Preparation method for three-dimensional graphene/phase change heat conduction composite material

A technology of phase change heat conduction and composite materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of low thermal conductivity and easy leakage of phase change energy storage materials, and achieve simple preparation process, low cost, The effect of outstanding practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Weigh 2 g of graphite oxide, add 500 ml of deionized water, stir for 30 min, and sonicate for 2 h to prepare a 4 mg / ml graphene oxide solution.

[0052] (2) Weigh 2g of cetyl alcohol, heat it at 80°C, cetyl alcohol melts, add 10.4ml of graphene oxide solution and Hcl solution, pH is 3, stir for 5min, stirring speed is 1500r / min, and a stable emulsion is obtained .

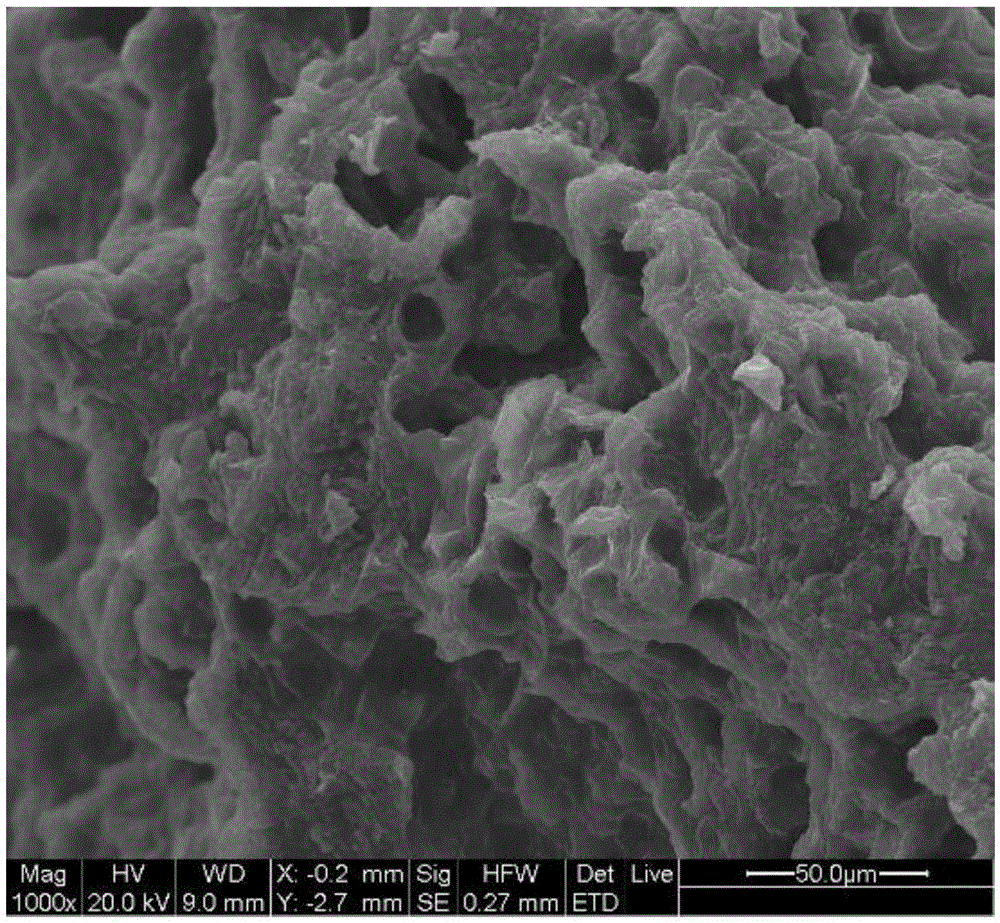

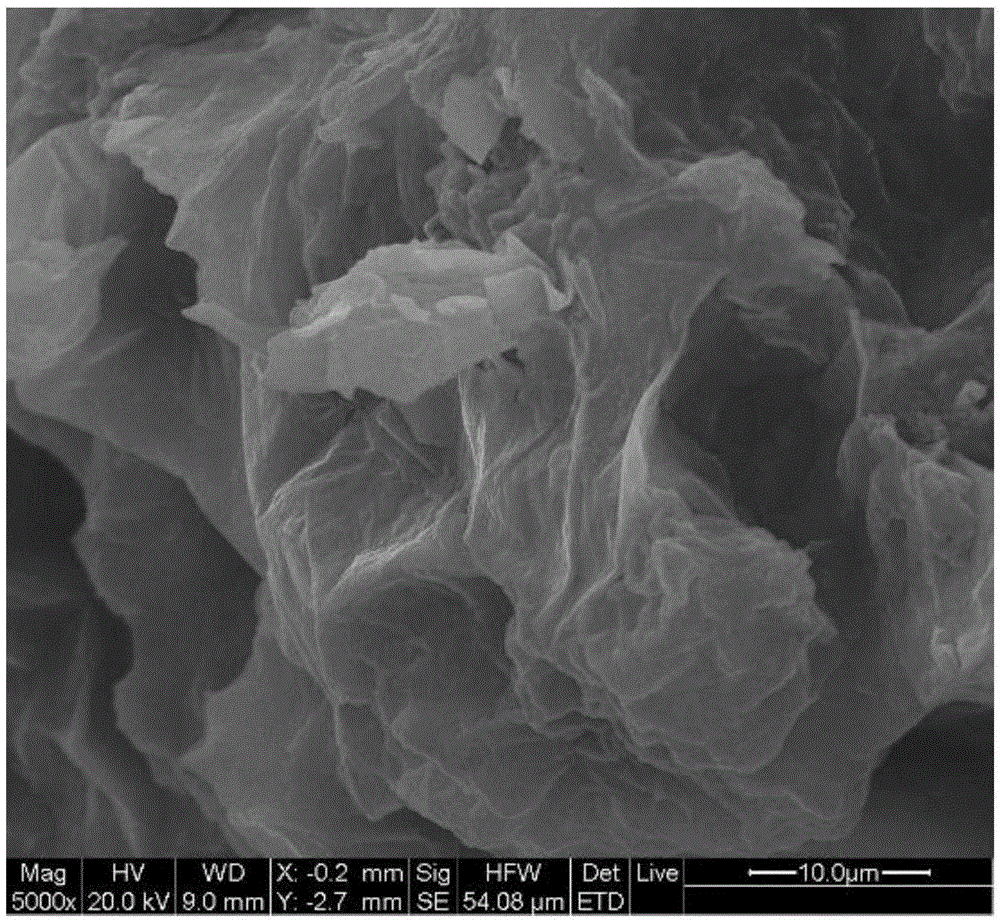

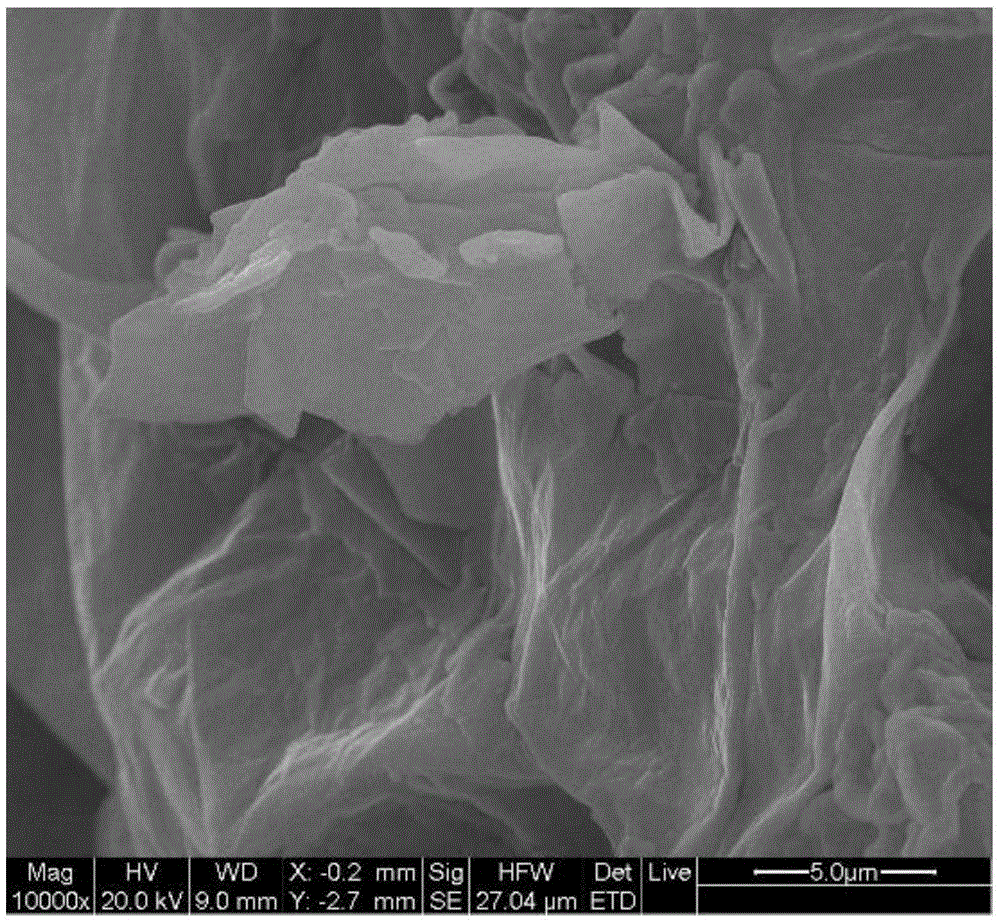

[0053] (3) Put the emulsion into a closed glass bottle, add an appropriate amount of hydrazine hydrate (1 mg graphene oxide corresponds to 0.1-0.4 μL), and heat it at 90°C for 2 hours to obtain a three-dimensional graphene / phase transition separated from the water phase Thermally conductive composite material, just take out the block and dry it.

