Method for preparing giant phospholipid vesicle array through point-surface electrode field on basis of contact print technology

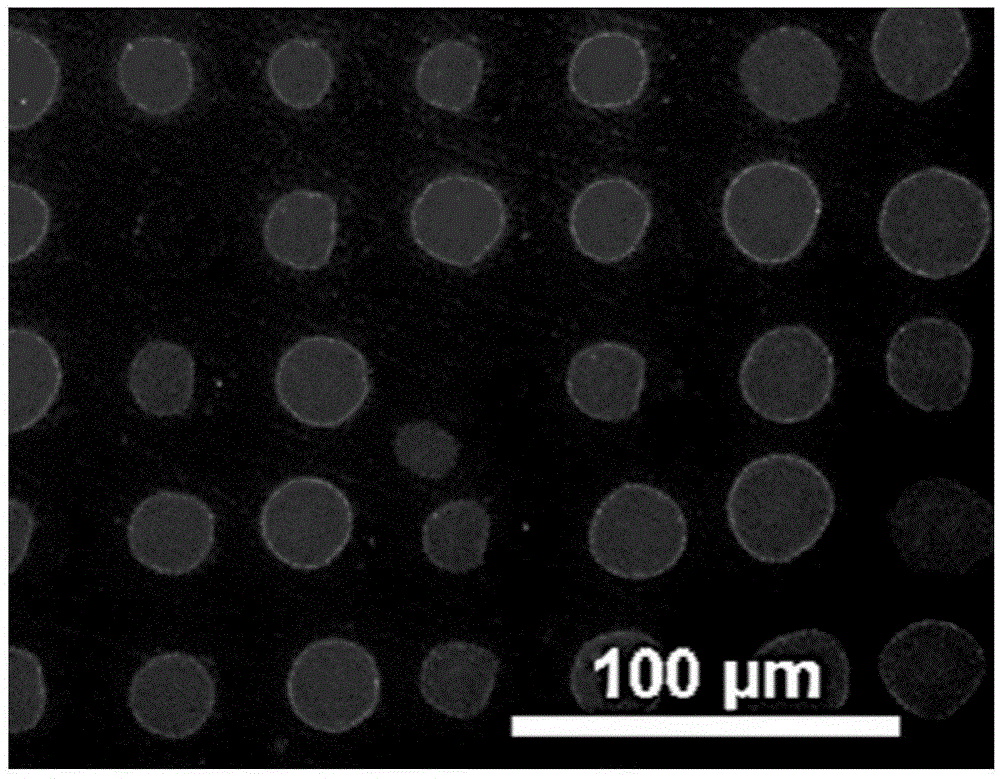

A technology of micro-contact printing and giant phospholipids, which is applied in the preparation of test samples, etc., can solve the problem of single-size control of giant phospholipid vesicles, and achieve good monodispersity of vesicles, single and controllable size, and wide distribution range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

