PMOS structure and formation method thereof

A gate structure, silicon germanium technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the hot carrier injection effect and the deterioration of negative bias temperature instability, the increase of PMOS gate current, Reduce the stability of the device and other problems, achieve the effect of improving the hot carrier injection effect, improving stability, and reducing the probability of diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

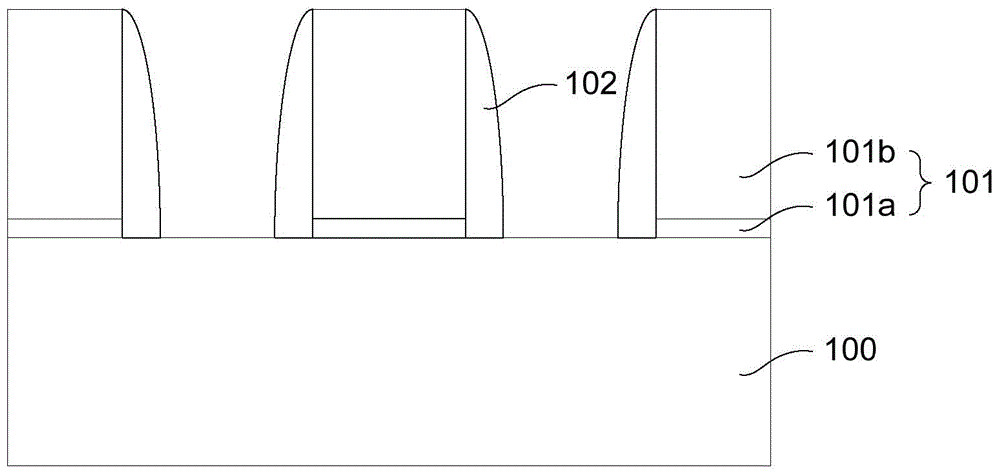

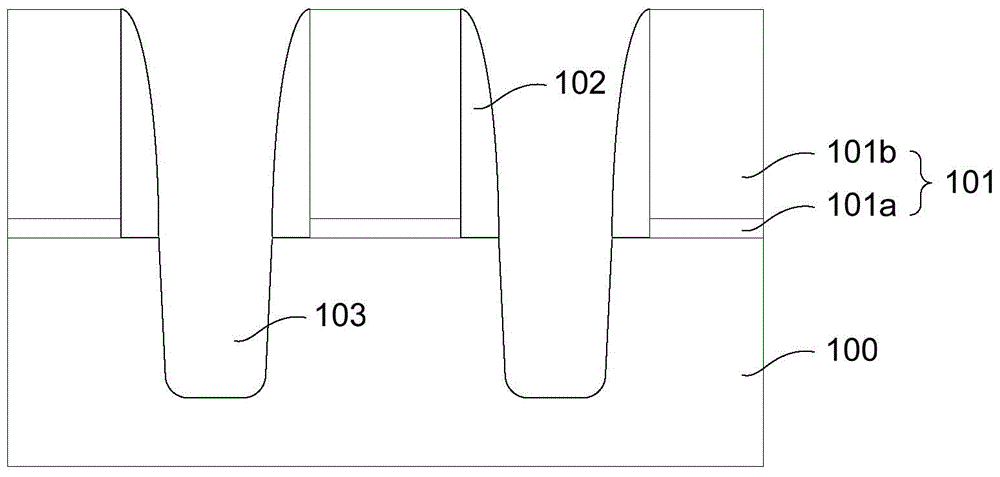

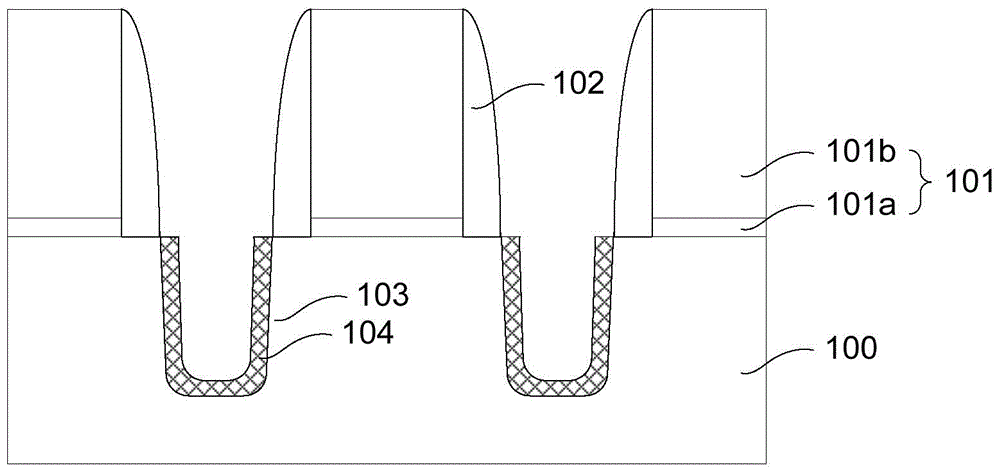

[0032] It can be seen from the background art that the PMOS structure formed by the prior art process has the problems of electrical performance drift and electrical performance degradation. For this reason, the semiconductor device and its formation process were studied, and it was found that when the embedded silicon germanium layer is formed by selective epitaxial growth in the PMOS source and drain regions, the in-situ doped boron ions will diffuse in the subsequent annealing process , increasing the gate current leads to a drift in the electrical performance of the PMOS. The germanium ions in the germanium-silicon layer will also diffuse into the channel, which not only changes the hole mobility rate, but also changes the total charge quantity in the channel, resulting in the deterioration of the hot carrier injection effect and negative bias temperature instability. , greatly reducing the electrical performance of the PMOS.

[0033] In order to solve the above problems,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com