[0054] Soak the three-dimensional graphene / phase-change heat-conducting composite material prepared in this example in ethanol, and heat at 80°C for 5 minutes to remove cetyl alcohol, pour out the ethanol / cetyl alcohol solution, add ethanol again, repeat The ...

Embodiment 2

[0058] (1) Weigh 2 g of graphite oxide, add 500 ml of deionized water, stir for 30 min, and sonicate for 2 h to prepare a 4 mg / ml graphene oxide solution.

[0059] (2) Weigh 2g of cetyl alcohol, heat it at 80°C until the cetyl alcohol melts, add 20ml of graphene oxide solution and Hcl solution, the pH is 3, stir for 2min at a stirring rate of 10000r / min to obtain a stable emulsion.

[0060] (3) Put the emulsion into a closed glass bottle, add an appropriate amount of hydrazine hydrate (1 mg graphene oxide corresponds to 0.1-0.4 μL), and heat it at 90°C for 2 hours to obtain a three-dimensional graphene / phase transition separated from the water phase Thermally conductive composite material, just take out the block and dry it.

Embodiment 3

[0062] Preparation of Graphene Oxide Cetyl Alcohol Microcapsules

[0063] (1) Preparation of graphene oxide solution.

[0064] Weigh 2 g of graphite oxide, add 500 ml of deionized water, stir for 30 min, and sonicate for 2 h to prepare a 4 mg / ml graphene oxide solution.

[0065] (2) Weigh 1g of cetyl alcohol, heat it at 80°C until the cetyl alcohol melts, add 20ml of graphene oxide solution and Hcl solution, the pH is 3, stir for 2min at a stirring rate of 10000r / min, and a stable emulsion is obtained.

[0066] (3) Put the emulsion into a closed glass bottle, add an appropriate amount of hydrazine hydrate (1 mg graphene oxide corresponds to 0.1-0.4 μL), and heat it at 90°C for 2 hours to obtain a three-dimensional graphene / phase transition separated from the water phase Thermally conductive composite material, just take out the block and dry it.

[0067] The DSC test curve of the three-dimensional graphene / phase-change heat-conducting composite material that embodiment 1-3 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com