Modified asphalt waterproof coiled material as well as structure and construction technology thereof

A technology for modifying asphalt and waterproofing membranes. It is used in asphalt layered products, tools for roof engineering, building structures, etc. It can solve the problem of low tensile strength of asphalt membranes, poor integrity of the waterproof layer, and the incidence of leakage. Advanced problems, to avoid the hot melt method, strong integrity, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

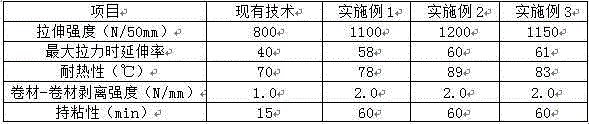

[0047] Embodiment 1 A kind of modified asphalt waterproof membrane

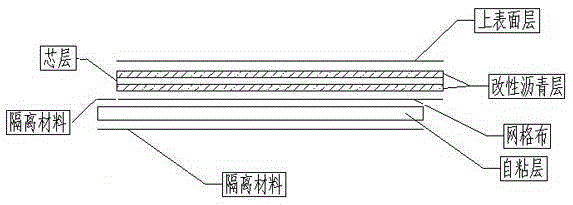

[0048] The modified asphalt waterproof membrane: including an upper surface layer, a modified asphalt layer, a core layer, a glass fiber mesh cloth, a self-adhesive layer, and an isolation film;

[0049] The raw materials of the modified asphalt waterproof membrane include: asphalt, SBS or APP modifier, softening oil, filler, polyester tire, grid cloth, and PE film.

[0050] 1. The formula of the modified asphalt layer, in parts by weight:

[0051] 45 parts of base asphalt, 2 parts of modifier, 2 parts of softening oil, 2 parts of reinforcing agent, 4 parts of recycled epoxy resin powder, 15 parts of inorganic filler, 4 parts of elastic particles;

[0052] The base asphalt is: No. 70 asphalt;

[0053] Described softening oil is: minus second-line oil;

[0054] The modifier: SBS elastomer;

[0055] The reinforcing agent: it is wollastonite needle crystal fiber with a particle size of 100-500 mesh and an av...

Embodiment 2

[0070] Embodiment 2 A kind of modified asphalt waterproof membrane

[0071] The modified asphalt waterproof membrane: including an upper surface layer, a modified asphalt layer, a core layer, a glass fiber mesh cloth, a self-adhesive layer, and an isolation film;

[0072] 1. The formula of the modified asphalt layer, in parts by weight:

[0073] 55 parts of base asphalt, 8 parts of modifier, 12 parts of softening oil, 10 parts of reinforcing agent, 6 parts of recycled epoxy resin powder, 22 parts of inorganic filler, 6 parts of elastic particles;

[0074] The base asphalt is: No. 90 asphalt;

[0075] Described softening oil is: be machine oil;

[0076] The modifier: is APP plastomer;

[0077] The reinforcing agent: calcium sulfate needle-like fibers with a particle size of 100-500 mesh and an average aspect ratio of 5-15;

[0078] The regenerated epoxy resin powder: fineness requirement: 80-325 mesh;

[0079] The inorganic filler is: 80-200 mesh talcum powder;

[0080] T...

Embodiment 3

[0091] Embodiment 3 A kind of modified asphalt waterproof membrane

[0092] The modified asphalt waterproof membrane: including an upper surface layer, a modified asphalt layer, a core layer, a glass fiber mesh cloth, a self-adhesive layer, and an isolation film;

[0093] 1. The formula of the modified asphalt layer, in parts by weight:

[0094] 70 parts of base asphalt, 15 parts of modifier, 18 parts of softening oil, 15 parts of reinforcing agent, 10 parts of recycled epoxy resin powder, 30 parts of inorganic filler, 10 parts of elastic particles;

[0095] The base asphalt is: No. 100 asphalt;

[0096] Described softening oil is: minus second-line oil;

[0097] The modifier: SBS elastomer;

[0098] The reinforcing agent: Wollastonite needle-like crystal fibers with a particle size of 100-500 mesh and an average aspect ratio of 5-15;

[0099] The regenerated epoxy resin powder: fineness requirement: 80-325 mesh;

[0100] The inorganic filler is: 80-200 mesh talcum powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com