A kind of clean preparation method of weak basic arylamine azo disperse dye

An aromatic amine azo, disperse dye technology, applied in the direction of azo dyes, monoazo dyes, organic dyes, etc., can solve the problems of difficult post-processing, waste of resources, etc., to achieve environmental protection, saving washing water, energy saving significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A cleaning preparation method for weakly basic arylamine azo disperse dyes, comprising the steps of:

[0036] (1) Add the weakly basic arylamine diazonium double salt solid into the coupling component dispersion, and react at 25-50°C for 0.1-5 hours;

[0037] (2) After the reaction is completed, the reaction solution is filtered, and the filter cake is collected and dried to obtain a weakly basic arylamine azo disperse dye.

[0038] Wherein, the weakly basic arylamine diazonium double salt solid has a structure of general formula (I):

[0039]

[0040] In formula (I):

[0041] R 1 -CN, -NO 2 , -Cl, -Br or -I;

[0042] R 2 -H, -CN, -NO 2 , -Cl, -Br or -I;

[0043] x - 1,5-naphthalene disulfonic acid, fluoroboric acid, 2,7-naphthalene disulfonic acid, 2,6-naphthalene disulfonic acid, 1,6-naphthalene disulfonic acid, 1,3,6-naphthalene trisulfonic acid , 1,3,5-naphthalene trisulfonic acid, 1,3-benzenedisulfonic acid, 1,4-benzenedisulfonic acid, 2,6-anthracene di...

Embodiment 1

[0048] Put 200g N,N-dicyanoethylaniline, 1000g water, 2g sodium methylenebismethyl naphthalene sulfonate (MF), 600g quartz sand with a particle diameter of 2mm into a vertical sand mill, and turn it at a speed of 500 rpm / Sand milling under the condition of 2.5 hours for 2.5 hours, measure the particle size distribution of the obtained dispersion liquid, and the average particle size is 7-8 μm. After filtration, the coupling component dispersion liquid was obtained, and the mass percentage of N,N-dicyanoethylaniline was 16.6%.

