Flame preheating tungsten electrode argon arc brazing method

A tungsten argon arc and brazing method technology, applied in arc welding equipment, electric heating device, welding equipment and other directions, can solve the problems of affecting the wetting and filling of the solder, large thermal stress, difficult to use flux, etc. The effect of high brazing rate and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

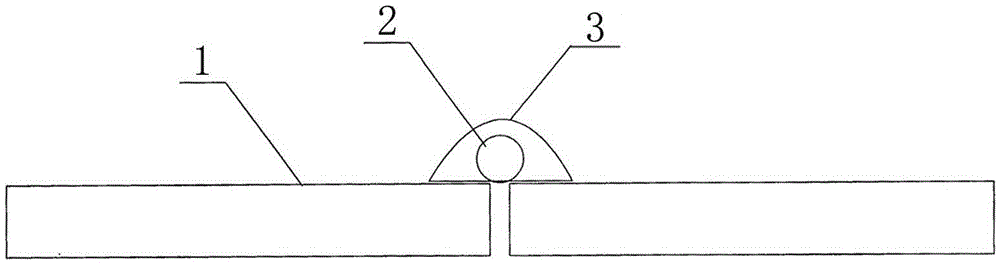

[0014] The 316LN austenitic stainless steel base metal 1 is butted, the base metal sample is 100mm long, 30mm wide, and 2mm thick. Ensure that the gap can be filled, and cover an appropriate amount of 101 flux 3 on the brazing seam and the solder 2, such as figure 1 shown.

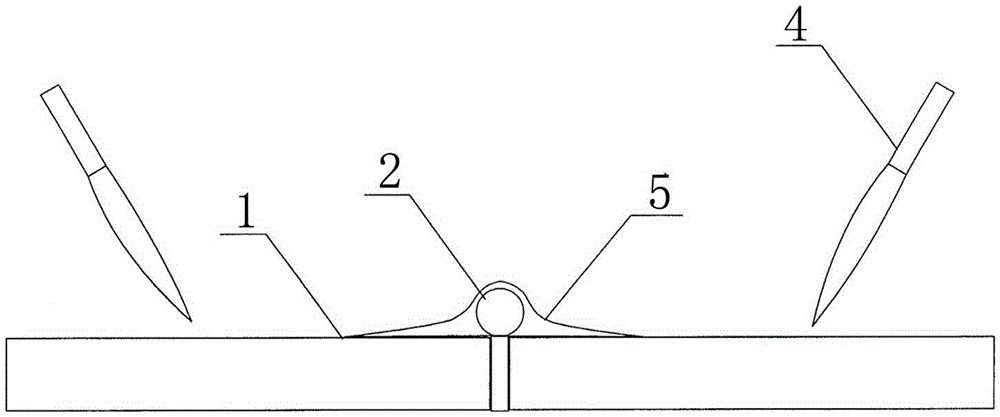

[0015] Use the flame gun 4 (hydrogen-oxygen flame gun can be selected) to preheat the surface of the base metal 1 that is far away from the brazing joint, and melt the 101 flux 3 through heat transfer, such as figure 2 shown.

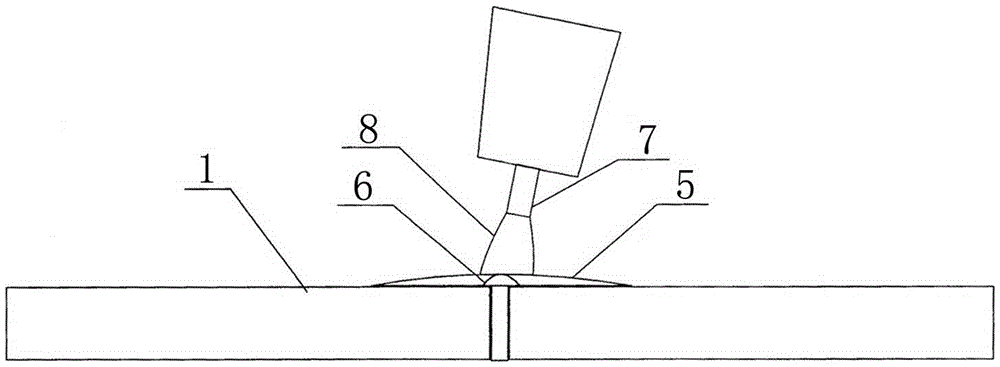

[0016] Under the protection of the molten flux 5, use the argon tungsten arc torch 7 to quickly heat the solder 2 to melt it through the discharge of the arc 8, and the liquid solder 6 fills the gap of the base metal 1, as image 3 shown.

[0017] During the cooling process, the base metal 1 is baked with a flame gun 4 to prevent excessive cooling, and after cooling, a brazing seam 9 is formed, such as Figure 4 shown.

[0018] The dimensions of the brazed joints were measure...

Embodiment 2

[0020] The 316LN austenitic stainless steel base metal 1 is butted, the base metal sample is 100mm long, 30mm wide, and 2mm thick, the width of the brazing seam is 0.15mm, and the Cu-Mn-Ni brazing material 2 is preset above the brazing seam. Ensure that the gap can be filled, and cover an appropriate amount of 201 flux 3 on the brazing seam and the solder 2, such as figure 1 shown.

[0021] Use the flame gun 4 (butane flame gun can be selected) to preheat the surface of the base metal 1 that is far away from the brazing joint, and melt the flux 3 through heat transfer, such as figure 2 shown.

[0022] Under the protection of the molten flux 5, use the argon tungsten arc torch 7 to quickly heat the solder 2 to melt it through the discharge of the arc 8, and the liquid solder 6 fills the gap of the base metal 1, as image 3 shown.

[0023] During the cooling process, the base metal 1 is baked with a flame gun 4 to prevent excessive cooling, and after cooling, a brazing seam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com