Plastic flat filament drawing unit

A technology of plastic flat yarn and plastic extruder, which is applied in stretch spinning, filament/thread forming, and heat treatment of artificial filament. Anti-aging service life, increase service life, reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

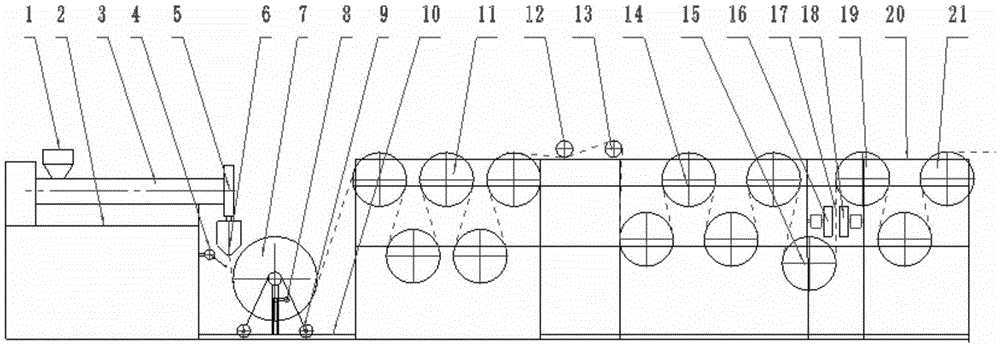

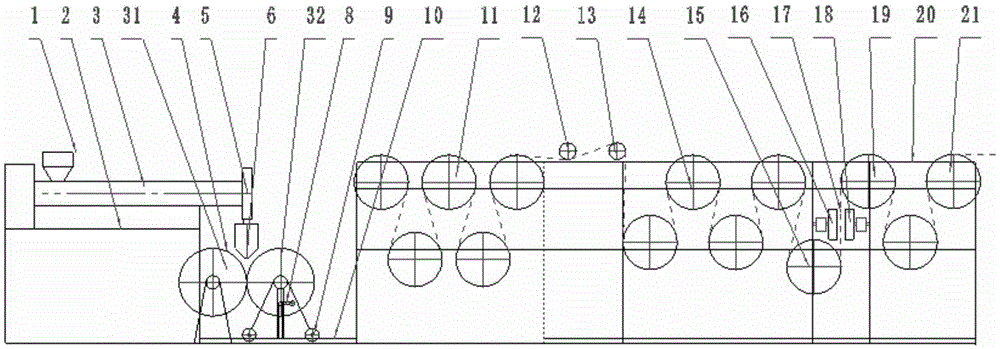

[0021] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

[0022] Such as figure 1 As shown, a PET plastic flat wire drawing unit includes a fixed frame, a plastic extruder, a film cooling and setting device, a film traction roller group, a cutting mechanism, a narrow strip filament traction roller group, a heating device, and a flat filament traction roller group. , power transmission device and electrical appliances, wherein the strip cutting mechanism is installed between the film traction roller group and the narrow strip filament traction roller group, the strip cutting mechanism includes a strip cutter and a pre-cut heater and heating equipment arranged in front of the strip cutter It is installed between the narrow wire drawing roller group and the flat wire drawing roller group.

[0023] There are two fixed frames, namely fixed frame I2 and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com