Metal injection molding (MIM) powder mixing-pressing apparatus and process thereof

A powder injection molding and powder technology, applied in the field of powder metallurgy, can solve the problems of uneven mixing of metal powder and plasticizer, uniformity of gap cracks, uneven density distribution of injection products, etc. The effect of less surface cracks, cracks and cell reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

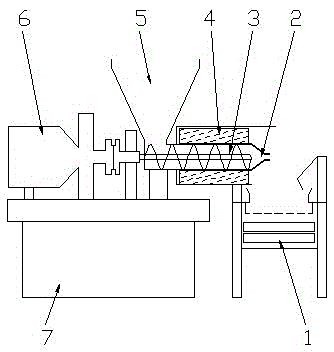

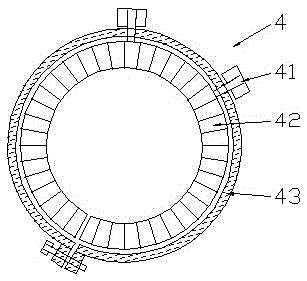

[0017] The powder injection molding (MIM) powder mixing and pressing equipment described in the present invention includes a pressing roller 1 and a feeding mechanism, and the feeding mechanism includes a conical discharge port 2, a screw pusher 3, a heating device 4 and a feed port 5 , the conical discharge port 2 of the feeding mechanism is located above the pressing surface roller 1, and a heating device 4 is installed on the outer side of the conveyance path of the screw propeller 3, and the two ends of the screw propeller 3 are connected with the feed port 5 and the conical discharge port respectively. Port 2 communicates, the screw rod of the screw propeller 3 is connected to the screw propeller driving motor 6, and the screw propeller 3 and the screw propeller driving motor 6 are fixedly installed above the power distribution control cabinet 7; the heating device 4 includes a heating supply electrode 41, The heating resistor section 42 and the reinforcing collar 43 are d...

Embodiment 2

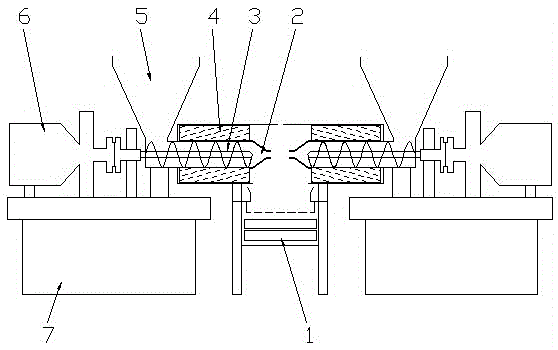

[0020] The powder injection molding (MIM) powder mixing and pressing equipment described in Example 1 is different in that: the feeding mechanism is distributed in pairs on both sides of the pressing roller 1, and the two feeding mechanisms share one pressing roller 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com