Full-automatic bambix machine and automatic bambix processing method

A food supplement machine, fully automatic technology, applied in home appliances, applications, kitchen utensils, etc., can solve the problems of falling to the bottom of the food supplement cup, low feeding efficiency, and undercooked food supplements, etc., to achieve reduced stirring power and low cost , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

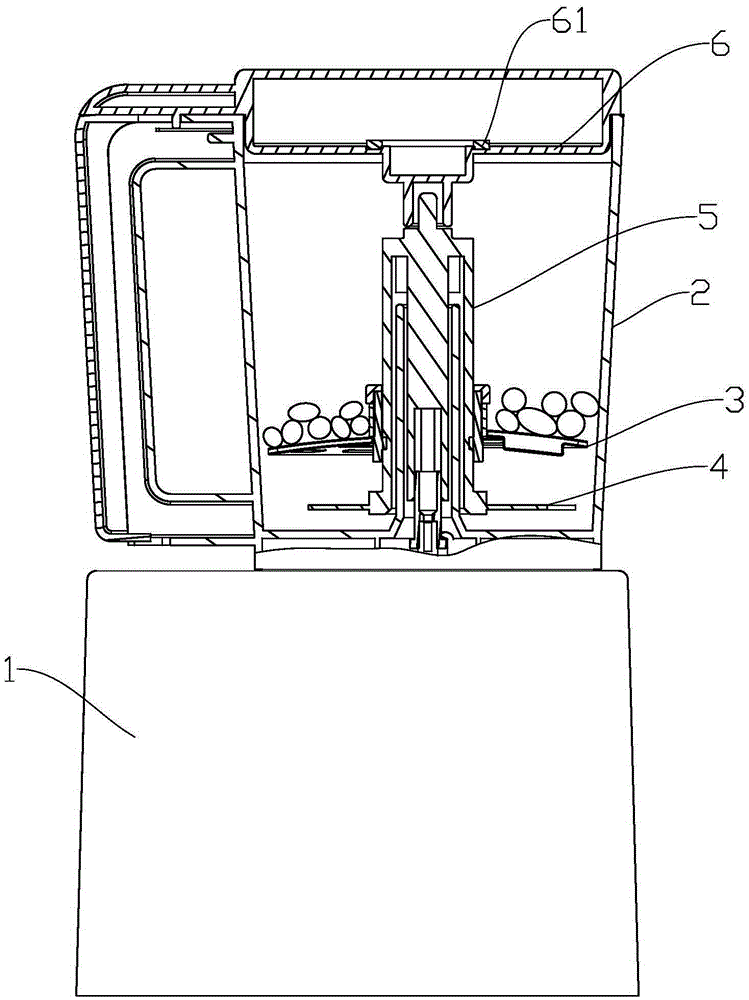

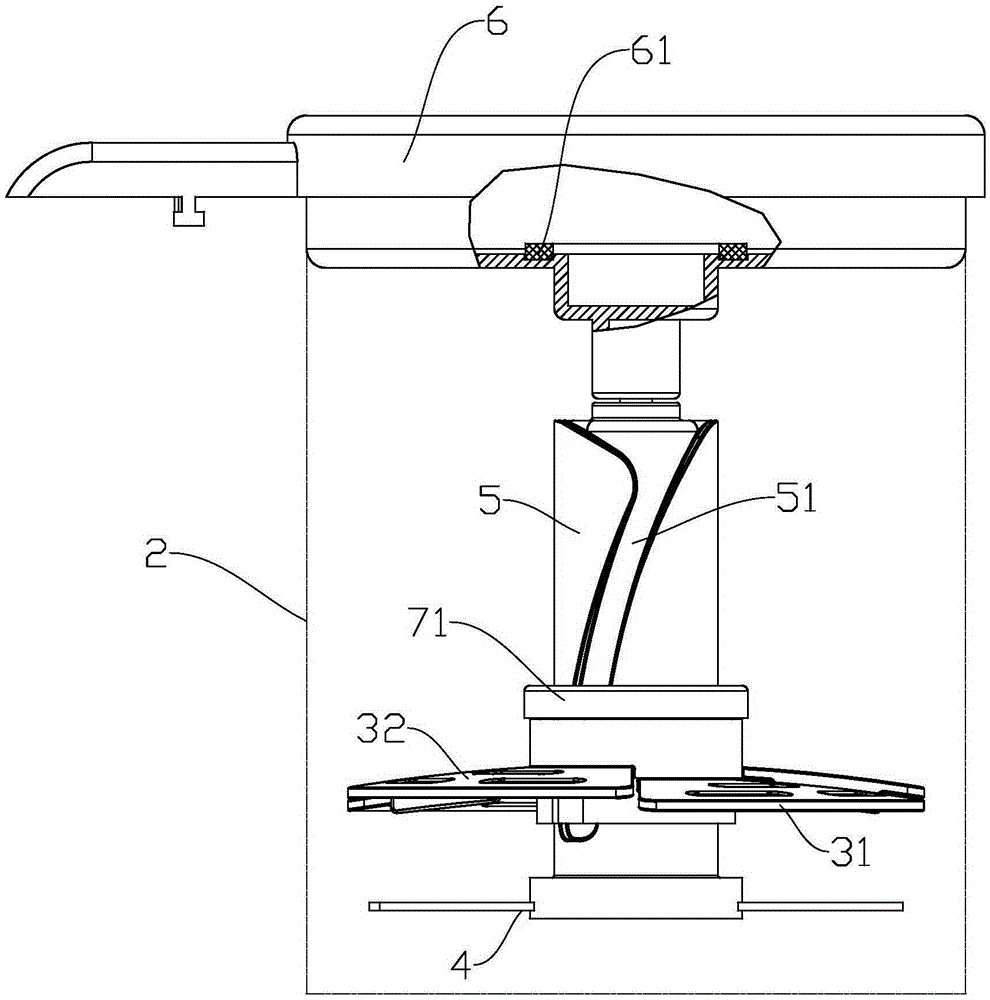

[0072] Such as Figure 1-10 As shown, the fully automatic food supplement machine includes a base 1, a food supplement cup 2, a steaming plate 3, a stirring knife set 4, a rotating shaft 5 for installing the stirring knife set, and a food supplement cup cover 6. It is known that