Biomaterial product based on sunflower seed shells and/or sunflower seed hulls

A biomaterial, sunflower seed shell technology, applied in the field of biomaterial products, can solve the problems of reducing the breaking strength and not easy to break, and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0081] Bioplastic "ABS / SPC30"

[0082] 520kg ABS (acrylonitrile-butadiene-styrene), 300kg shell, 30kg additive (odor), 30kg additive (impact toughness), 30kg additive (humidity), 30kg additive (rheological properties), 30kg additive (adhesion enhancer) , 30kg additive (entrainer).

[0083] The mixture of said materials is then fed as usual to a compounding process so that the desired biomaterial product can then be produced in the desired form from the compounded material resulting therefrom, for example by means of extrusion or injection molding or rotomolding or Manufactured by pressing techniques or thermoforming methods.

[0084] As an adhesion promoter additive, for example the product "SCONATPPP8112FA" (adhesion modifier for polypropylene-natural fiber-composites and TPE-S-composites) from the company BYK, Additives & Instruments is suitable , Technical Manual, Standard 07 / 11, Products and Companies of the ALTANA-Group. The technical data sheet for this product is lis...

no. 2 example

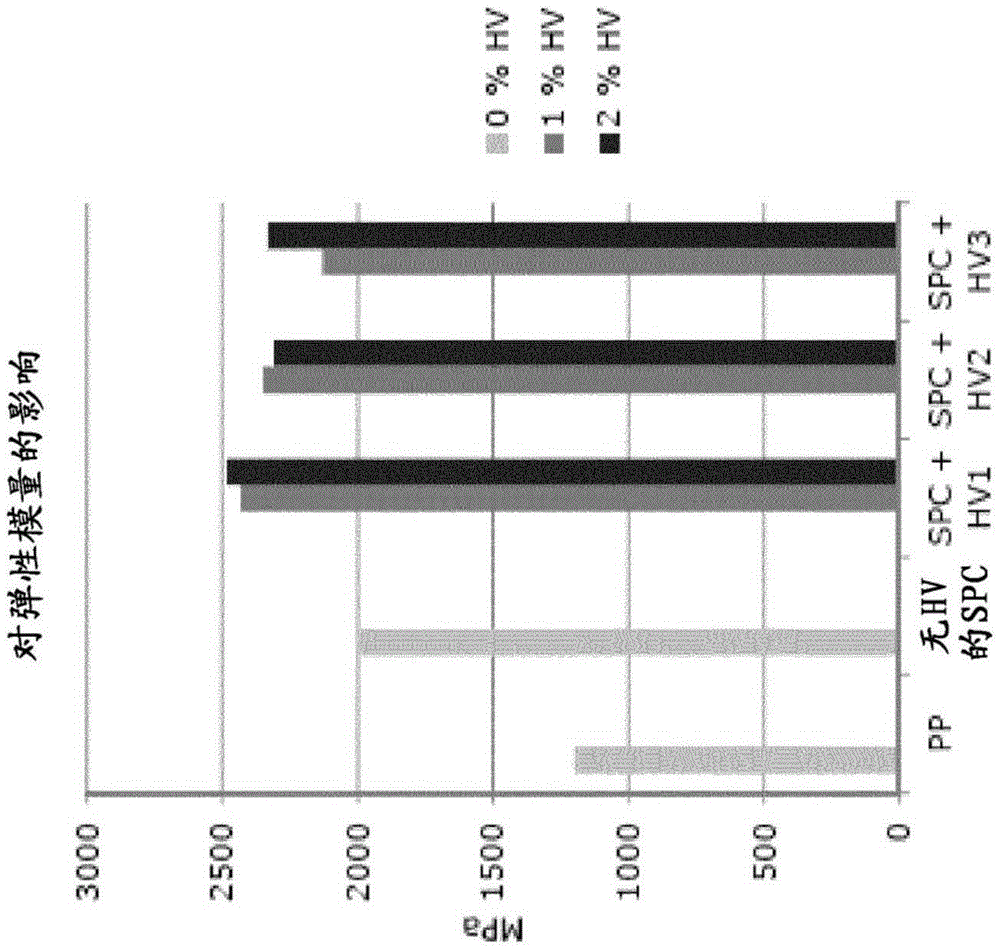

[0088] Another component of another composite material (biomaterial) with internal designation "PP / SPC50" consists of:

