High-refraction-rate resin and application thereof

A high refractive index, resin technology, applied in the field of optoelectronic display, can solve the problems of easy aging, thermal and optical instability of organic resins, limited increase in the refractive index of materials, etc., to improve photothermal stability, achieve long-term storage, and eliminate Effects of halogen residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

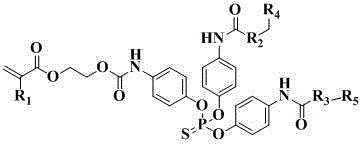

[0028] Embodiment 1: Synthetic preparation of high refractive index resin

[0029]

[0030] In a four-neck flask equipped with mechanical stirring, heating, reflux condensation and constant pressure dropping funnel, add 46.5g (0.1mol) triphenylisocyanate and butyl acetate respectively, gradually heat up to 50 degrees, drop 11.6g (0.1mol) of hydroxyethyl acrylate, after the dropwise addition, the reaction was continued for 2 hours. Then a butyl acetate solution containing 18.8 g (0.2 mol) of phenol was added dropwise, and the progress of the reaction was monitored by thin-layer chromatography. When the composition of the reactant system is basically unchanged, the temperature is lowered to stop the reaction. After filtration, the solvent was removed under reduced pressure, and the product was obtained after purification with a yield of 83%.

[0031] Tested with BrukeAV400 superconducting nuclear magnetic resonance spectrometer, the results are as follows:

[0032] 1 HNMR...

Embodiment 2

[0036] Embodiment 2: the synthetic preparation of compound M2

[0037]

[0038] In a four-neck flask equipped with mechanical stirring, heating, reflux condensation and constant pressure dropping funnel, add 46.5g (0.1mol) triphenylisocyanate and butyl acetate respectively, gradually heat up to 50 degrees, drop 13.0 g (0.1 mol) of hydroxyethyl methacrylate, after the dropwise addition, the reaction was continued for 2 hours. Then a butyl acetate solution containing 18.8 g (0.2 mol) of phenol was added dropwise, and the progress of the reaction was monitored by thin-layer chromatography. When the composition of the reactant system is basically unchanged, the temperature is lowered to stop the reaction. After filtration, the solvent was removed under reduced pressure, and the product was obtained after purification with a yield of 89%.

[0039] Tested with BrukeAV400 superconducting nuclear magnetic resonance spectrometer, the results are as follows:

[0040] 1 HNMR (400M...

Embodiment 3

[0044] Embodiment 3: the synthetic preparation of compound M3

[0045]

[0046] In a four-neck flask equipped with mechanical stirring, heating, reflux condensation and constant pressure dropping funnel, add 46.5g (0.1mol) triphenylisocyanate and butyl acetate respectively, gradually heat up to 50 degrees, drop 11.6g (0.1mol) of hydroxyethyl acrylate, after the dropwise addition, the reaction was continued for 2 hours. Then a butyl acetate solution containing 22.2 g (0.2 mol) of mercaptophenol was added dropwise, and the progress of the reaction was monitored by thin-layer chromatography. When the composition of the reactant system is basically unchanged, the temperature is lowered to stop the reaction. After filtration, the solvent was removed under reduced pressure, and the product was obtained after purification with a yield of 83%.

[0047] Tested with BrukeAV400 superconducting nuclear magnetic resonance spectrometer, the results are as follows:

[0048] 1 HNMR (40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com