A low-emission, high heat-resistant polyamide composite material and its preparation method

A composite material and polyamide technology, which is applied in the field of high heat-resistant polyamide composite material and its preparation, and low emission, can solve the problems of long-term heat resistance and organic volatility without considering the material, and achieve low haze and low Odor, effect of improving heat resistance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

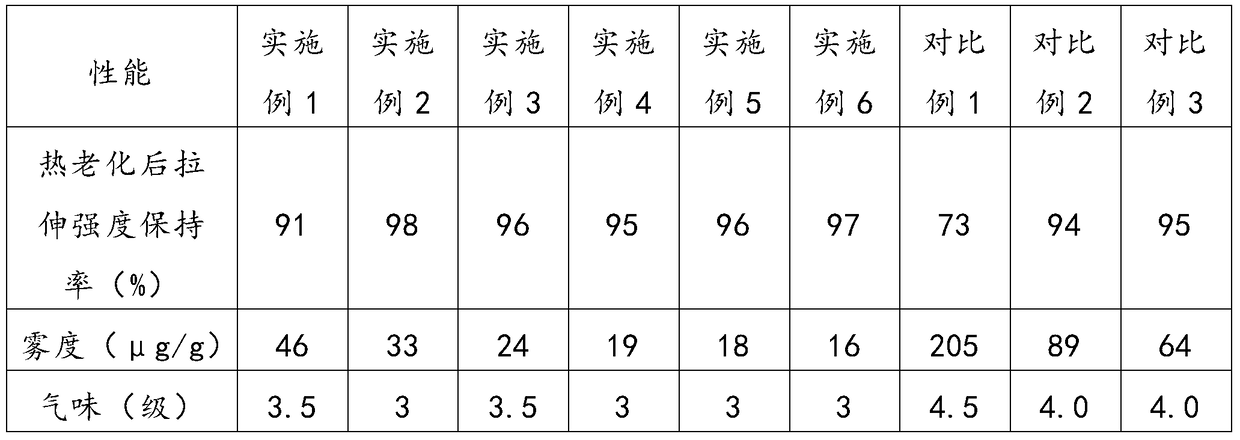

Examples

Embodiment 1

[0049] Put 92.7kg of polyamide, 0.3kg of copper salt composite heat stabilizer and 2kg of clay into a high-speed mixer with a rotation speed of about 1000rpm and mix for 3-5 minutes, then feed through the main feeder of the twin-screw extruder, talc powder 5kg is fed through the side feeder of the twin-screw extruder, and extruded and granulated by twin-screw with two vacuum devolatilization devices. The extrusion temperature is 250°C, the vacuum degree is 0.08MPa-0.1MPa, and the main engine speed of the twin-screw extruder is 400 rpm.

[0050] The model and manufacturer of raw materials are shown in the table below:

[0051] raw material

Embodiment 2

[0053] Put 64.2kg of polyamide, 0.8kg of copper salt composite heat stabilizer, 2kg of clay and 3kg of molecular sieve into a high-speed mixer with a rotation speed of about 1000rpm and mix for 3-5 minutes, then feed through the main feeder of the twin-screw extruder , and then feed 30kg of glass microspheres through the side feeder of the twin-screw extruder, and extrude and granulate through the twin-screws equipped with two vacuum devolatilization devices. The extrusion temperature is 270°C, the vacuum degree is 0.08MPa-0.1MPa, and the main engine speed of the twin-screw extruder is 400 rpm.

[0054] The model and manufacturer of raw materials are shown in the table below:

[0055] raw material

Embodiment 3

[0057]Put 69kg of semi-aromatic polyamide, 0.5kg of copper salt composite thermal stabilizer and 0.5kg of molecular sieve into a high-speed mixer with a rotation speed of about 1000rpm and mix for 3-5 minutes, then feed through the main feeder of the twin-screw extruder , and then feed 30kg of glass fiber through the side feeder of the twin-screw extruder, and then extrude and granulate through the twin-screw with two vacuum devolatilization devices. The extrusion temperature is 310°C, the vacuum degree is 0.08MPa-0.1MPa, and the main engine speed of the twin-screw extruder is 400 rpm.

[0058] The model and manufacturer of raw materials are shown in the table below:

[0059] raw material

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com