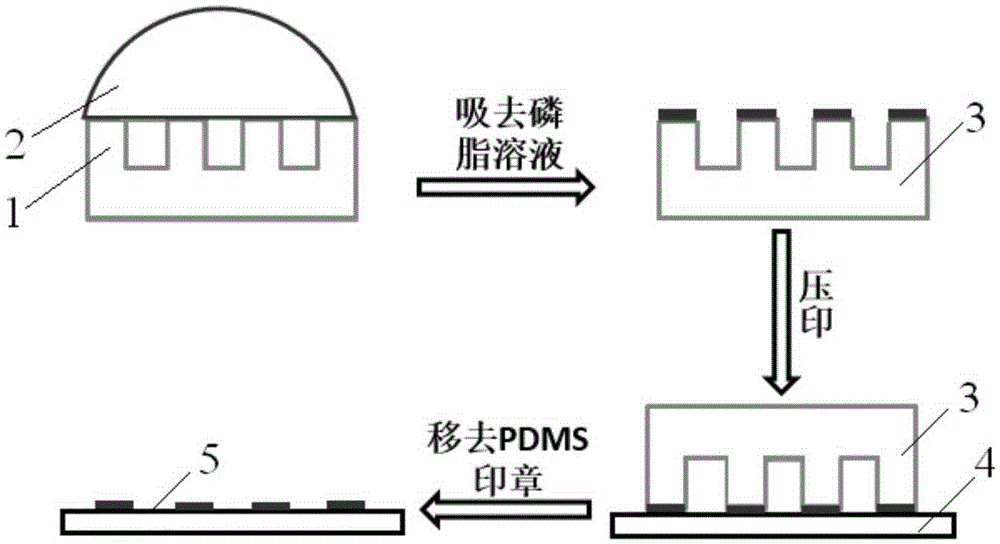

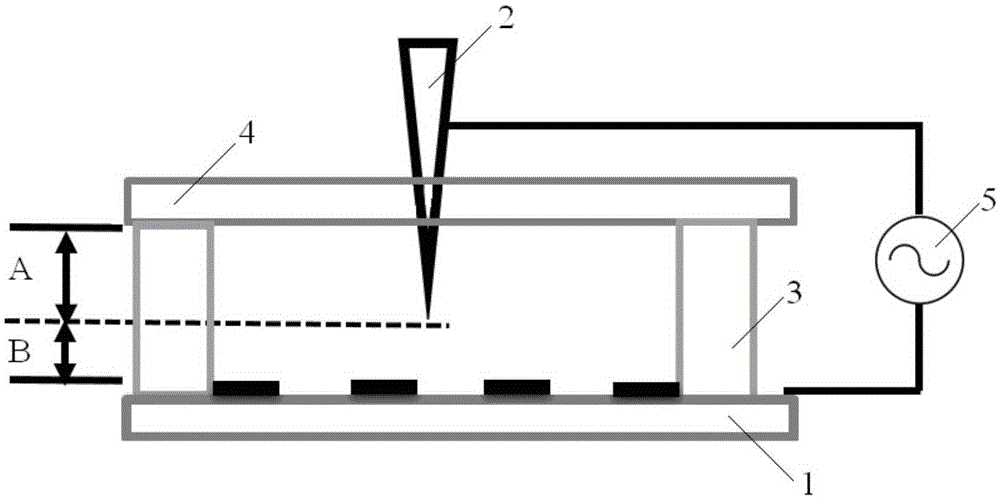

[0025] Embodiment 1: This embodiment is a method for preparing giant phospholipid vesicle arrays based on microcontact printing technology using the electric field of point-surface electrodes, which is completed in the following steps:

[0026] 1. Clean the electrode: first use absolute ethanol to ultrasonically clean the ITO electrode, then use distilled water to ultrasonically clean the ITO electrode, then use nitrogen to dry it, and then use a plasma cleaner to clean the ITO electrode; the cleaned ITO electrode is obtained Electrode: Soak the tungsten needle electrode in hydrochloric acid with a substance concentration of 2mol / L for 3h to 6h, then rinse it with distilled water for 3 to 6 times, and then dry it with nitrogen to obtain the cleaned tungsten needle electrode;

[0027] 2. Cleaning of polydimethylsiloxane stamps with patterns: First, use distilled water to ultrasonically clean the polydimethylsiloxane stamps with patterns, and then use absolute ethanol to clean th...

specific Embodiment approach 2

[0043] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the number of times for ultrasonic cleaning of the ITO electrode described in step 1 using absolute ethanol is 2 to 3 times, and the time for each ultrasonic cleaning is 5min~20min, the ultrasonic power is 40W~80W. Others are the same as the first embodiment.

specific Embodiment approach 3

[0044] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the number of times of using distilled water to ultrasonically clean the ITO electrode described in step one is 2 to 3 times, and the time for each ultrasonic cleaning is 5min~20min, the ultrasonic power is 40W~80W. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com