Beam splitter for wearable display and manufacturing method thereof

A beam splitter and display technology, applied in the field of wearable display, can solve problems such as energy waste, and achieve the effects of environmental friendliness, stable performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings.

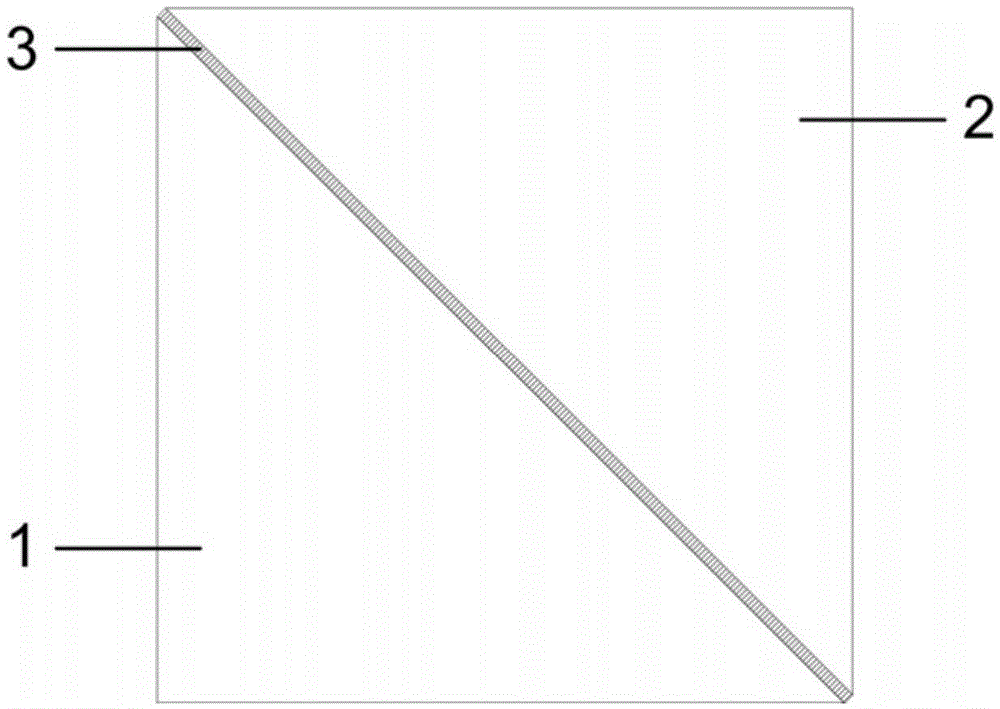

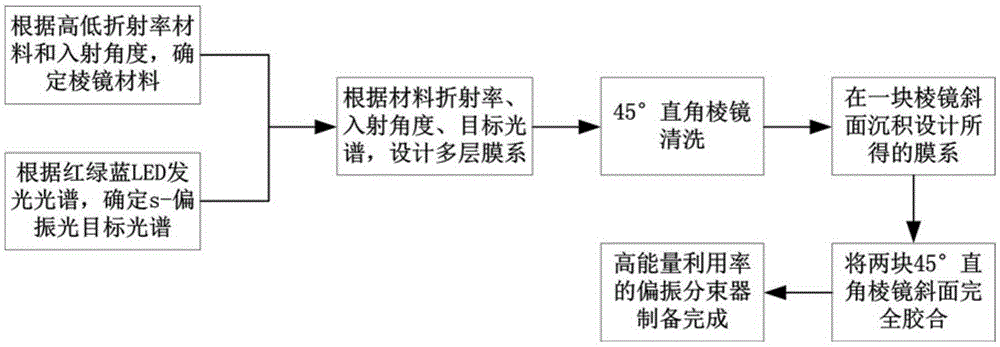

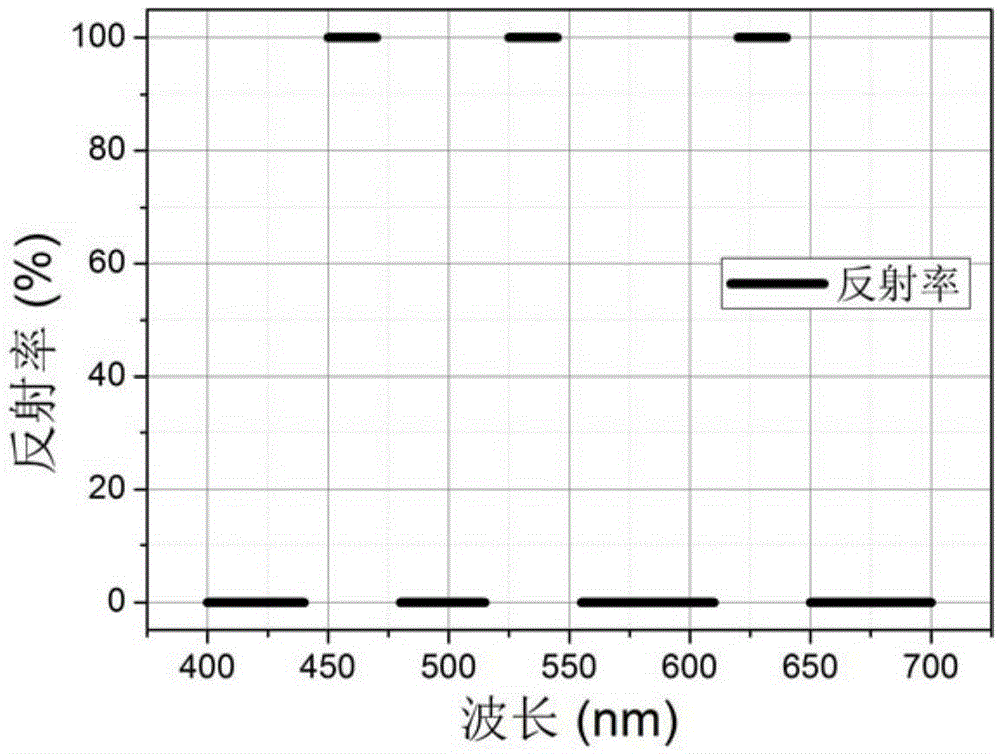

[0037] Such as figure 1 As shown, a high-efficiency wearable display beam splitter is composed of a rectangular prism 1, a rectangular prism 2, and a multilayer film stack 3, wherein the multilayer film stack 3 is deposited on the slope of the rectangular prism 1, and the rectangular prism 1 and the rectangular prism 2 is a prism of the same material and size, and the inclined planes of the two face each other to form a cuboid shape, and are glued together with epoxy resin. The high-efficiency beam splitter for wearable display of the present invention is different from the main beam splitter for wearable display at present. Brewster's angle is used to achieve the effect of traditional polarization beam splitting, and at the same time, the designed high and low refractive index film system is used to realize multi-channel bandpass filtering, so that under th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com