A high-precision CNC cylindrical milling machine

A circular milling machine, high-precision technology, applied in the field of high-precision CNC cylindrical milling machines, can solve the problems of lack of rigidity of machine tools, increased maintenance frequency of CNC lathes, and inapplicability to large crankshafts, etc., to achieve good product adaptability, low cost, and processing. Accurate and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

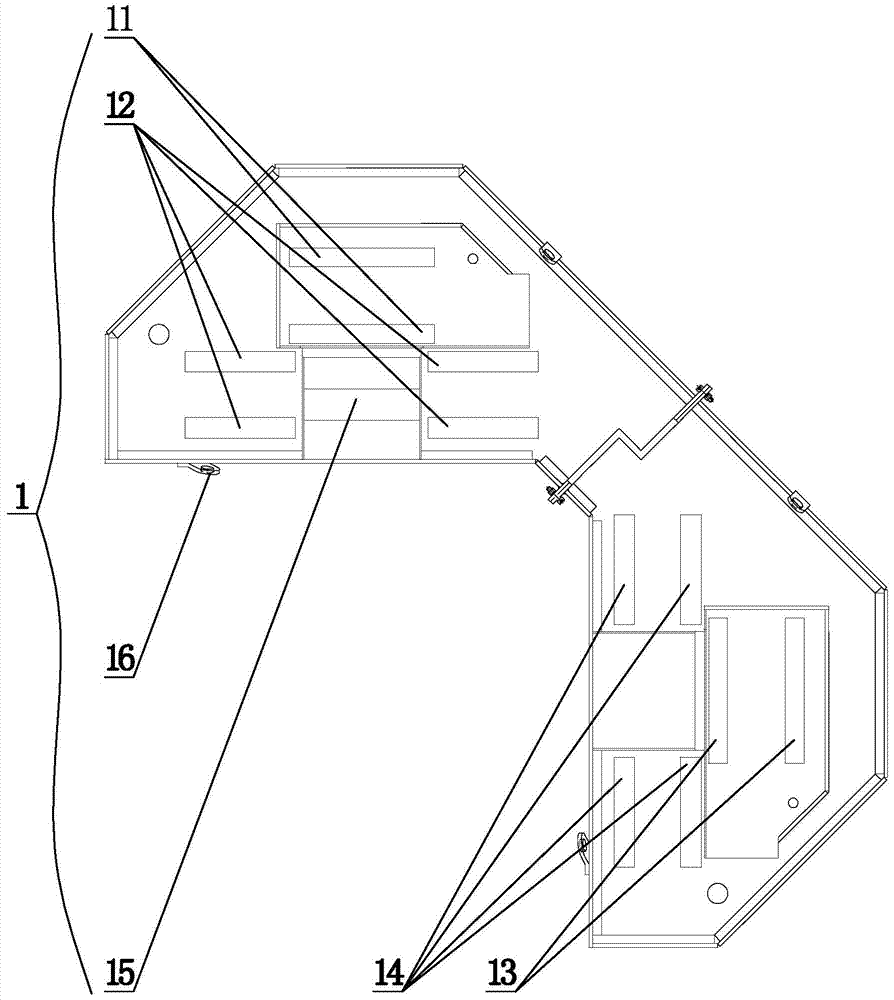

[0031] In this embodiment, a high-precision numerically controlled cylindrical milling machine is combined with figure 1 , including bed 1 and machine tool, combined with figure 1 , the bed 1 is 7-shaped, and the bed 1 is provided with a backing plate 11, a backing plate 2 12, a backing plate 3 13, a backing plate 4 14 and a V-shaped slope 15; there are a backing plate 11, a backing plate 2 12 1. One end where the V-shaped inclined plane 15 is located is a four-rod journal processing station 1a, and the other end of the bed is the backing plate three 13, and the end where the backing plate four 14 is located is two or three connecting rod journal processing stations 1b.

