High-temperature-resistant and high-salt-resistant oil reservoir profile modifying water plugging agent and preparation method thereof

A profile control water shutoff agent, high temperature resistant technology, applied in the field of profile control water shutoff agent, oil reservoir profile control water shutoff agent, can solve the problem of restricting the application of particle plugging agent, damage to reservoir integrity, and particle plugging agent has not yet obtained the order Satisfactory effect and other issues, to achieve low-permeability reservoir damage, enhanced plugging effect, and stable bridge plugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

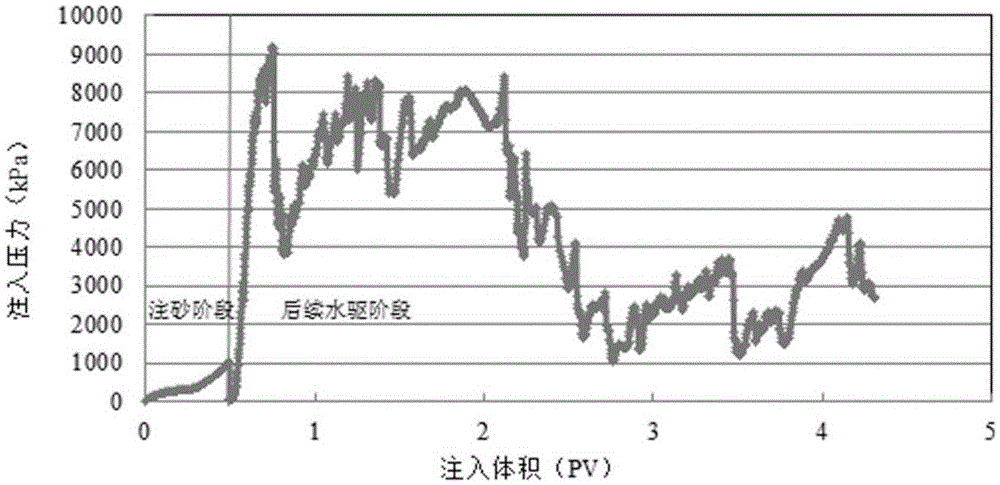

Image

Examples

Embodiment 1

[0038] This example provides a high-temperature and high-salt oil reservoir profile control and water shutoff agent, which is prepared by the following steps:

[0039]Dissolve the raw materials of the inner layer coating, and after high-temperature fluidized bed treatment, coat the inner layer coating on the surface of the inner core raw material. After the thickness reaches 8 μm (about 10 minutes), after drying and sieving, the outer layer The raw materials of the coating are dissolved, and the surface of the inner coating is coated with the outer coating. After the thickness reaches 4 μm, the coating is stopped (about 6 minutes). After drying and sieving, a bridging plugging agent with double coating is obtained. particles;

[0040] Dissolve 2g of guar gum powder in 400mL tap water, stir for 0.3h, add 20g of plugging agent particles (the core of the particle is silicon oxide, the inner layer is covered with a heat-swellable cross-linked resin film formed by acrylic resin, an...

Embodiment 2

[0052] This embodiment provides a high-temperature and high-salt oil reservoir profile control and water shutoff agent, based on the total amount of the high-temperature and high-salt oil reservoir profile control and water shutoff agent as 100wt%, which includes Blocking agent particles (the inner core of the particle is silicon oxide, the inner film is a heat-swellable cross-linked resin film formed by acrylic resin, and the outer film is a rigid resin protective film formed by phenolic resin), 0.5wt% guar gum, 0.1 wt% sodium borate and the balance water. It is prepared according to the preparation method of Example 1.

[0053] BROOKFIELD rotary viscometer DV-II+ was used to measure the variation curve of the viscosity of the profile control and water shutoff agent for high-temperature and high-salt oil reservoirs of this embodiment as a function of temperature. The measurement results are shown in Table 1.

[0054] Table 1

[0055] temperature / ℃

Embodiment 3

[0057] This embodiment provides a high-temperature and high-salt oil reservoir profile control and water shutoff agent, based on the total amount of the high-temperature and high-salt oil reservoir profile control and water shutoff agent as 100wt%, which includes Blocking agent particles (the core of the particle is calcite, the inner layer is coated with a heat-swellable cross-linked resin film formed by alkyd resin, and the outer layer is coated with a rigid resin protective film formed by epoxy resin), 0.5wt% guar gum , 0.1wt% sodium borate and the rest of the water. It is prepared according to the preparation method of Example 1.

[0058] BROOKFIELD rotational viscometer DV-II+ was used to measure the variation curve of viscosity with temperature of the profile control and water shutoff agent for high-temperature and high-salt oil reservoirs in this example after standing for 30 hours. The measurement results are shown in Table 2.

[0059] Table 2

[0060] tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com