[0089] 45%PPMoplenEP300K,Gr

[0090] 50% sunflower shells

[0091] Irgafos168, Pu, 0.20%

[0092] Irganox1076, Pu, 0.30%

[0093] BYKP4200, 2.00%

[0094] SconaTPPP8112FA, Pu, 2.5%

[0095] The components mentioned are compounded as usual and the compounded material produced therefrom can subsequently be used by means of the methods described above and / or below in this application, such as extrusion, injection molding, deep drawing, rotational molding Forming, pressing techniques, thermoforming methods to manufacture desired plastic products.

[0096] As far as compounding (Compoundieren) or compounding (Compoundierung) is mentioned in the present application, it thus means the processing of sunflower seed hull material or sunflower seed husk material with plastic and in particular the refining process, wherein the refining process also includes The ad...

PUM

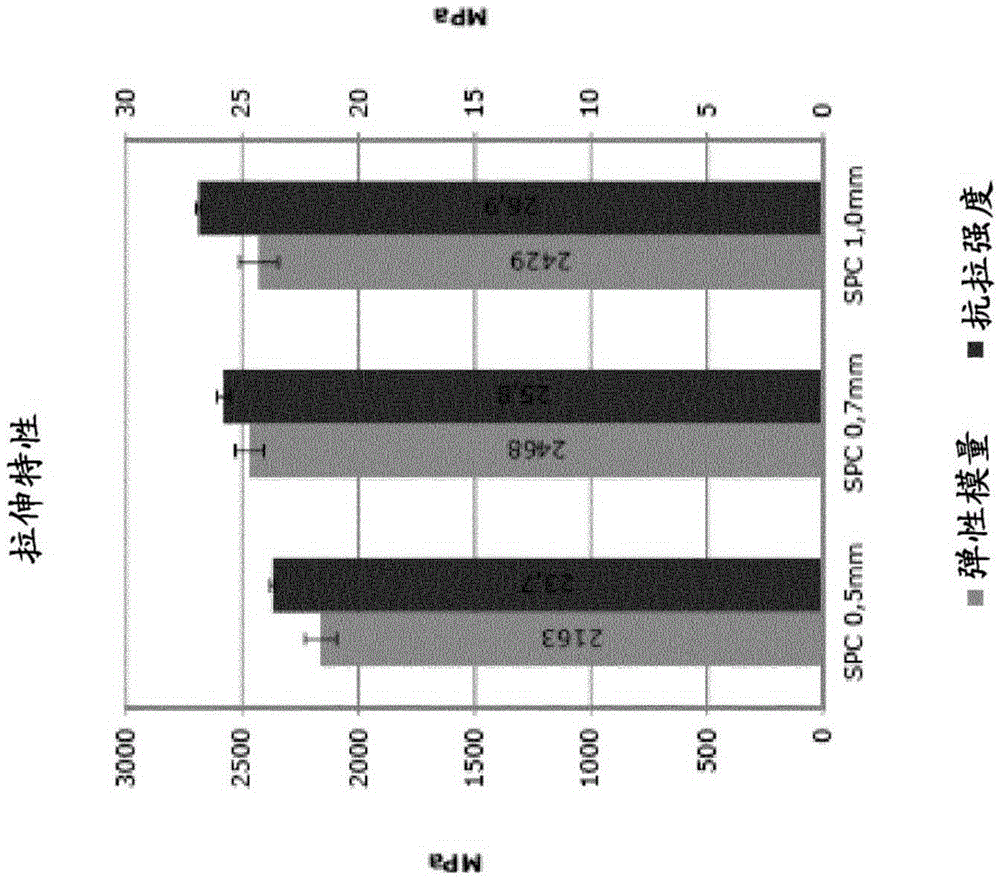

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com