Machine for integrating constructing, cleaning and maintaining of hanger rail type external wall

A rail-mounted, maintenance machine technology, applied in cleaning equipment, window cleaning, lifting devices, etc., can solve the problems of high safety risk, heavy machine, large overturning moment, etc., to increase the coverage area, increase the work area, The effect of reducing the overturning moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

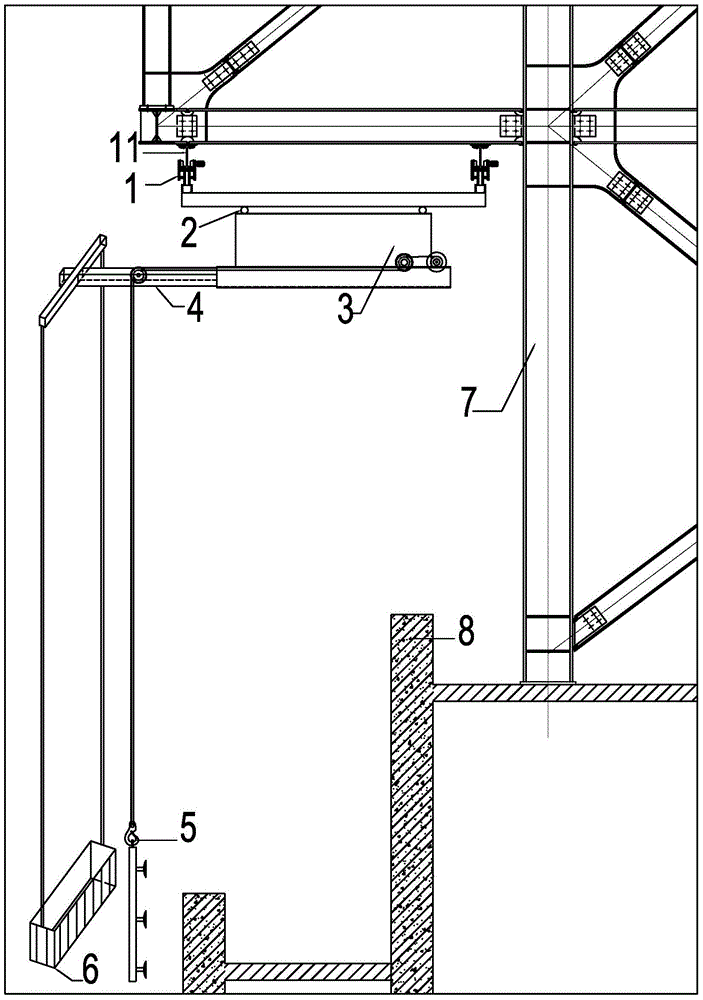

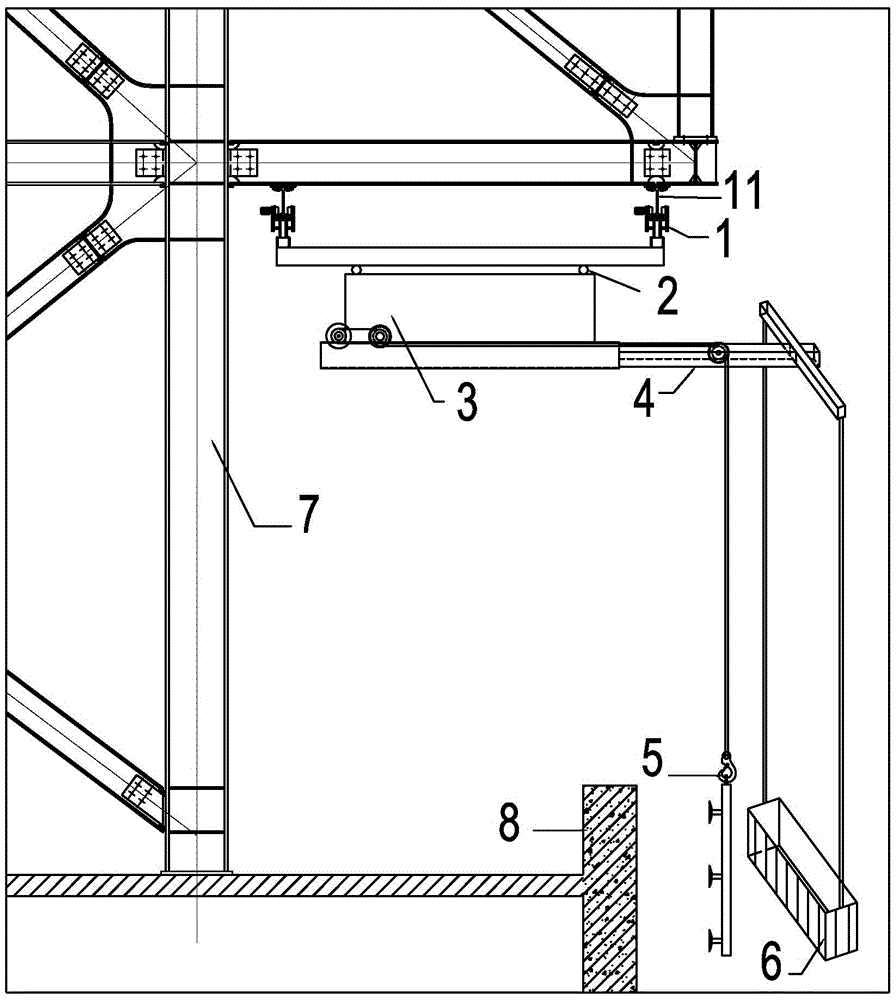

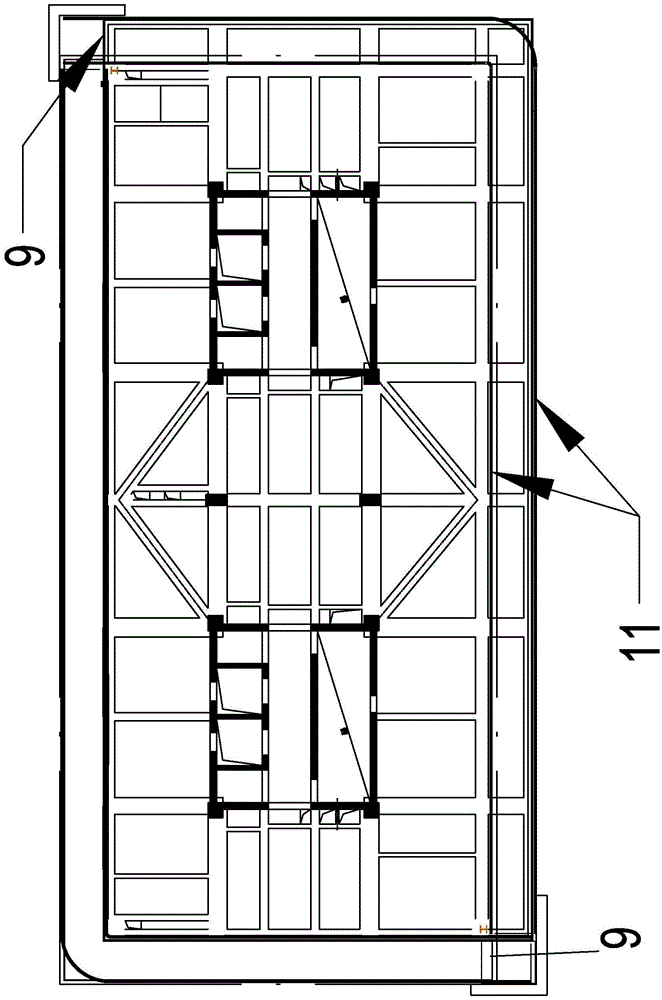

[0070] Such as Figure 1 to Figure 5 As shown, the hanging track 11 in the integrated hanging track type exterior wall construction, cleaning and maintenance machine provided by the present invention is two I-shaped steel tracks parallel to each other, which are fixed on the top surface of the building main body with the eaves facing downwards. Steel structure 7 on. It is located above the roof parapet 8 of the main structure and is set around the building, such as image 3 As shown, two sets of suspension rails are arranged around the perimeter of the building with a rectangular section, and each set is arranged on two adjacent sides. The traveling frame 12 is a frame with a rectangular cross section, and the traveling frame 12 is arranged on the hanging track 11 by the traveling machine 1, specifically, the hanging lug 12a is set on the walking frame 12, and the hanging lug 12a A connecting shaft is provided on the top to connect the traveling wheel fixing plate of the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com