Manufacturing method of heat preservation material with excellent fireproof performance

A technology of thermal insulation material and manufacturing method, which can be used in fire-resistant coatings, coatings, etc., and can solve the problems of easy adhesion, easy volatilization of methanol and ethylene glycol, and inability to combine curing and molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

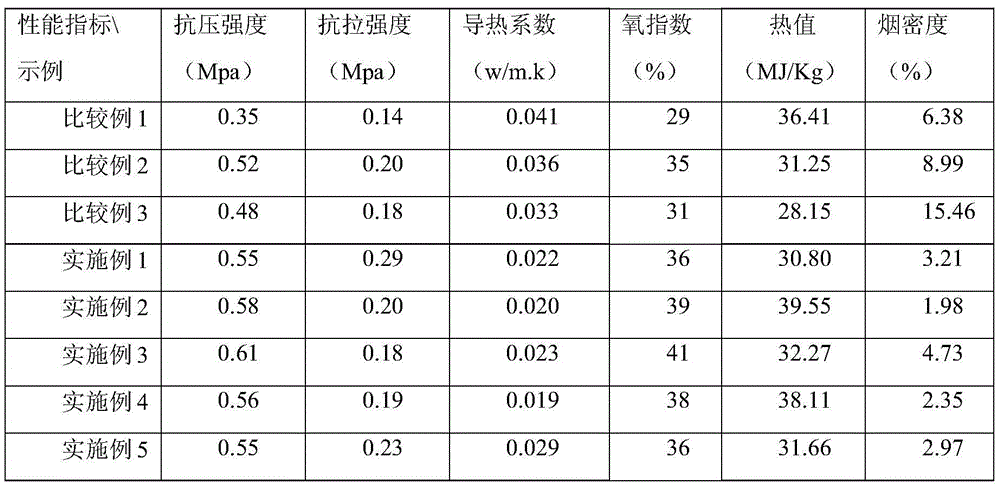

Examples

Embodiment 1

[0061] The manufacture method of the flame retardant insulation board of this embodiment is as follows:

[0062] One, prepare graphene, comprise the steps:

[0063](1) Preparation of expanded graphite. Among them, graphite oxide is firstly placed in a crucible, then the muffle furnace is heated to a certain temperature, the crucible is put into the muffle furnace and kept for a certain period of time, and then the crucible is taken out to obtain expanded graphite. Wherein, the heating rate of the heating muffle furnace is 10° C. / min, the muffle furnace is heated to 1000° C., and the holding time of the crucible in the muffle furnace is 3 minutes.

[0064] (2) Dispersing expanded graphite in water, adding polystyrene pellet water dispersion and ultrasonication to obtain expanded graphite-polystyrene composite dispersion; wherein, the mass ratio of expanded graphite to water is 1:2, and expanded graphite The mass ratio to the polystyrene pellet water dispersion is 60:1, and th...

Embodiment 2

[0081] The manufacture method of the flame retardant insulation board of the present embodiment is as follows:

[0082] One, prepare graphene, comprise the steps:

[0083] (1) Put the graphite oxide in the crucible, heat the muffle furnace to 1100°C, and the heating rate is 15°C / min, put the crucible into the muffle furnace and keep it warm for 5 minutes, then take out the crucible to obtain expanded graphite.

[0084] (2) Disperse expanded graphite in water, the mass ratio of expanded graphite to water is 1:2, add polystyrene pellet water dispersion, the mass ratio of expanded graphite to polystyrene pellet water dispersion is 70:1 , sonicated for 2h to prepare expanded graphite-polystyrene composite dispersion;

[0085] (3) Suction filter the expanded graphite-polystyrene composite dispersion onto the nickel foam, dry at a drying temperature of 60°C, and dry for 12 hours, place the foamed nickel loaded with expanded graphite-polystyrene in a mixture of hydrazine hydrate and...

Embodiment 3

[0101] The manufacture method of the flame retardant insulation board of this embodiment is as follows:

[0102] One, prepare graphene, comprise the steps:

[0103] (1) Put graphite oxide in a crucible, then heat the muffle furnace to 1100°C at a heating rate of 12°C / min, put the crucible into the muffle furnace and keep it warm for 4 minutes, then take out the crucible to obtain expanded graphite.

[0104] (2) Disperse expanded graphite in water, the mass ratio of expanded graphite to water is 1:2, add polystyrene pellet water dispersion, the mass ratio of expanded graphite to polystyrene pellet water dispersion is 70:1 , sonicated for 2h to prepare expanded graphite-polystyrene composite dispersion;

[0105] (3) Suction filter the expanded graphite-polystyrene composite dispersion onto the foamed nickel, the speed of suction filtration is 4L / s, dry, the drying temperature is 60°C, and the drying time is 11h, the expanded graphite-polystyrene is loaded Nickel foam reacts in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com