Novel amorphous reinforced valve material

A new type of valve technology, used in lift valves, mechanical equipment, valve devices, etc., can solve problems such as incompetence, and achieve the effects of improving welding performance, reducing costs, and excellent high temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

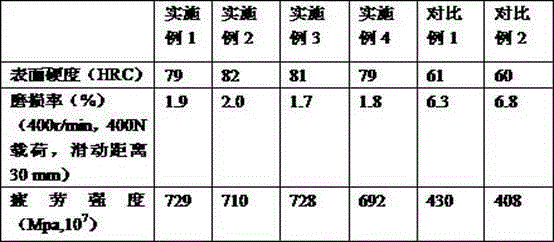

Examples

Embodiment 1

[0022] (1) Prepare the ingredients according to the alloy composition range, C: 0.35%; Si: 0.05%; Mo: 0.14%; Mn: 0.75%; Cr: 0.87%; W: 1.0%; Ce: 0.1%; Nb: 0.1%; Cu: 0.05%. Mix the alloy materials evenly;

[0023] (2) Smelting in a vacuum induction furnace with the temperature controlled at 1650°C for 2 hours;

[0024] (3) Perform three forgings at 1100°C, 1050°C, and 950°C respectively, and control the deformation ratio to 72% to obtain the intake valve blank;

[0025] (4) Insulate at 800°C for 1.5h, quench, then heat to 500°C, hold for 2 hours, and finally air cool;

[0026] (5) Smelting Zr 50 Ti 15 Mo 8 Al 12 W 5 V 5 B 5 Amorphous alloy: the raw materials are configured according to the atomic ratio of the alloy, vacuum smelted, poured and cooled to obtain an amorphous alloy;

[0027] (6) Use milling machine to process the surface finish of the cone surface;

[0028] (7) Welding amorphous alloy on the cone surface;

[0029] (8) Surface finish treatment.

Embodiment 2

[0031] (1) Prepare the ingredients according to the alloy composition range, C: 0.40%; Si: 0.065%; Mo: 0.2%; Mn: 0.80%; Cr: 0.80%; W: 0.9%; Ce: 0.2%; Nb: 0.05%; Cu: 0.1%. Mix the alloy materials evenly;

[0032] (2) Smelting in a vacuum induction furnace with the temperature controlled at 1620°C for 2 hours;

[0033] (3) Perform three forgings at 1100°C, 1050°C, and 950°C respectively, and control the deformation ratio to 73% to obtain the intake valve blank;

[0034] (4) Insulate at 850°C for 1 hour, quench, then heat to 500°C, hold for 2.5 hours, and finally air cool;

[0035] (5) Smelting Zr 50 Ti 15 Mo 8 Al 12 W 7 V 6 B 2 Amorphous alloy: the raw materials are configured according to the atomic ratio of the alloy, vacuum smelted, poured and cooled to obtain an amorphous alloy;

[0036] (6) Use milling machine to process the surface finish of the cone surface;

[0037] (7) Welding amorphous alloy on the cone surface;

[0038](8) Surface finish treatment.

Embodiment 3

[0040] (1) Prepare the ingredients according to the alloy composition range, C: 0.38%; Si: 0.09%; Mo: 0.1%; Mn: 0.56%; Cr: 0.80%; W: 0.50%; Ce: 0.17%; Nb: 0.09%; Cu: 0.086%. Mix the alloy materials evenly;

[0041] (2) Vacuum induction furnace is used for smelting, the temperature is controlled at 1600°C, and smelting is carried out for 2.5 hours;

[0042] (3) Perform three forgings at 1100°C, 1050°C, and 950°C respectively, and control the deformation ratio to 71% to obtain the intake valve blank;

[0043] (4) Insulate at 800°C for 1 hour, quench, then heat to 480°C, hold for 2 hours, and finally air cool;

[0044] (5) Smelting Zr 50 Ti 15 Mo 8 al 12 W 5 V 5 B 5 Amorphous alloy: configure raw materials according to the atomic ratio of the alloy, carry out vacuum melting, pour and cool to obtain amorphous alloy

[0045] (6) Use milling machine to process the surface finish of the cone surface;

[0046] (7) Welding amorphous alloy on the cone surface;

[0047] (8) S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com