Compound pendulum type roller mill

A roller mill and frame technology, applied in the field of ore crushing and grinding equipment, can solve the problems of low grinding efficiency, left and right slippage, and small contact area, so as to improve utilization rate, improve grinding efficiency, and increase contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

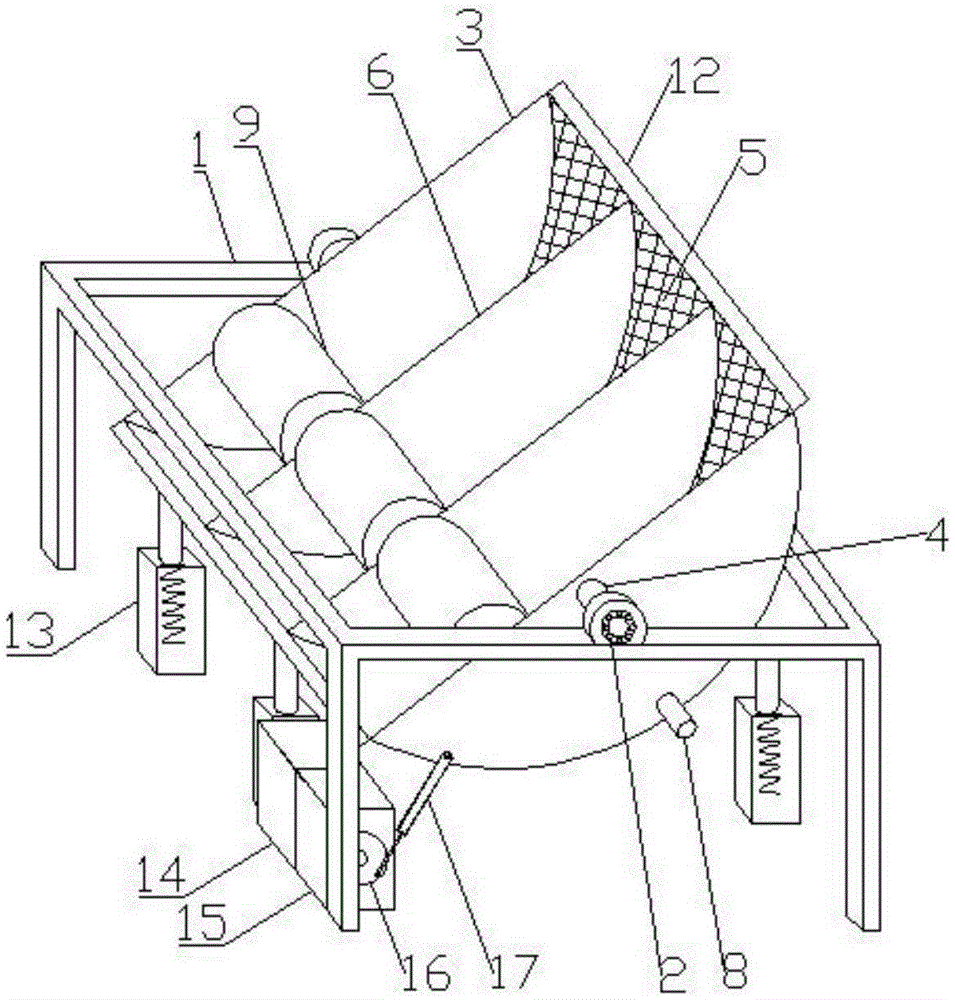

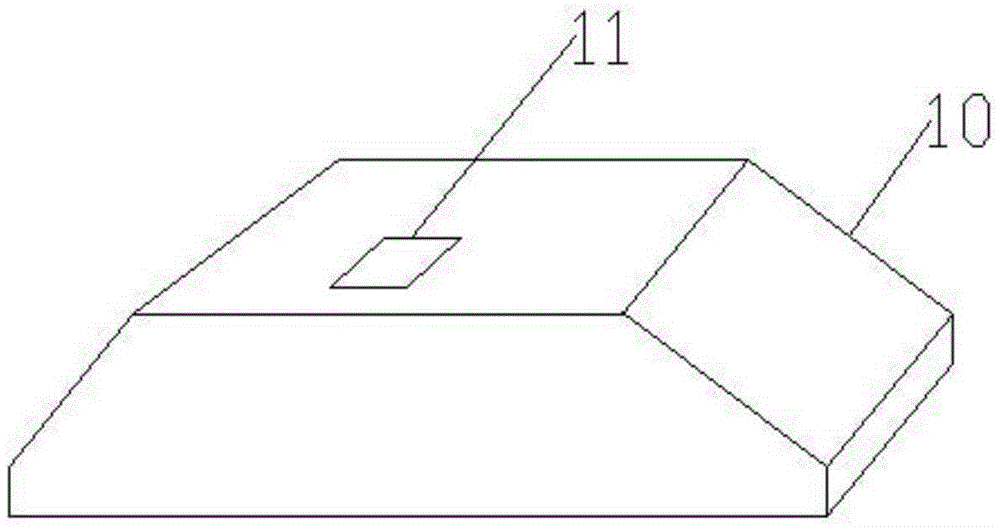

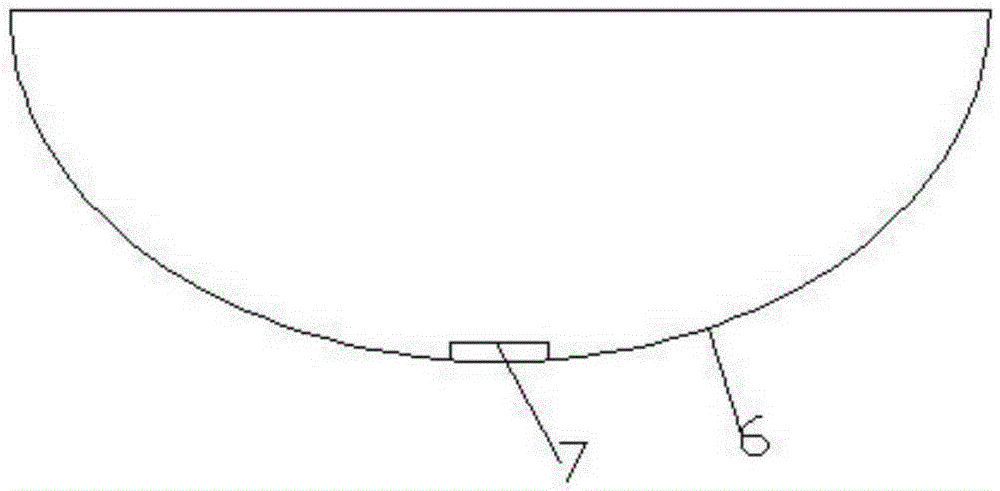

[0022] As shown in the figure, a compound pendulum type roller mill includes a frame 1, bearings 2 are respectively installed at both axial ends of the frame 1, a swing box 3 is arranged on the frame 1, and a swing box 3 is installed on the frame 1. The load-bearing centers at both ends of the axial direction are respectively provided with a load-bearing center shaft 4, and the load-bearing center shafts 4 are respectively installed in the corresponding bearings 2. The bottom plate of the swing box 3 is arc-shaped, and the inner bottom surface of the swing box 3 bottom plate is installed. The liner 5 is provided with a plurality of partitions 6 in the axial direction on the inner wall of the swing box 3, and the partitions 6 divide the inside of the swing box 3 into a plurality of tumbling chambers, and each partition 6 is provided at the bottom. There is a material opening 7, and a discharge opening 8 is provided at the bottom of the end plate of the swing box 3. Rollers 9 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com