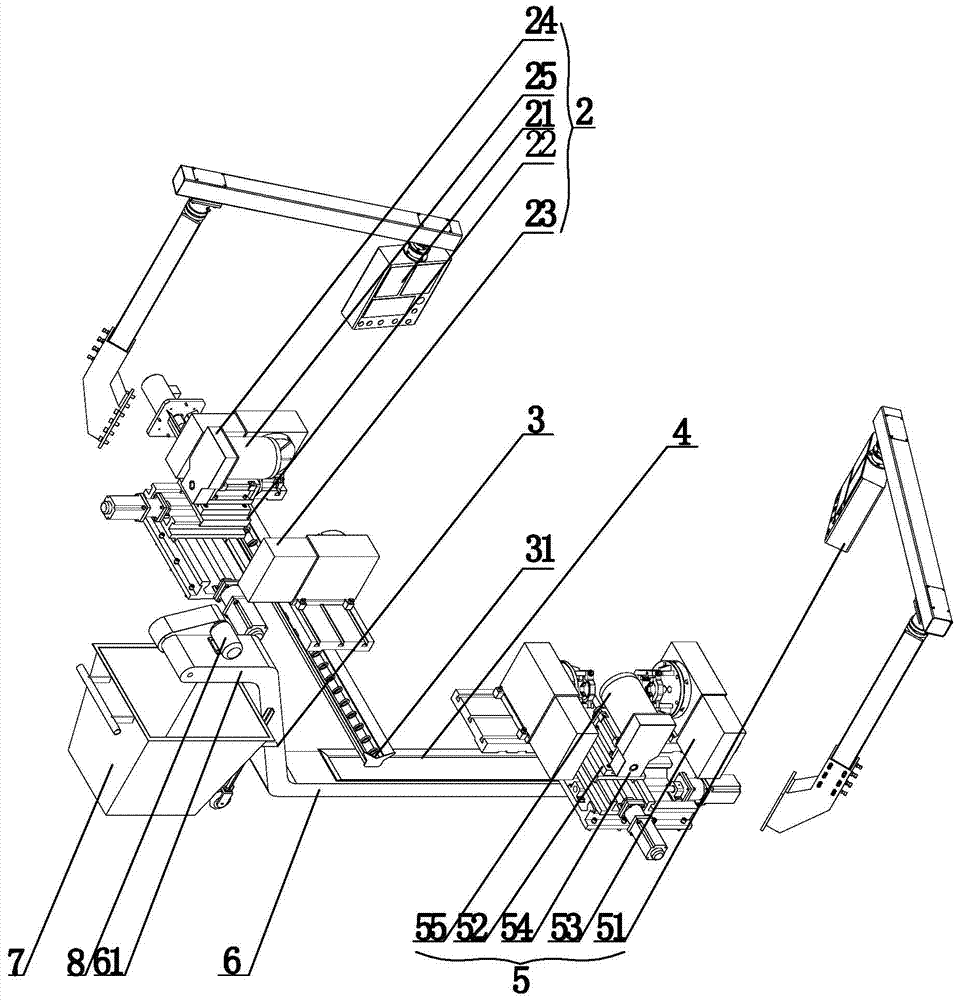

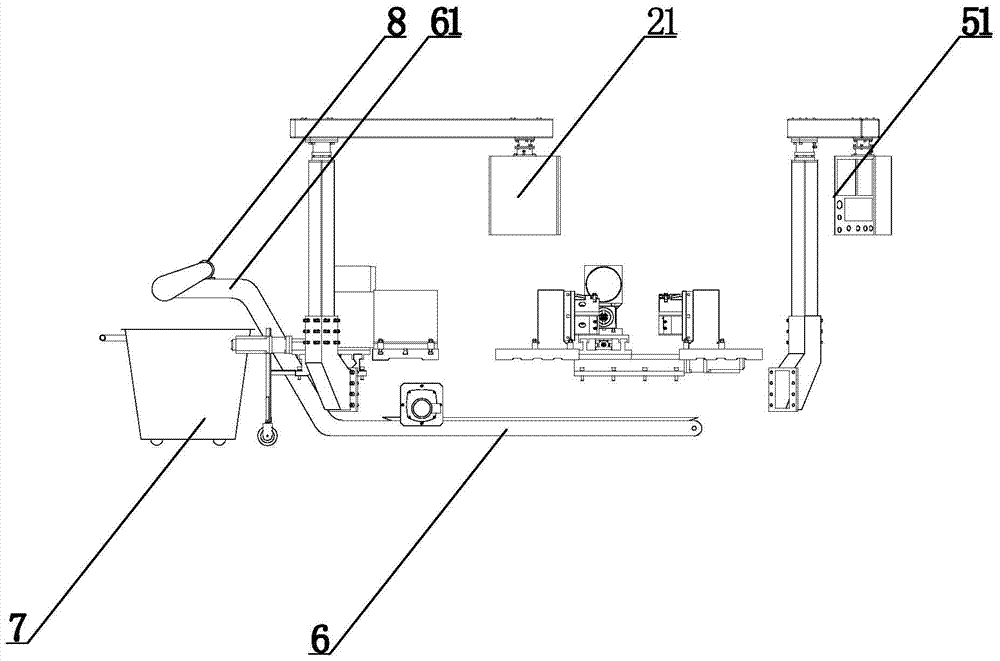

[0032] The machine tool is installed on the bed, combined with figure 2 , image 3 and Figure 4 , The machine tool includes A unit 2, spiral chip conveyor 3, flat chip conveyor 4 and B unit 5.

[0033]Among them, the A unit 2 includes a numerical control panel 1 21, a cross slide 22 and a rotary center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com