Construction technique for multi-step manual smearing of double-component fireproof paint

A technology of fire-resistant paint and construction technology, which is applied to the device, coating, pre-treatment surface, etc. for coating liquid on the surface, which can solve the problem of high cost of fire-resistant paint, inability to carry out repair work of fire-resistant paint coating, and large waste of fire-resistant paint. and other problems to achieve the effect of improving construction efficiency and construction quality, reducing paint consumption and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

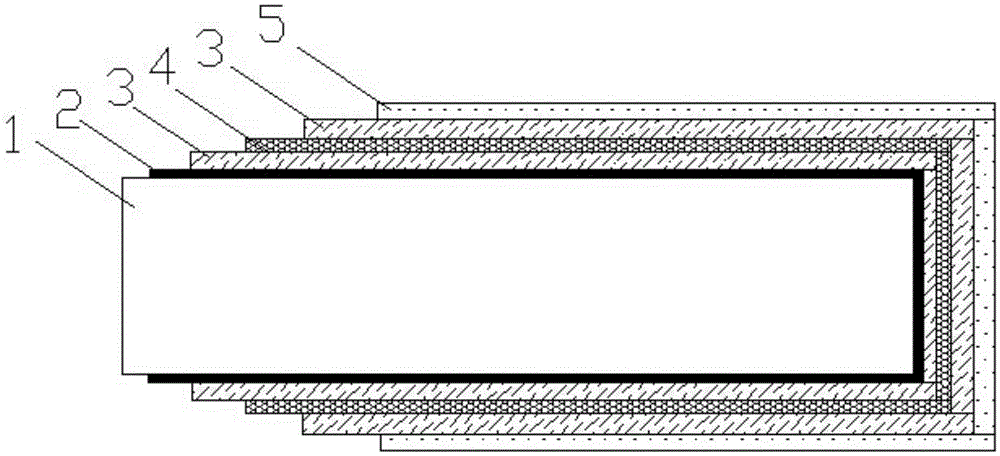

[0026] Such as figure 1 Shown, the present invention adopts following steps:

[0027] Step 1: Sand blast the substrate 1, and make the substrate 1 after sand blasting reach the ISOSa2. The surface of the treated substrate 1 is fully cleaned to remove pollutants such as abrasive residues and dust on the surface of the substrate 1;

[0028] Step 2: Spray the fireproof paint primer 2 on the substrate 1;

[0029] Step 3: Use trowel, trowel, trowel and other tools to evenly scrape the mixed fireproof coating 3 on the fireproof coating primer 2. The coating thickness of the scraping coating is about: 4mm-5mm or design film 1 / 4 of the thickness, after the overall scrape coating is completed, place it in a workshop environment at about 25°C for 15 minutes;

[0030] Step 4: Repeat the third step to apply the second coat of fire retardant coating 3, and the coating thickness of the coat is about 4mm-5mm or 1 / 4 of the designed film thickness;

[0031] Step 5: After finishing the scra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com