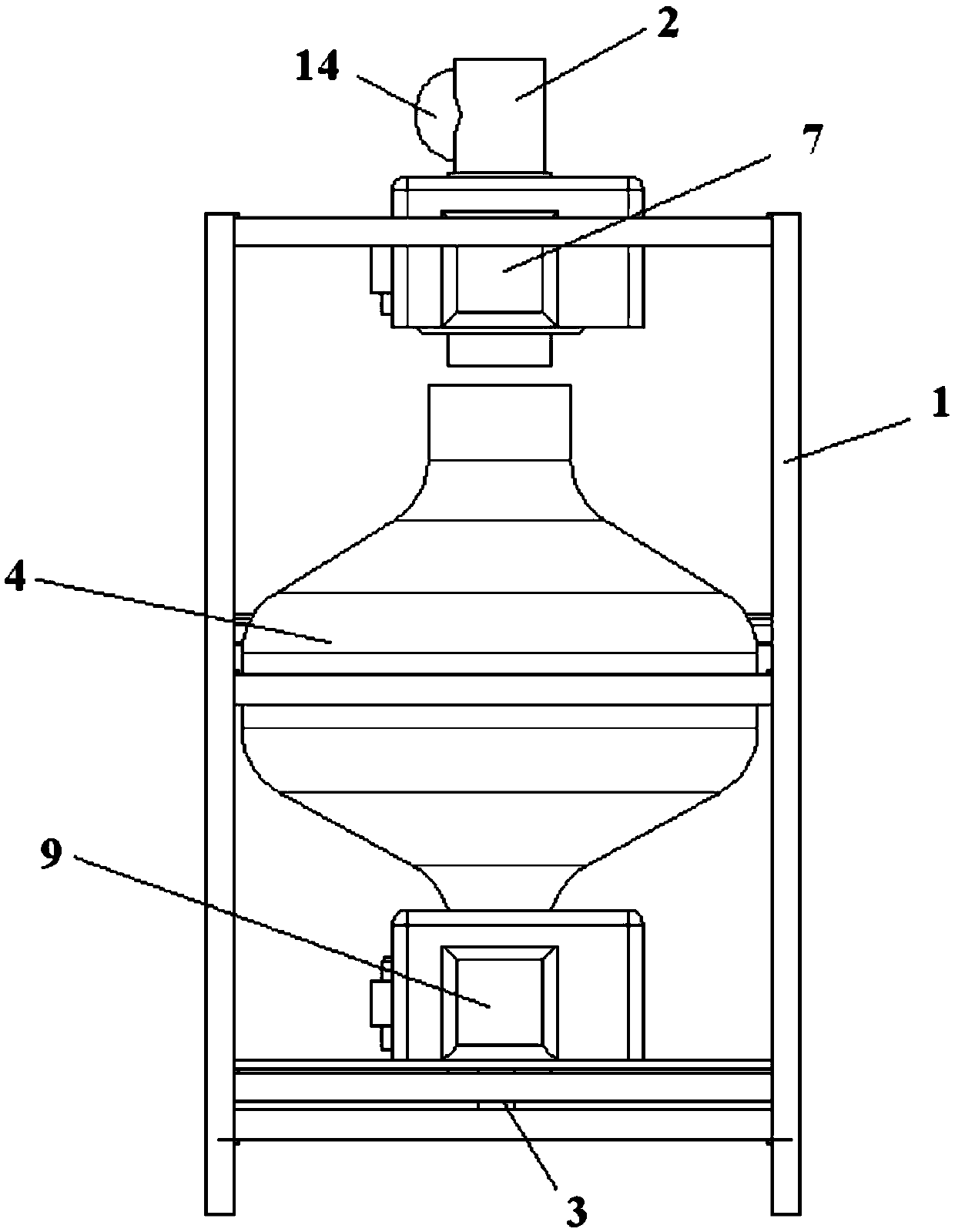

[0048] This embodiment provides a real-time automatic measurement device for runoff sediment, such as Figure 1 to Figure 5Shown, comprise bracket housing 1, the top surface of bracket housing 1 is fixedly installed with sample inlet 2, and weighing scale 3 is installed in bracket housing 1, and sampler 4 is installed on weighing scale 3, and sampler 4 The top is separated from the sample inlet 2, so that the weighing scale 3 does not measure the weight of the sample inlet 2, the bottom of the sampler 4 is provided with a sample discharge port 5, and the outer wall of the sampler 4 is also provided with an overflow for calibrating the volume of the sampler. Orifice 6;

[0049] A sampling valve 7 is installed on the sampling port 2, and the sampling valve 7 is driven by a sampling valve control motor 8, and a sampling valve 9 is installed on the sampling port 5, and the sampling valve 9 is driven by a sampling valve control motor 10;

[0050] A first fluid sensor 11 is install...

Embodiment 2

[0061] This embodiment provides a kind of measuring method that adopts the measuring device in embodiment 1, such as Figure 6 As shown, the method specifically includes the following steps:

[0062] Step 1, the measuring device is installed at the runoff outlet of the runoff sub-district or the bayonet station of the watershed, and after the measuring device is installed and positioned, the zero point of the measuring scale 3 is adjusted;

[0063] Step 2, the measuring device is initially in a standby state, the sampling valve 7 and the sampling valve 9 are both opened, and the first fluid sensor 11 detects in real time whether there is runoff;

[0064] Step 3, when the first fluid sensor 11 detects runoff, the measuring device is powered on;

[0065] Step 4, use the runoff to clean the sampler 4 for 10 s, close the sampling valve 7, empty the sampler 4 for 30 s, close the sample discharge valve 9, keep the measuring device stable for 60 s, weigh the sampler 4 with the weigh...

Embodiment 3

[0070] This embodiment uses the measuring device of embodiment 1 and the measuring method of embodiment 2 to measure the runoff sediment, and the measurement process is as follows:

[0071] 1. Preparation of standard sediment samples

[0072] Preset sediment concentration from 2-300kg / m 3 , of which 2-10kg / m 3 One increment per 2kg / m3, 10-100kg / m3 3 per 10kg / m 3 One increment, 100-300kg / m 3 Every 50kg / m 3 an increment. The soil to be tested is air-dried loess soil, and the moisture content of the air-dried soil is measured by the drying method, and the air-dried soil is converted into an oven-dried soil. Calculate and weigh the air-dried soil with a preset sediment concentration, add the air-dried soil to the sampler of the detector, and fill it with water. to be tested.

[0073] 2. Use the measuring device in Example 1 and the measuring method in Example 2 to measure the prepared standard sediment samples to obtain the runoff sediment content.

[0074] 3. Repeat thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com