Gear burr removing system with real-time monitoring function

A real-time monitoring and gear technology, which is applied to gear tooth manufacturing devices, belts/chains/gears, gear teeth, etc., to achieve the effects of ensuring meshing performance, high economic benefits, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

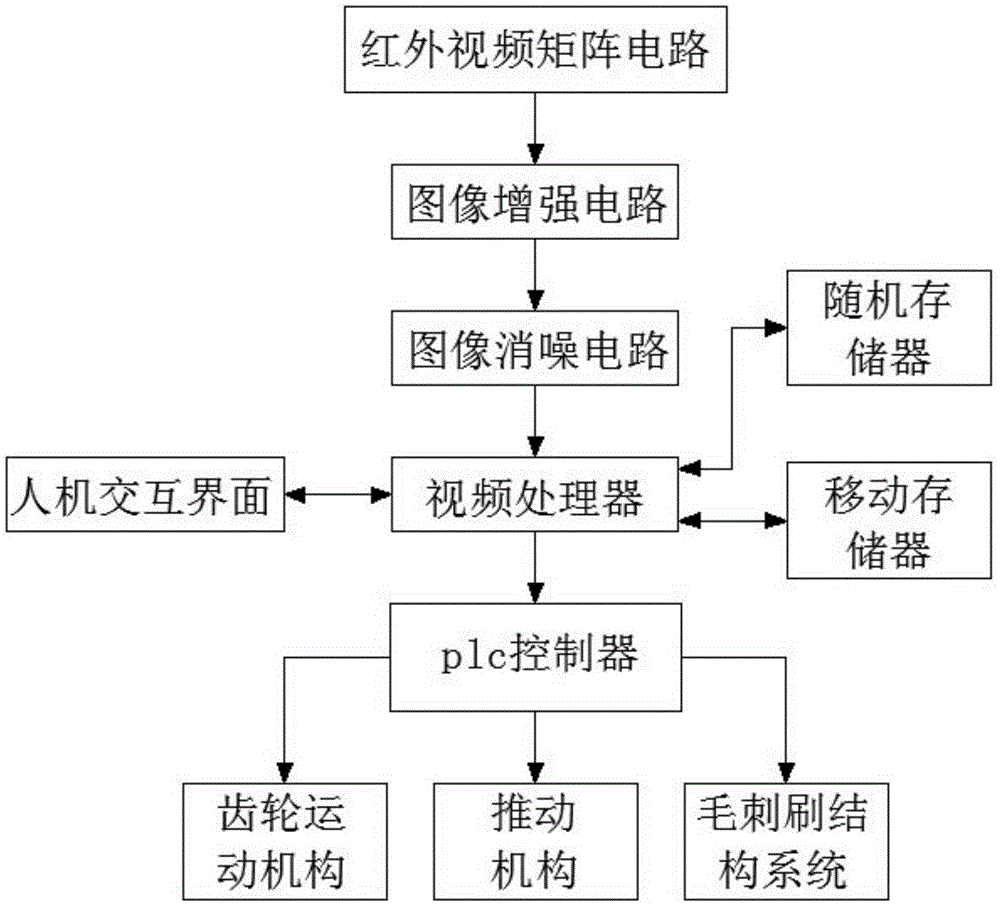

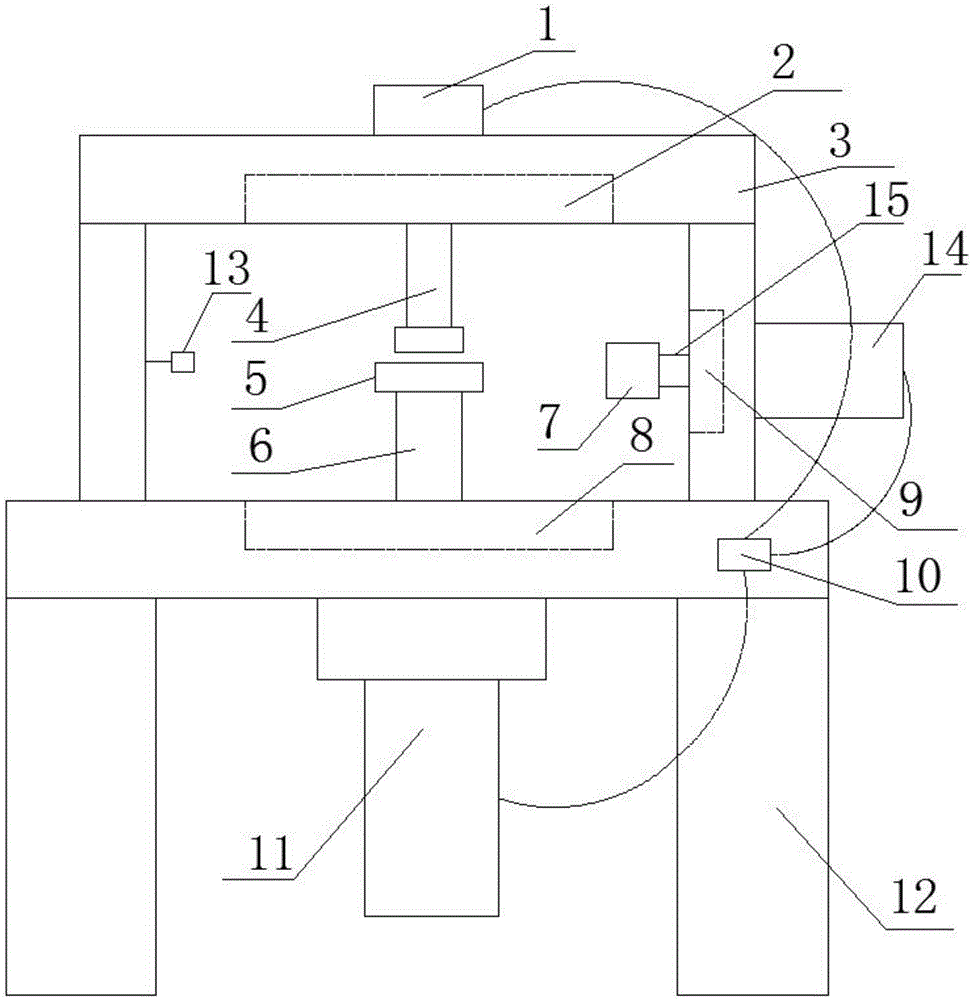

[0031] A system for deburring gears that can be monitored in real time. It can record the entire deburring process during gear surface deburring processing, and can record the gear image information extracted from the working process recording information in real time. Combining the comparison results of qualified gear image information preset in the video processor to formulate a new working strategy for the entire system, so as to achieve the purpose of automatic monitoring of gear deburring work, such as figure 1 , figure 2 As shown, the following structure is specially set up: including the system body and the control device 10 arranged on the system body, the system body is provided with an upper support system 3 and a lower support system 12, and the upper support system 3 is fixed on the lower part On the upper platform of the bracket system 12, the control device 10 is arranged on the lower bracket system 12; a gear movement mechanism 11 is arranged on the lower brack...

Embodiment 2

[0035] This embodiment is further optimized on the basis of the above-mentioned embodiments. In order to better realize the present invention, the gear to be deburred can be deburred by using the burr brush structure system under the cooperation of the gear movement mechanism and the pushing mechanism. ,Such as figure 1 , figure 2 As shown, the following structure is particularly provided: the rotating shaft 6 of the gear movement mechanism 11 runs through the upper table of the lower bracket system 12; the rotating shaft 4 of the pushing mechanism 1 runs through the upper table of the upper bracket system 3, and the rotating shaft 6 Coaxial with rotating shaft 4.

Embodiment 3

[0037] This embodiment is further optimized on the basis of any of the above-mentioned embodiments. Further, in order to better realize the present invention, the noise in the video signal after signal enhancement can be cleared so that the restored image is clearer, such as figure 1 , figure 2 As shown, the following structure is particularly provided: an image denoising circuit is also provided between the image enhancement circuit and the video processor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com