Pot noodle placing and encasing device

A technology of noodle packing and barrel noodle, which is applied in the field of industrial robot application, can solve the problems of high sanitation requirements in the noodle production workshop, affect the sanitation of the noodle environment, and affect the physical and mental health of workers, and achieve simple structure, easy control, and easy grasping. Take the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

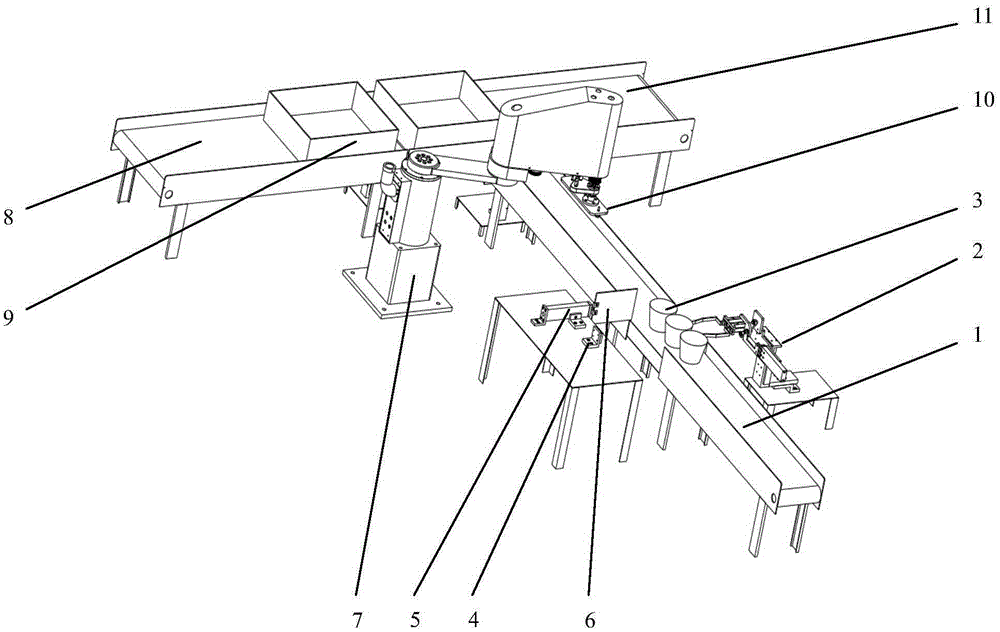

[0033] Do further description below in conjunction with accompanying drawing:

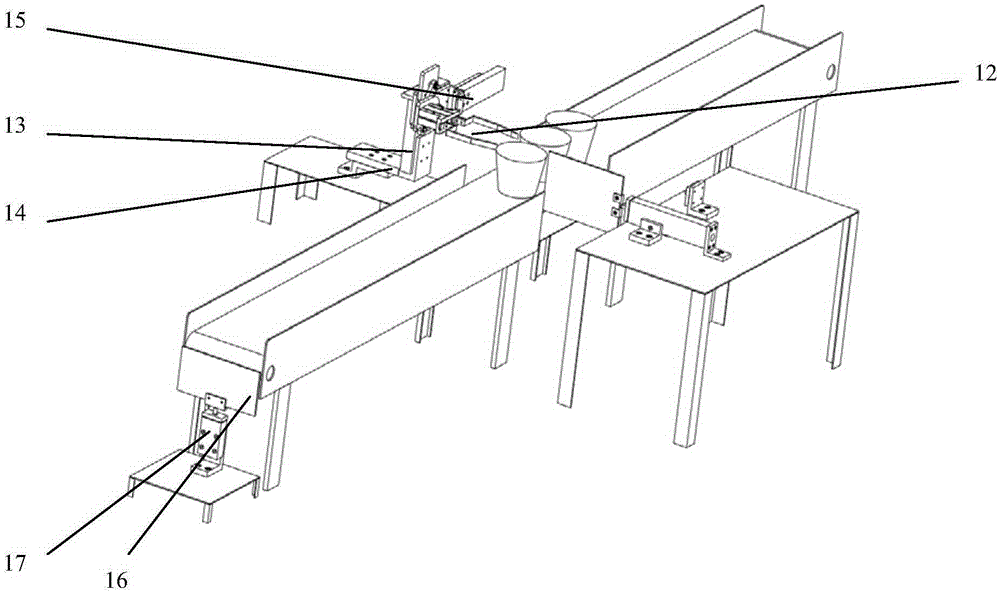

[0034] The device of the present invention includes three parts: a noodle placing line, a SCARA handling robot 7, and a barrel noodle packing line; wherein the barrel noodle placing line further includes a first conveyor belt 1, a barrel noodle turning robot 2, a photoelectric sensor 4, and a first baffle 6 , the second baffle 16, the overturning robot 2 has four degrees of freedom, the overturning robot has three drives of the second cylinder 14, the third cylinder 13, and the fourth cylinder 15, and the end gripper 12 is driven by a mobile drive pair to realize the bucket surface Grab and relax. The second flapper is driven by the fifth cylinder 17 . The SCARA handling robot is a four-degree-of-freedom series robot. Three suction cups 10 are fixed at the end to carry the placed barrel surface. Realized by internal belt drive.

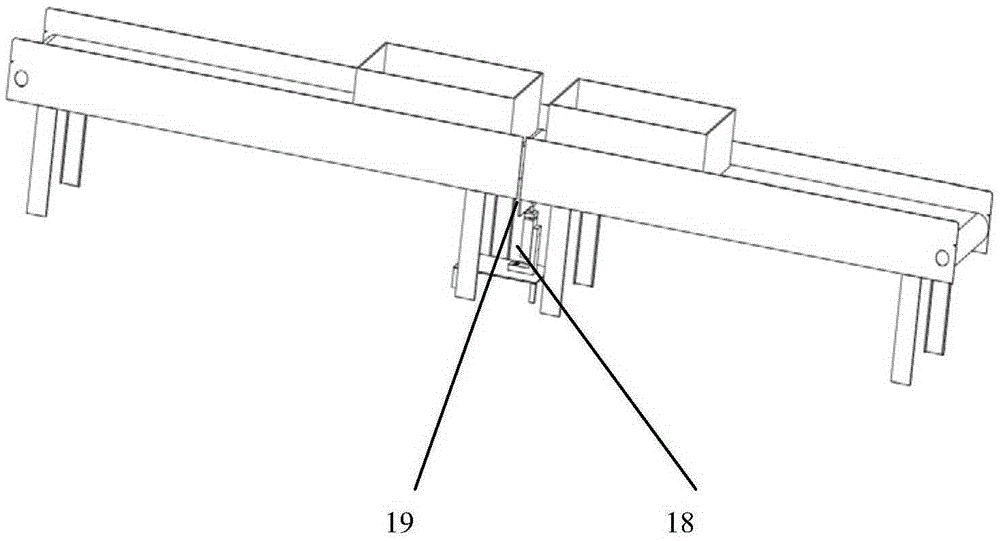

[0035] The bucket surface packing line comprises a second conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com