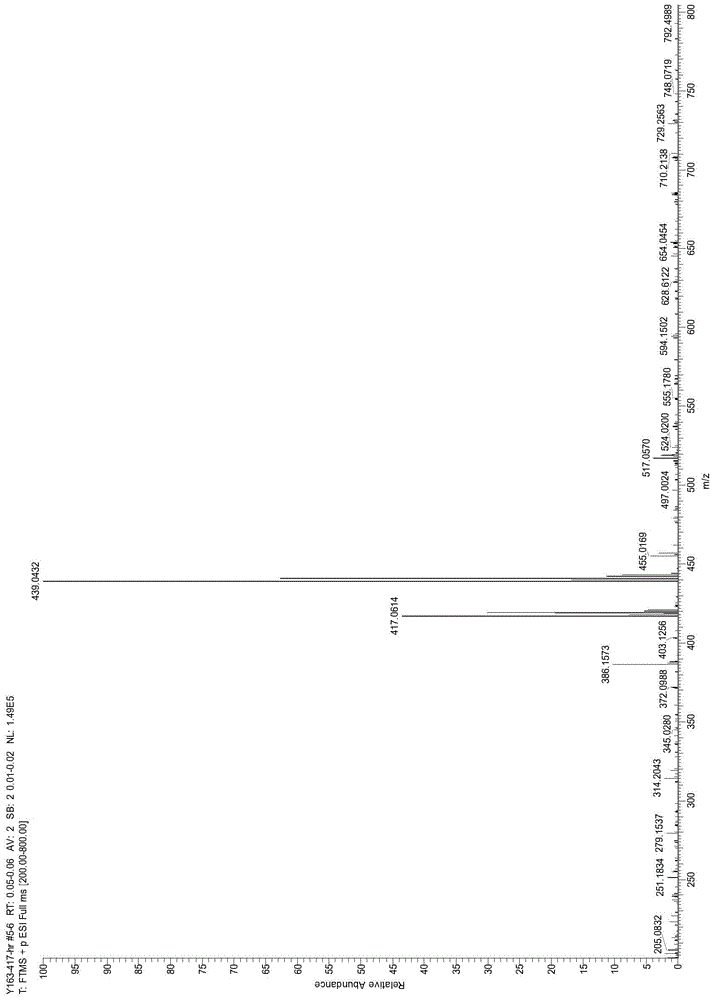

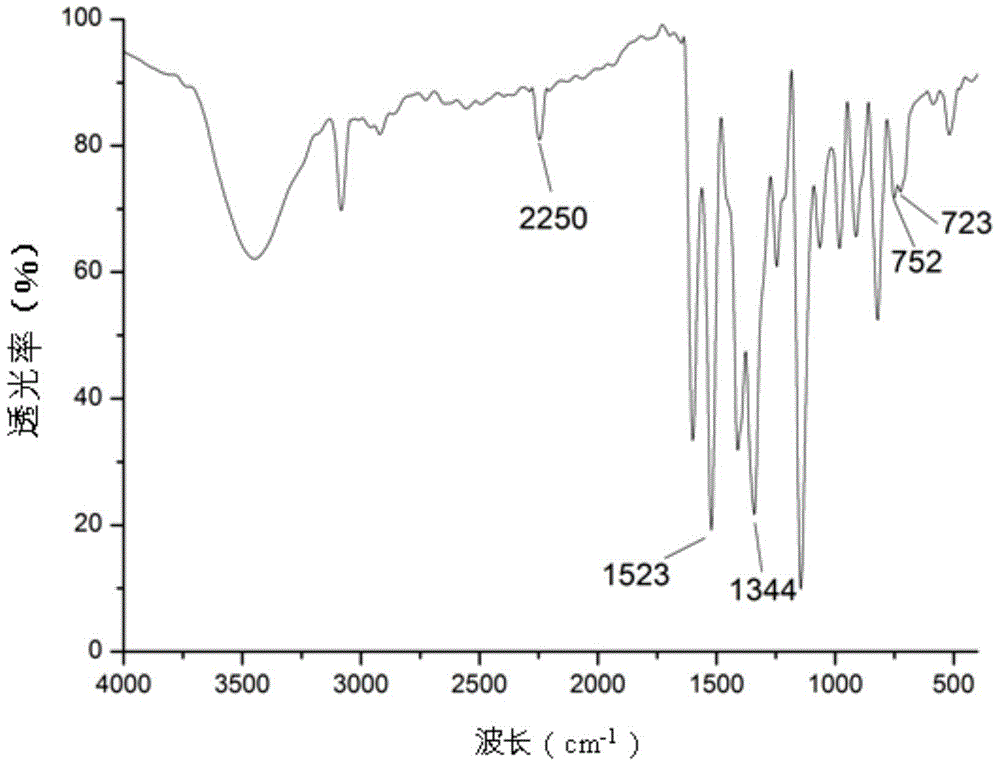

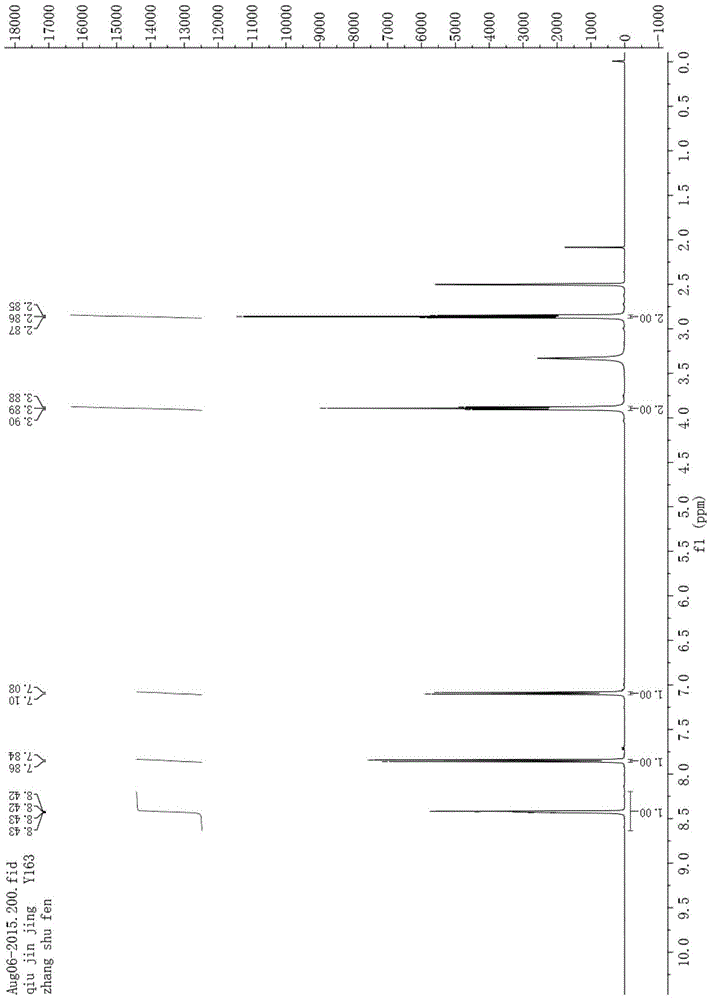

[0049] Take 119.9g of the above-mentioned coupling dispersion liquid and add it to 100ml of water, stir at room temperature, add 50.6g of 1,5-dinaphthalenesulfonic acid diazonium double salt of 2,6-dichloro-4-nitroaniline within half an hour In the coupling solution, react at 30 degrees centigrade for 2 hours, check with the diazonium ring to confirm the disappearance of the diazonium salt, filter, wash with distilled water until neutral, and obtain 41...

Embodiment 2

[0053] Put 200g of N,N-dicyanoethylaniline, 1200g of water, 800g of quartz sand with a particle size of 2mm, and 2g of MF into a vertical sand mill, and grind at a speed of 100 for 5 hours. Its particle size distribution has an average particle size of 7-8 μm. After filtration, the coupling component dispersion liquid was obtained, and the mass percentage of N,N-dicyanoethylaniline was 16.6%. Take 119.9g of the above coupling component dispersion and add it to 200g of water, stir at room temperature, add 47.1g of 1,5-dinaphthalenesulfonic acid diazonium double salt of 2-chloro-4-nitroaniline within half an hour to the coupling solution, reacted at 35 degrees centigrade for 3 h, checked with the diazonium ring to confirm that the diazonium salt disappeared, filtered, washed with distilled water until neutral, and obtained 38 g of the following structure (compound 2#) disperse dye, yield 98.9%.

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com