Selective laser melting and forming method for TC4 titanium alloy hollowed-out artificial bone

A selective laser melting, titanium alloy technology, applied in the direction of additive manufacturing, process efficiency improvement, prosthesis, etc., can solve the problem of long time cycle in mold design and manufacturing, inability to realize, and difficult to realize the personalization and customization of bioartificial bone and other problems, to achieve the effect of improving biocompatibility, reducing weight, and uniform internal organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

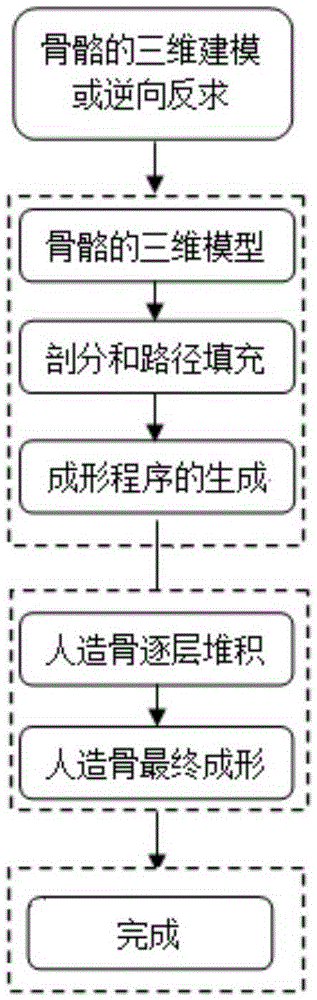

[0050] according to figure 1 As shown in the steps, the selective laser melting method of the TC4 titanium alloy artificial femur specifically includes the following steps:

[0051] (1) Design the CAD model of the TC4 titanium alloy artificial femur through the existing 3D modeling software; or use the traditional reverse method to obtain the 3D model of the TC4 titanium alloy artificial femur;

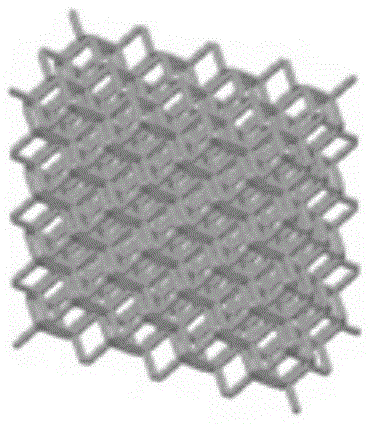

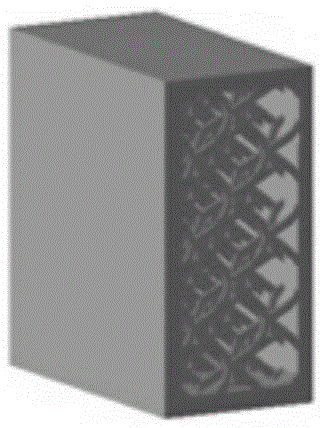

[0052] (2) Use commercial 3D design software to design the hollow structure of the 3D model of the artificial femur, select a suitable area to add the hollow grid structure, and increase the compatibility of the artificial femur with the human body;

[0053] (3) The artificial femur 3D model with a hollow structure is layered and discretized using commercial subdivision software, and the 3D model of the artificial femur is converted into a 2D slice model to obtain layer-by-layer cross-sectional contour data, and corresponding contour data are generated according to the contour data p...

Embodiment 2

[0063] according to figure 1 The steps shown, the selective laser melting method of the TC4 titanium alloy artificial pelvis, specifically includes the following steps:

[0064] (1) Design the CAD model of the TC4 titanium alloy artificial pelvis through the existing 3D modeling software; or use the traditional reverse method to obtain the 3D model of the TC4 titanium alloy artificial pelvis;

[0065] (2) Use commercial 3D design software to design the hollow structure of the 3D model of the artificial pelvis, select a suitable area to add the hollow grid structure, and increase the compatibility between the artificial pelvis and the human body;

[0066] (3) Use commercial subdivision software to carry out hierarchical discretization of the 3D model of the artificial pelvis, convert the 3D model of the artificial pelvis into a 2D slice model, obtain layer-by-layer cross-sectional contour data, and generate corresponding processing programs based on the contour data ;

[0067...

Embodiment 3

[0076] according to figure 1 The steps shown, the selective laser melting method of the TC4 titanium alloy artificial clavicle, specifically include the following steps:

[0077] (1) Design the CAD model of the TC4 titanium alloy artificial clavicle through the existing 3D modeling software; or use the traditional reverse method to obtain the 3D model of the TC4 titanium alloy artificial clavicle;

[0078] (2) Use commercial 3D design software to design the hollow structure of the 3D model of the artificial clavicle, select a suitable area to add the hollow grid structure, and increase the compatibility of the artificial clavicle with the human body;

[0079] (3) Use commercial subdivision software to carry out hierarchical discretization of the three-dimensional model of the artificial clavicle, convert the three-dimensional model of the artificial clavicle into a two-dimensional slice model, obtain layer-by-layer cross-sectional contour data, and generate corresponding proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com