Thermosetting resin composition, prepreg containing same, laminated board and printed circuit board

A technology of resin composition and printed circuit board, which is applied in the field of thermosetting resin composition, prepreg, laminate and printed circuit board, which can solve the problem of thermal conductivity of thermally conductive fillers, difficulty in forming thermal conduction paths, and difficult high Thermal conductivity and other issues to achieve the effect of improving poor thermal conductivity, good thermal conductivity, and improving the thermal conductivity of the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

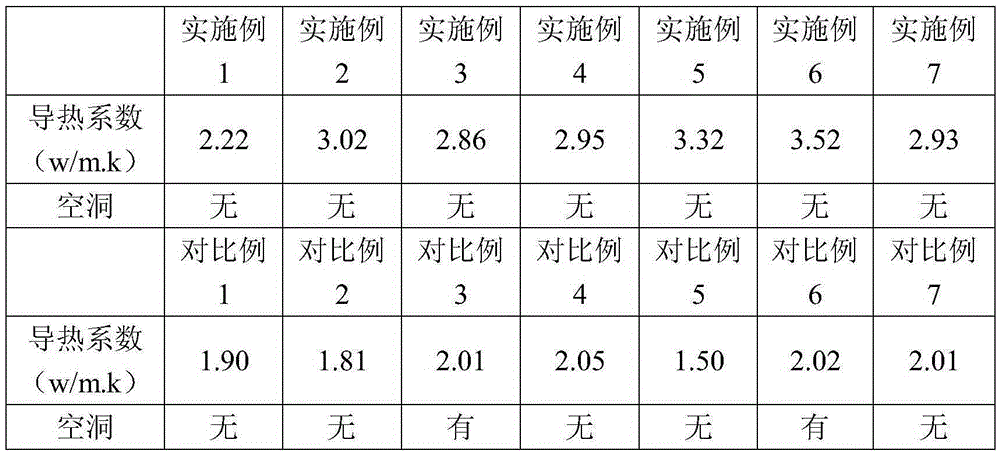

Examples

Embodiment 1

[0038] Brominated epoxy resin (55.34wt%), brominated novolak resin (26.63wt%), epoxy resin (2.77wt%), imidazole accelerator (0.11wt%, produced by Shikoku Kasei), nano Dissolve diamond (0.15wt%) and boron nitride (15wt%) in an organic solvent, mechanically stir and emulsify to prepare a 65wt% glue solution, then impregnate glass fiber cloth, and form a prepreg (prepreg) after heating and drying. Copper foil is placed on both sides, pressurized and heated to form a copper foil substrate.

Embodiment 2

[0040] Brominated epoxy resin (45.49wt%), brominated novolac resin (21.83wt%), epoxy resin (2.29wt%), imidazole accelerator (0.09wt%, produced by Japan Shikoku Kasei 2MI), nano Dissolve diamond (0.3wt%) and boron nitride (30wt%) in an organic solvent, mechanically stir and emulsify to prepare a 65wt% glue solution, then impregnate glass fiber cloth, and form a prepreg after heating and drying. Copper foil is placed on both sides, pressurized and heated to form a copper foil substrate.

Embodiment 3

[0042] Brominated epoxy resin (45.59wt%), brominated phenolic novolac resin (21.93wt%), epoxy resin (2.29wt%), imidazole accelerator (0.09wt%, produced by Japan Shikoku Kasei 2MI), nano Dissolve diamond (0.1wt%) and boron nitride (30wt%) in an organic solvent, mechanically stir and emulsify to prepare a 65wt% glue solution, then impregnate glass fiber cloth, and form a prepreg after heating and drying. Copper foil is placed on both sides, pressurized and heated to form a copper foil substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com