As-cast malleable cast iron cylinder sleeve produced through centrifugal casting and production process of as-cast malleable cast iron cylinder sleeve

A technology of centrifugal casting and production process, applied in the field of cylinder liner, can solve the problems of inability to meet the production requirements of energy saving and environmental protection cylinder liner, high scrap rate, complex casting process, etc., and achieves low cost, short production cycle, elongation and resistance. The effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

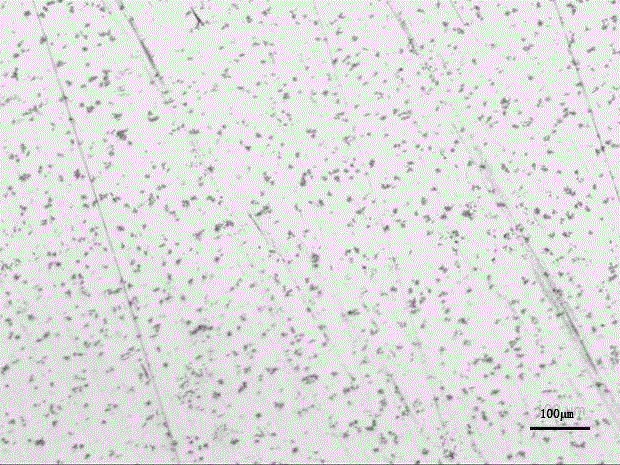

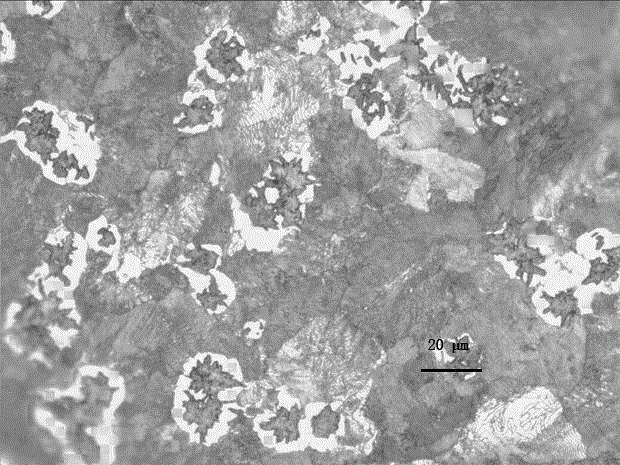

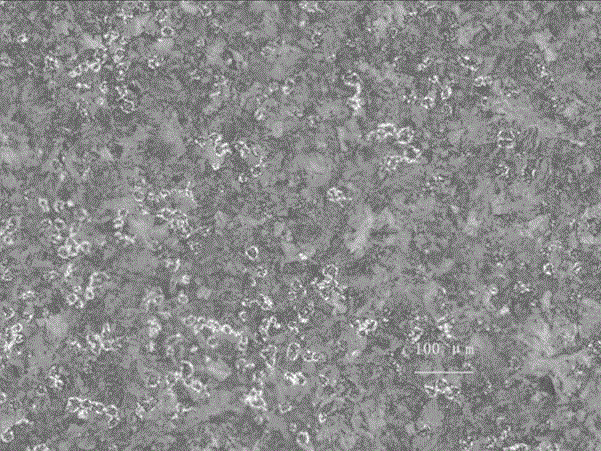

Image

Examples

Embodiment 1

[0018] A kind of as-cast malleable cast iron cylinder liner produced by centrifugal casting, in terms of weight percentage, its material chemical composition is:

[0019]

[0020] The production method of the as-cast malleable cast iron cylinder liner produced by above-mentioned centrifugal casting comprises the following steps:

[0021] 1) Ingredients and smelting: smelting in a 500kg intermediate frequency induction furnace, weighing 0.5% of the total mass of raw materials except Ce, Bi and Al and smelting raw materials in proportion to silicon carbide (carbon content 40% ~ 45%, silicon content 55% ~ 60%, particle size 1 ~ 2mm) to prepare raw materials, and then melted into molten iron in a 500kg intermediate frequency induction furnace, the melting temperature is 1470 ° C; A mixture of Ce and Bi (silicon carbide particle size 0.5-1mm);

[0022] 2) Casting: Cylinder liner castings are produced by water-cooled metal-type wet paint centrifugal casting process. The casting ...

Embodiment 2

[0026] A kind of as-cast malleable cast iron cylinder liner produced by centrifugal casting, in terms of weight percentage, its material chemical composition is:

[0027]

[0028] The production method of the as-cast malleable cast iron cylinder liner produced by above-mentioned centrifugal casting, it comprises the steps:

[0029] 1) Ingredients and smelting: smelting in a 500kg intermediate frequency induction furnace, weighing 3% of the total mass of raw materials except Ce, Bi and Al and smelting raw materials in proportion to silicon carbide (carbon content 40% to 45%, silicon content 55% to 60%, particle size 1-2mm) to prepare raw materials, and then smelt it into molten iron in a 500kg medium-frequency induction furnace at a melting temperature of 1520°C; Mixture with Bi (silicon carbide particle size 0.5 ~ 1mm);

[0030] 2) Casting: Cylinder liner castings are produced by water-cooled metal type wet paint centrifugal casting process, the casting temperature is 1460...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com