the power device (comprising a motor and a transmission mechanism) for driving the rotating shaft is arranged in the machine base, and a steam generating device is also arranged in the machine base.

[0073] The special features of the fully automatic food supplement machine will be described in detail below in conjunction with the embodiments.

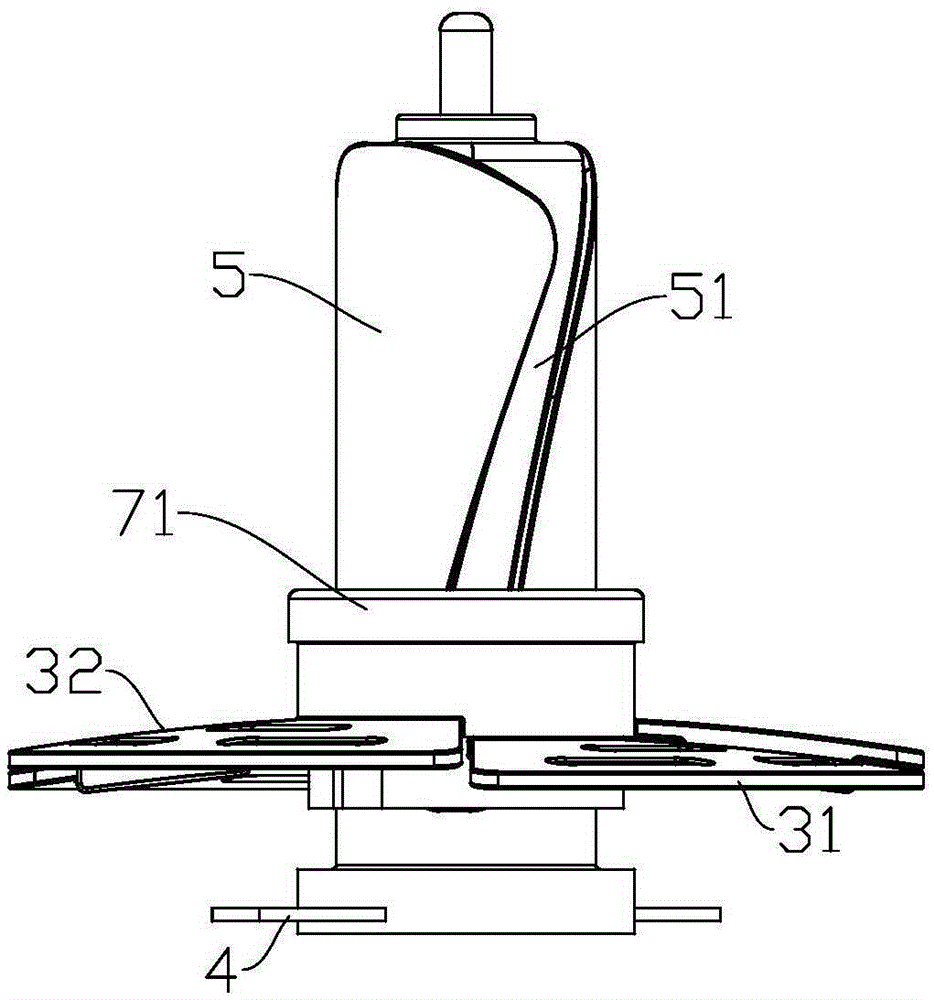

[0074] The steaming tray of the complementary food machine is composed of an active steaming tray 31 and a passive steaming tray 32.

[0075] The active steaming plate 31 is fixedly installed on the active collar 7, and the active collar 7 is sleeved on the rotating shaft 5. At least one lifting guide groove 51 is arranged on the outer surface of the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com