Burdock leaf stripping and spirally-conveying machine

A technology of rotary leaf machine and burdock, which is applied to excavators, harvesters, excavating harvesters, etc., can solve the problems of labor, affecting the harvest of burdock, time-consuming, etc., and achieve the effects of simple structure, high degree of automation, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

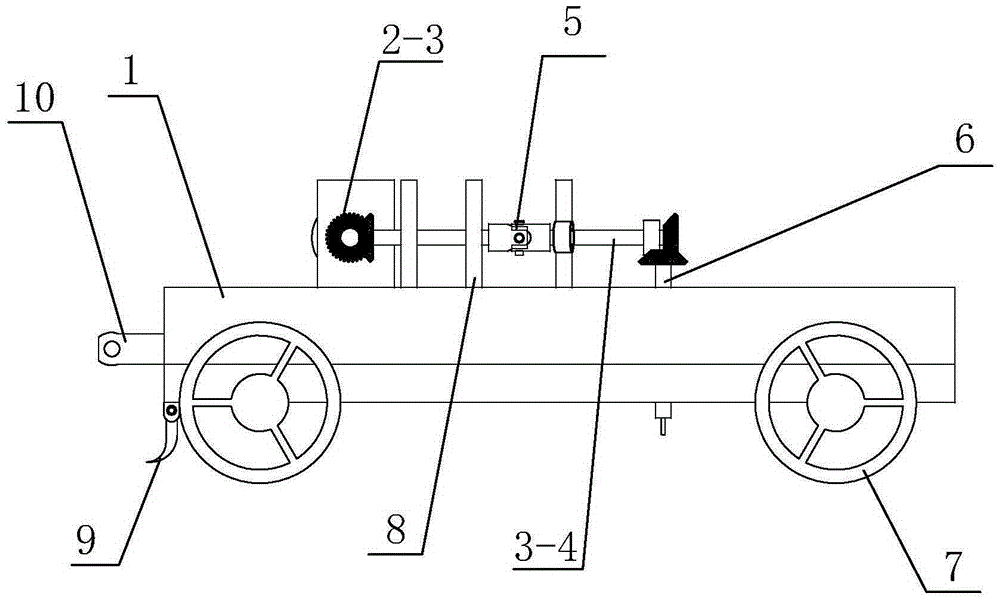

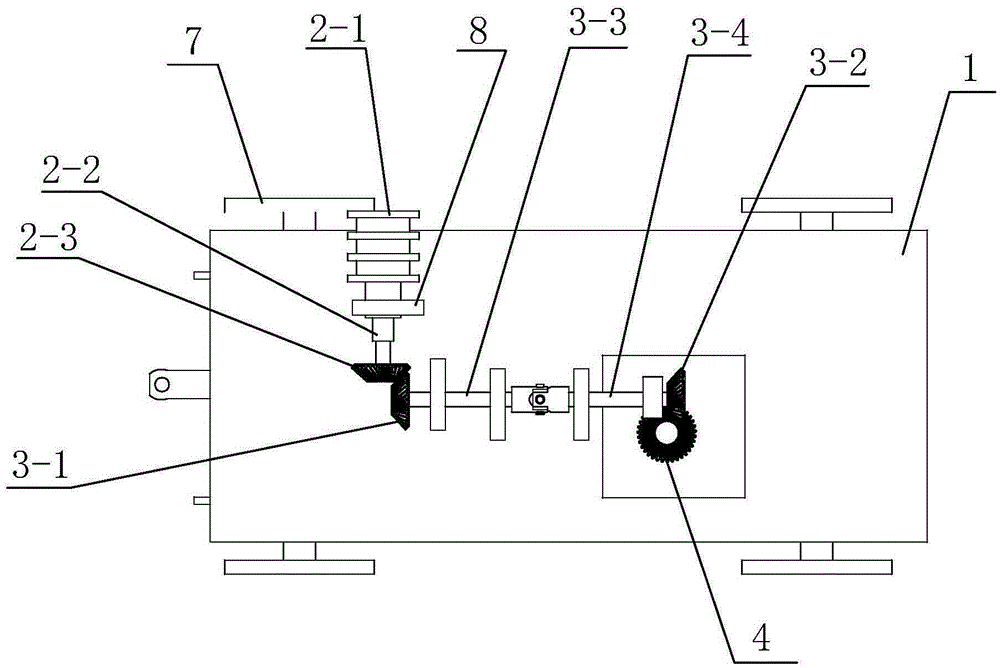

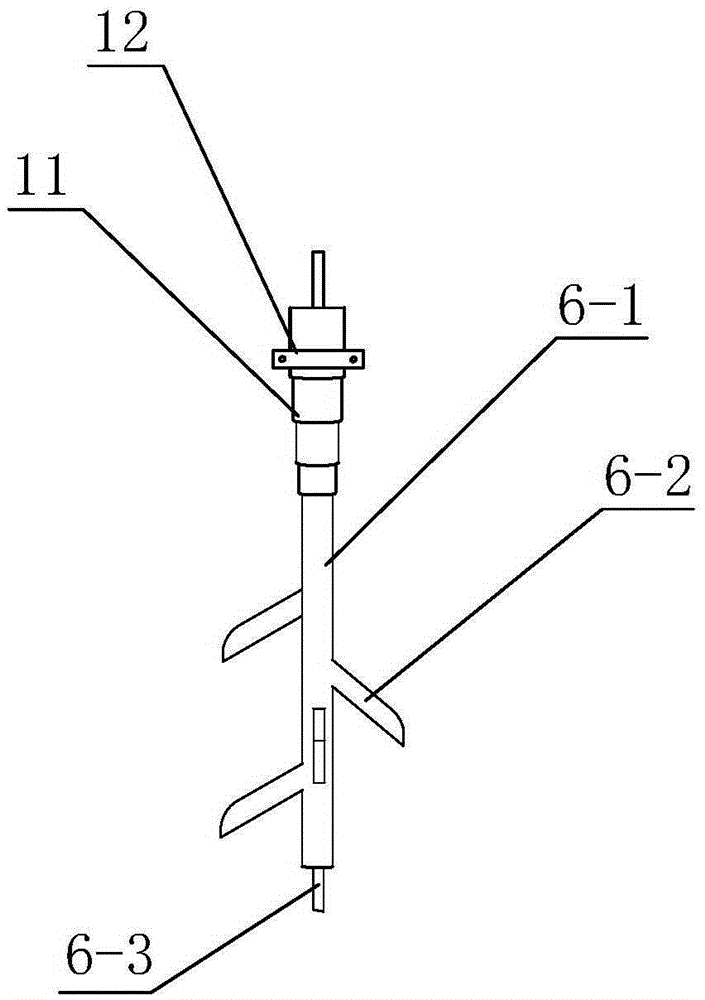

[0023] Such as figure 1 , figure 2 Shown, a kind of burdock rotary machine, comprises car body 1 and the wheel 7 that is installed on the bottom of car body 1, also comprises the belt transmission mechanism that is installed on the top casing of car body 1, transmission system and executive system, wherein

[0024] The belt transmission mechanism includes a pulley 2-1, a stepped shaft 2-2 and a first gear 2-3, the pulley 2-1 is connected with one of the wheels 7, and uses the wheel 7 as a driving pulley to provide power, so The stepped shaft 2-2 is installed on the car body 1 through the bearing seat 8, and the input end of the stepped shaft 2-2 is connected with the center line shaft of the pulley 2-1, and its output end is connected with the first gear 2-3;

[0025] The transmission sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com